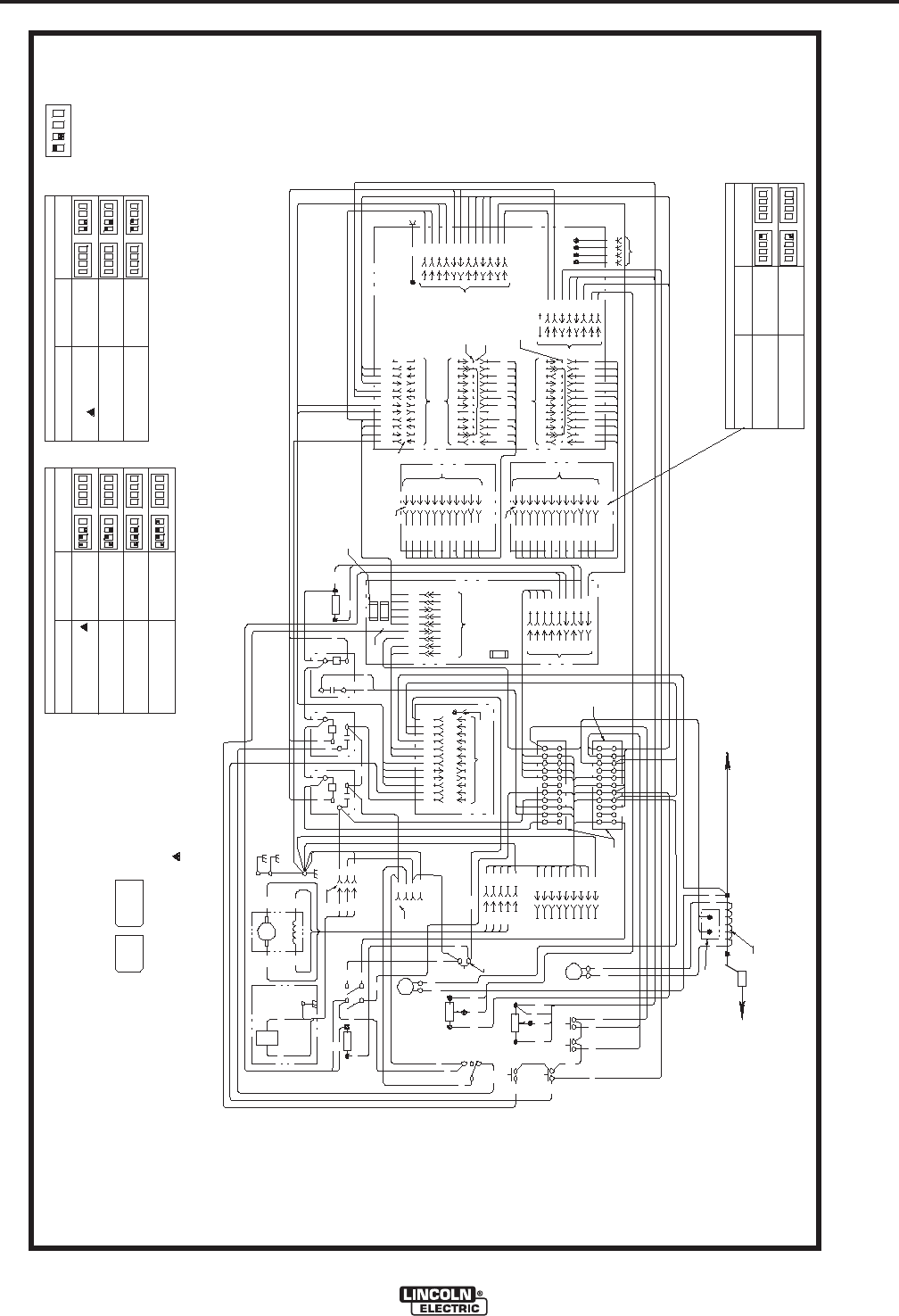

WIRING DIAGRAMS

L6489-1

A

ELECTRODE TO POWER SOURCE

WORK

517

67

593

592

592

539S

582 581

539S

634 642 641

5K

STOP

SWITCH

START

SWITCH

WIRE FEED

SPEED CONTROL

INCH UP

SWITCH

INCH DOWN

SWITCH

576 575

POWER SOURCE

OUTPUT CONTROL

10K

77

AM

517

-

+

VM

67

-

+

21

625

532

532

25

TRAVEL

SWITCH

HAND

OFF

AUTO

2

532

531A

631

532

32

531

31

53187

FLUX OR

WATER

SOLENOID

WIRE FEED MOTOR

627

539

531

531A

626

541

ARM

531

87

FLUX CONNECTOR

C

B

A

531

87

532

25

531

GND.

GND.GND.

A

B

C

D

539

627

626

A

B

C

D

GND.

E

541

539

627

626

GND.

541

A

B

C

D

E

GND.

F

G

H

I

2

4

31

32

75

21

76

77 77

76

75

21

32

31

4

2

MOTOR CONNECTOR

CONTROL CABLE TO

POWER SOURCE

585

510

589

510

682

510

532

625

CONTROL POWER

SWITCH

31

67

21

77

76

75

681

689

528

582

581

4

87

32

626

627

539

539S

510

2

541A

541

532

592

562

635

636

637

525

539

528

531A

67

21

TRAVEL

CONNECTOR

24

1

10

2

3

4

5

6

7

8

9

11

12

*

510A

2

1

10

7

9

12

6

8

11

510

610

631

532

539

541

627

626

*

539

525

539S

593

629

539

525

587

CONTROL P.C.BD.

*

586

1

2

3

4

5

6

7

8

9

250

610

510

525

629

539

636

635

641

642

75

77

1

2

3

4

6

7

8

9

11

12

76

*

75

76

*

1

2

3

4

6

7

9

