Invertec® STT® II

[2]

A CLOSER LOOK

www.lincolnelectric.com

Waveform Control Technology®

Driving Superior Welding Performance

Lincoln’s Waveform Control Technology controls and shapes the output waveforms

(or weld modes) to adapt to virtually any application, material or weld position. Waveform

Control Technology makes it possible to take advantage of Lincoln Nextweld innovations like

the STT Process using the STT II.

For more information see Nextweld Document NX-1.10

WHAT IS NEXTWELD

®

?

Nextweld integrates Lincoln’s technologies, process-

es and products to create a comprehensive, flexible,

user-friendly welding system that can increase

efficiency and reduce fabrication costs. Waveform

Control Technology™ and digital communications

provide the foundation for Nextweld innovations like Pulse-On-

Pulse™, Power Mode™, STT

®

and ArcLink

®

. Look for Nextweld

for ultimate arc control, high efficiency/reliability and seamless

system integration.

STT

®

(Surface Tension Transfer

®

) is a controlled

GMAW short circuit transfer process that uses

current controls to adjust the heat independent of

wire feed speed, resulting in superior arc perform-

ance, good penetration, low heat input control,

and reduced spatter and fumes.

For more information see Nextweld

Document NX-2.20

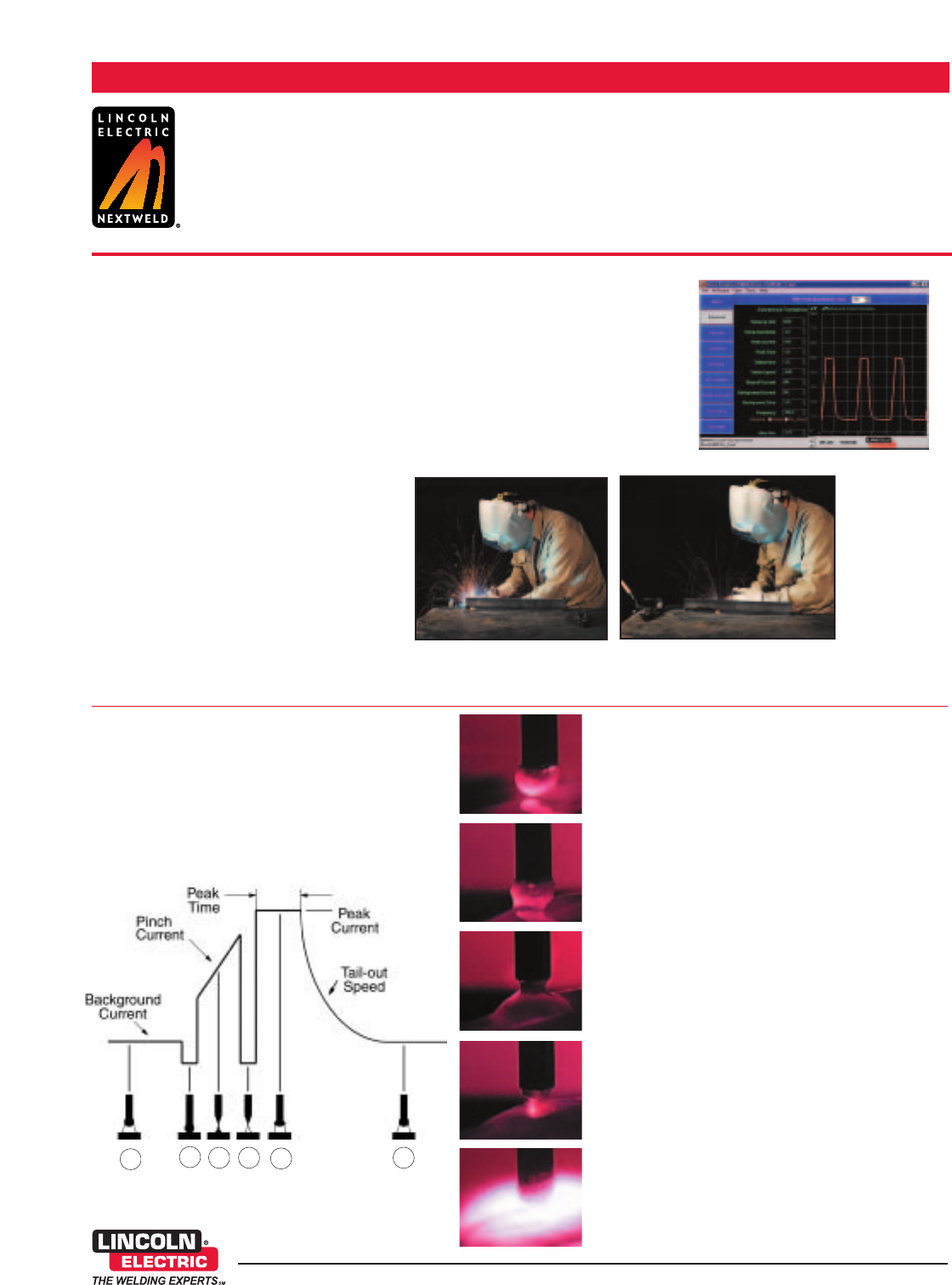

Conventional CV short

circuit transfer using CO

2

and .045” solid wire.

STT using CO

2

and .045” solid wire.

Note reduced spatter and fume.

A. STT produces a uniform molten ball and maintains it

until the "ball' shorts to the puddle.

B. When the "ball" shorts to the puddle, the current is

reduced to a low level allowing the molten ball to wet

into the puddle.

C. Automatically, a precision PINCH CURRENT wave

form is applied to the short. During this time,

special circuitry determines that the short is about

to break and reduces the current to avoid the spatter

producing "explosion".

D. STT circuitry re-establishes the welding arc at a low

current level.

E. STT circuitry senses that the arc is re-established, and

automatically applies PEAK CURRENT, which sets the

proper arc length. Following PEAK CURRENT, internal

circuitry automatically switches to the BACKGROUND

CURRENT, which serves as a fine heat control.

The STT Process

AEDCBA