TECHNOLOGY

2/8

Waveform Control Technology

Waveform Control Technology

is the ability to customize

waveform output. It is the ability

to choose a weld program from

a pre-defined set of programs,

and to manipulate the

parameters of that program

to best fit your application.

Lincoln Electric strives to

understand the customer’s

needs in order to make the job

easier. That is why Waveform

Control Technology was

designed: to empower the

people who use the equipment,

our customers.

Waveform Control Technology

allows the user to choose from

a library of pre-programmed

weld “modes” that have been

developed by expert welders.

Then, Waveform Control

Technology offers the

opportunity to change those

What

is Waveform Control?

The future of welding is here.

®

There are many physical forces that affect the welding arc and the transfer of metal from the electrode to the

weld puddle. Surface tension, magnetic, and aerodynamic forces are the most significant. The welding current

directly affects the magnetic and aerodynamic forces in the welding arc. The welding current and surface tension

forces can be balanced to control metal transfer within the arc.

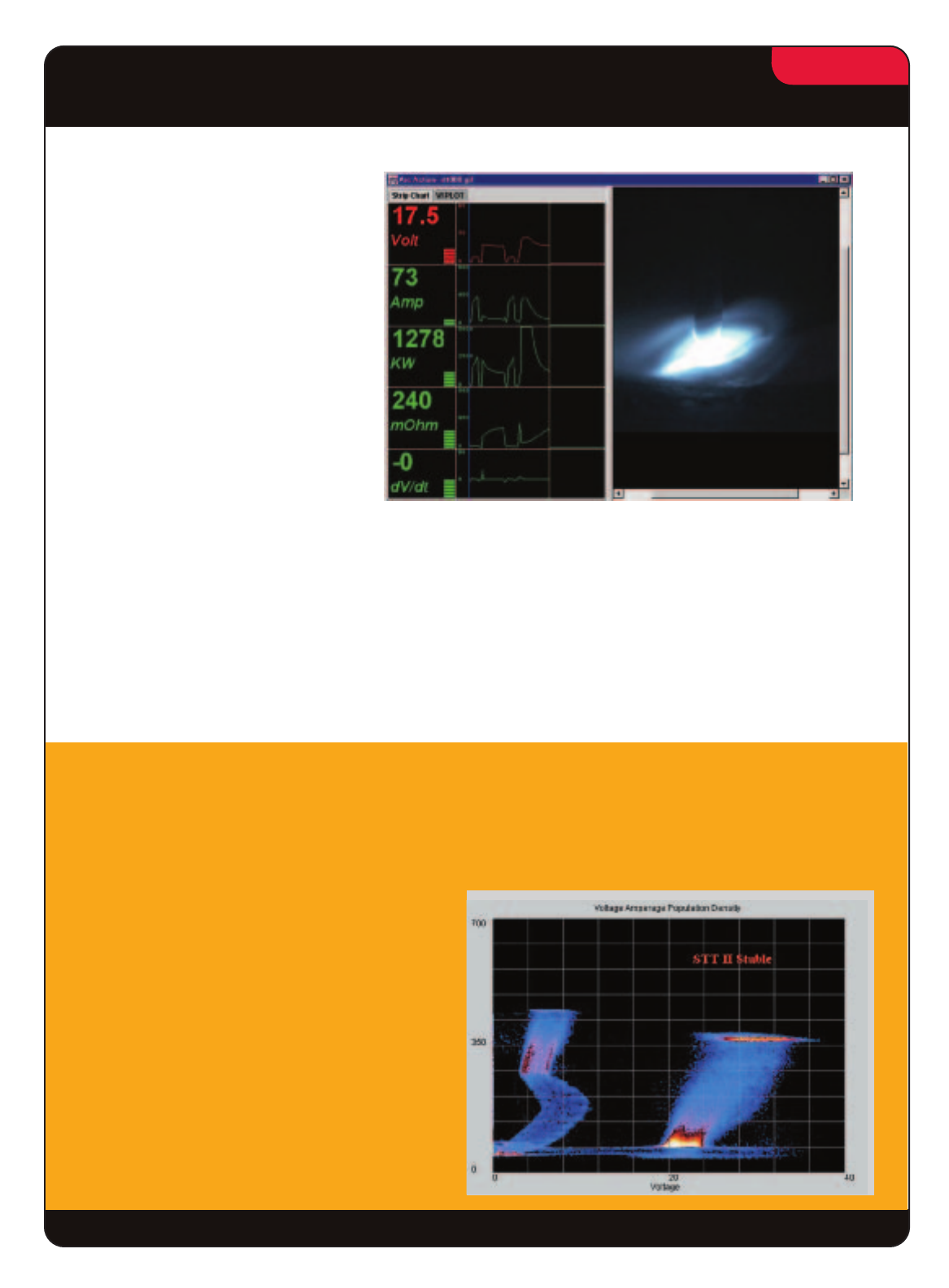

High-speed electronics monitor the electrical signals

from the welding arc and make appropriate changes

to the current waveform. The electronics must be

fast, accurate, and rugged to control the arc and

withstand the harsh welding environment.

How

Waveform Control Works

Amperage

values, within a programmed range,

to find the combination of wire feed

speed, voltage, current, and arc

control that the application requires.

But Lincoln has even taken it one

step further. Waveform Control

Technology also provides the ability

to use a single source to perform

Stick, TIG, MIG/MAG, Flux-cored,

and Submerged Arc welding

procedures. With a Waveform

Control Technology product, the

days of configuring different systems

to make different welds are over.

The Arc Action Tool shows the behavior of the arc in the form of a Voltage/Amperage

(VI) plot. To further illustrate what the changes in voltage and current mean to the arc,

Lincoln Electric uses high-speed photography to capture arc behavior.