10

11

12

77

635

584(S)

629

515

539

525

583(S)

75

76

*

1

2

3

4

6

7

9

10

11

12

77

635

584(C)

629

515

539

525

583(C)

5

588

1

4

6

3

2

9

8

575

576

681

634

592

682

510A

*

LOGIC

P.C.BD.

9

8

510A

510A

4

6

528

689

11 582

12 581

2 585

3 589

5562

1637

7587

10 586

531A

N.D.

TERMINAL

STRIP

N.E.

CR1

FLUX

RELAY

CR2

TRAVEL

RELAY

CR3

CONTACTOR

RELAY

N.F.

F2

F1

F3

N.G.

JUMPER

CONNECTOR "A"

JUMPER

CONNECTOR "B"

N.A.

690

694

691

692

693

*

N.B.

WORK TO POWER SOURCE

N.D. 87-531 115VAC - 1/2A SWITCHED.

N.G. THIS FUSE NOT PRESENT ON EARLIER CONTROL P.C.

BOARD MODELS.

N.B. THESE LEADS ARE NOT PRESENT ON LOGIC P.C. BOARDS

WITH DIP SWITCHES.

Methods of BurnbackMethods of Travel

Start/stop with switches

Lead #691 to P6

Lead #692 to P5

Start/stop with current

Lead #691 to P6

Lead #692 to P7

Start with current

Stop with stop switch

Lead #691 to P5

Lead #692 to P7

Start with start switch

Stop after crater fill

(Crater fill board installed)

Lead #691 to P8

Lead #692 to P9

For earlier logic P.C.

Boards with jumpers

tcennoCseY

Lead #694 to P10

tcennoCoN

Lead #694 to P8

Wire feed stop & contactor

delay

Lead #693 to P3

Lead #690 to P4

Inch up & contactor delay

Lead #693 to P1

Lead #690 to P4

Inch up & no contactor

delay

Lead #693 to P1

Lead #690 to P2

Crater board installed?

