WIRING

1. OV DC (WHT)

2. +24V DC (RED)

3. Complete (GRN)

4. Start (ORG)

5. Spray (BLK)

6. Error (BLU)

Power REAM

[2]

A CLOSER LOOK

www.lincolnelectric.com

PERFORMANCE

• Powerful constant torque drive system provides non-stall capability.

The motor travels with the reaming bit, a design feature that aids

reliability and extends motor service life, up to 2.4 million cycles.

• Reaming bits are precision manufactured from tool steel with

titanium nitride coating.

• Dry-run feature helps prevent accidental damage to the unit.

• Synchronous timing belt does not allow slippage, avoiding excessive

belt wear.

• Wire cutter jaws designed for up to 90,000 cycles.

• One-year warranty on parts and labor.

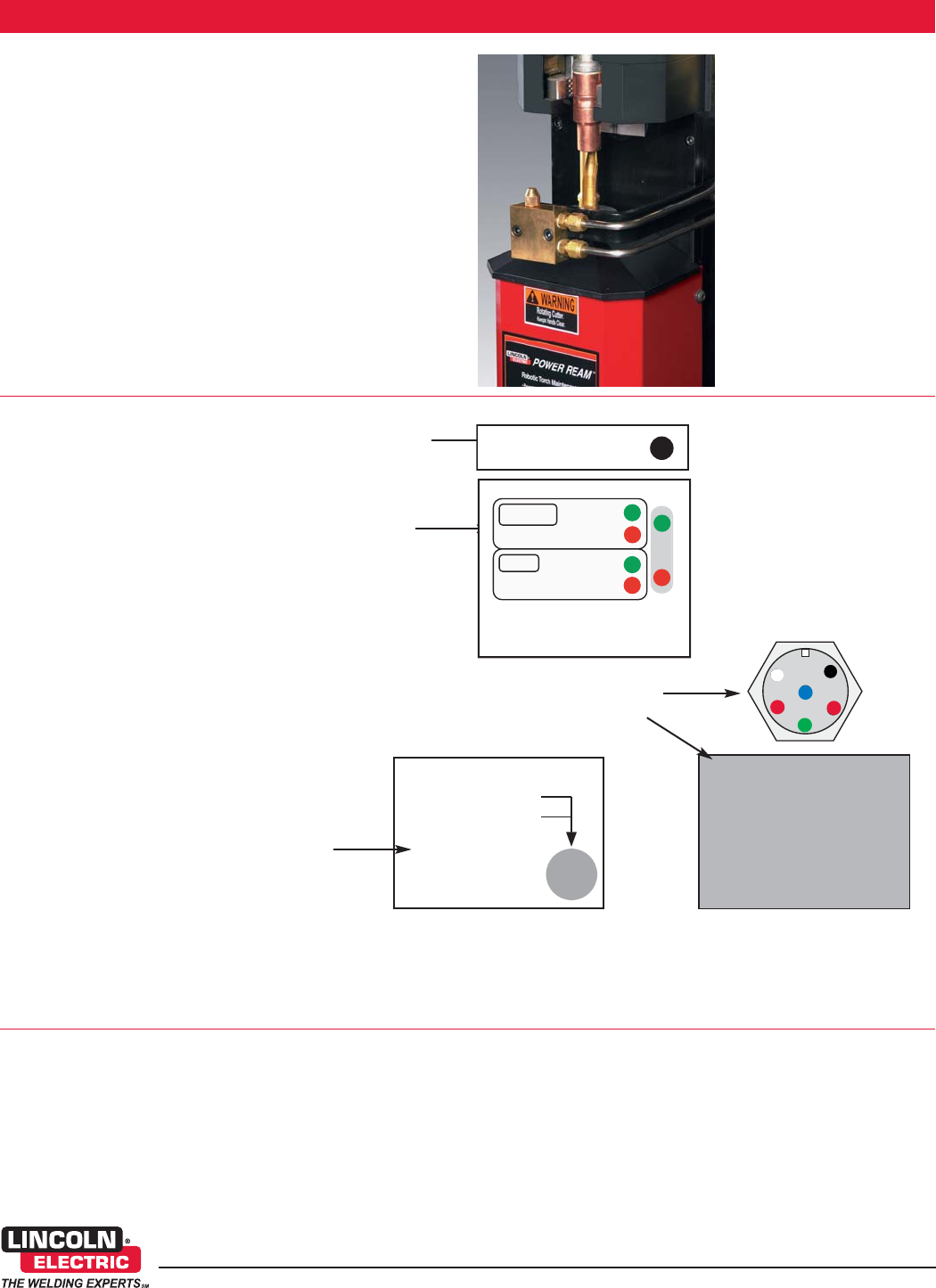

KEY CONTROLS

1 Fail-safe reset pushbutton overrides the

microcontroller’s commands to the cylinders

and sends them back to their home position.

2 Diagnostic LEDs are visible to an operator

and provide an indication of the position of

the air cylinders. If an error occurs, corre-

sponding flash error codes make trou-

bleshooting much easier.

3 “No Error” programming: The setup push-

button is used to sequence the reamer sole-

noids for easy programming of the correct

position the very first time. Subsequent

pressing of the button will raise the reaming

head (without spinning the ream bit), then

grip and release the nozzle.

4 Easy configuration of sinking vs. sourcing

inputs and outputs. No need to open the

case to set internal dip-switches during

installation!

-Error signal feedback to the robot: If an

error occurs in the process, then the

Power REAM returns to its home

position and sends an error signal to

the robot.

Setup Sequencer

Press to Clamp

Hold to Raise

1

3

2

QUALITY AND RELIABILITY

4

RESET

Clamp

Open

Closed

Lift

Top

Bottom

For flashing diagnostic codes,

refer to operator manual.

The Power REAM controls the entire reaming process with its internal

microcontroller. Every aspect of the reaming cycle is commanded,

monitored and checked by the controller. The feedback signal to the

robot is a true “complete” signal indicating that the entire sequence has

been executed without error.