Pro-Cut 80

www.lincolnelectric.com

FEATURES

• One control dial with current indicators for easy operation and

setup.

• Air pressure regulator, air filter and pressure gauge are standard.

Pressure gauge is right on the control panel for easy setup.

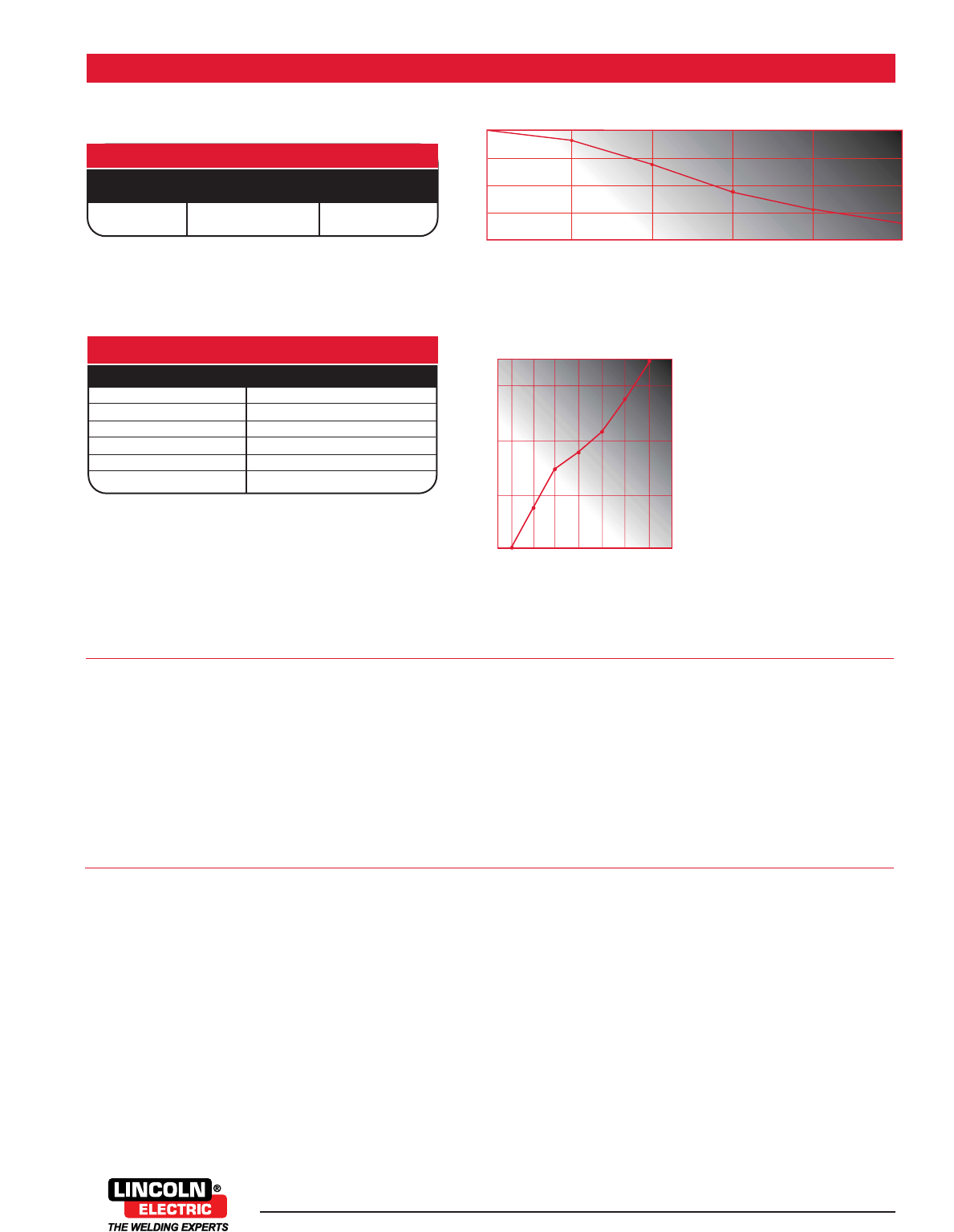

CUT CAPACITY DATA

ELECTRODE LIFE TEST DATA

(2)

0

0.500.375

0.625

MtlThi k (I h )

0.75

1.0 1.25

10

20

30

40

0

0

60

120

180

20

40

60

Electrode Pit Depth (X.001 Inch)

Time in HoursTime in Hours

0.5

1.0

CUTTING CAPACITY

Ordering Information Description

KP2063-1B1 Electrode

KP2062-2B1 VORTECH™ Nozzle (.043)

(1)

KP2062-3B1 VORTECH™ Nozzle (.053)

KP2062-5B1 VORTECH™ Nozzle (.082) Gouging

KP2064-1 Shield Cup

KP2065-1 Drag Cup

EXPENDABLE PARTS

(1)

.043 Nozzle can be used when cutting at 60 amps or lower for a

smaller kerf.

A CLOSER LOOK

PERFORMANCE

QUALITY AND RELIABILITY

• Parts-In-Place safety indicator and lockout circuit to protect both

the operator and the system.

• Thermostatically protected against overheating.

• Line voltage compensation.

•Manufactured under a quality system certified to ISO 9001

requirements.

• Three-year warranty on parts and labor. (1 year warranty on

plasma torch.)

Number of Starts (20 Sec. Arc/Start)

(2)

Electrode erosion of .060” is typically end of

electrode life.

Metal Thickness (inches)

Time in Hours

IPM (80% Max. Speed)

Electrode Pit Depth (X.001 inch)

[2]

Production Recommended Maximum

Capacity Capacity Capacity

3/4" @ 18 IPM 1" @ 11 IPM 1-1/4" @ 7 IPM