SWITCH #1

1234

SWITCH #2

1234

SWITCH #1

1234

SWITCH #2

1234

For Logic P.C. Boards with

dip switches

(Remove jumper connector "B"

from 584(c) to 583(c))

(Install jumper connector "B"

from 584(c) to 583(c))

For earlier logic P.C.

Boards with jumpers

Connect

Connect

SWITCH #1

1234

SWITCH #2

1234

SWITCH #1

1234

SWITCH #2

1234

For Logic P.C. Boards with

dip switches

Connect

Connect

SWITCH #1

1234

SWITCH #2

1234

SWITCH #1

1234

SWITCH #2

1234

N.A. WHEN START P.C. BOARD IS INSTALLED, JUMPER CONNECTOR "A" IS REMOVED.

Use of crater fill board

For earlier logic P.C.

Boards with jumpers

Connect

Connect

SWITCH #1

1234

SWITCH #2

1234

SWITCH #1

1234

SWITCH #2

1234

For Logic P.C. Boards with

dip switches

Connect

SWITCH #1

1234

SWITCH #2

1234

5641

N.F. JUMPER LEAD TO BE CONNECTED TO PIN "H" AT ALL TIMES.

UNIT SHIPPED WITH LEAD IN THIS POSITION.

1/2A SLOW BLOW FUSE

3/10A FUSE

3/10A FUSE

641

518

N.C.

11

22

33

44

1

2

3

4

CURRENT TRANSFORMER

518

539S528

CR4

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

10

11

12

INDICATES CONNECTOR CAVITY NUMBERS

*

CAVITY NUMBERING SEQUENCE

(COMPONENT SIDE OF P.C. BOARD)

NA-4 SHIPPED WITH LOGIC P.C. BOARD

SET FOR INDICATED MODE OF TRAVEL

AND BURNBACK.

NA-4 WITH CURRENT CONTROL RHEOSTAT

ELECTRICAL SYMBOLS PER E1537.

VARIABLE VOLTAGE P.C.BD.

N.C. 531-532 115VAC; 531-25 115VAC (SWITCHED) - 250 VA

5 AMP

CIRCUIT

BREAKER

CURRENT SENSOR

P. C. BOARD

588

515

635

539

629

525

584(C)

583(C)

76

77

75

515

635

539

629

525

584(S)

583(S)

76

77

75

11

12

9

8

10

5

6

4

3

7

START P.C.BD. (OPTIONAL)

CRATER FILL P.C.BD.

(OPTIONAL)

*

11

12

9

8

10

5

6

3

4

1

*

7

N.E. ON EARLIER UNITS, LEAD #689 WAS LOCATED BETWEEN #31 and #67

(FORMERLY #5), LEAD #510 WAS LOCATED BETWEEN #87 & #32, AND

LEAD #31 WAS LOCATED NEXT TO #681. CAREFULLY NOTE LEAD POSITIONS

BEFORE MAKING ANY CONNECTIONS TO TERMINAL STRIP.

GND

539

8

GND

8

GND10

GND

2

N.J.

GND

2

N.J.

N.H.

N.H. THIS LEAD PRESENT ON CODE 10318 AND HIGHER.

N.K.

N.J. THESE LEADS ARE NOT PRESENT ON EARLIER START

AND CRATER FILL P.C. BOARDS.

N.K. ALL FUSES WERE REPLACED WITH PTC RESETTABLE

FUSES ON LATER CONTROL P.C. BOARDS.

DOOR

SUBPANEL

1234

SWITCH EXAMPLE

SWITCH POSITION 1 IS UP

SWITCH POSITION 2 IS DOWN

SWITCH POSITIONS 3 AND 4 ARE NOT APPLICABLE

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual. The specific diagram for a particular code is pasted inside

the machine on one of the enclosure panels. If the diagram is illegible, write to the Service Department for a replacement. Give the equipment code number.