Invertec

®

V450-PRO

www.lincolnelectric.com

[4]

A CLOSER LOOK

TIME

WELDING CURRENT

Background

Peak

Ramp Up

Tail Out

Step Off

PULSE CYCLE

Low Heat

(Background)

High Heat

(Peak)

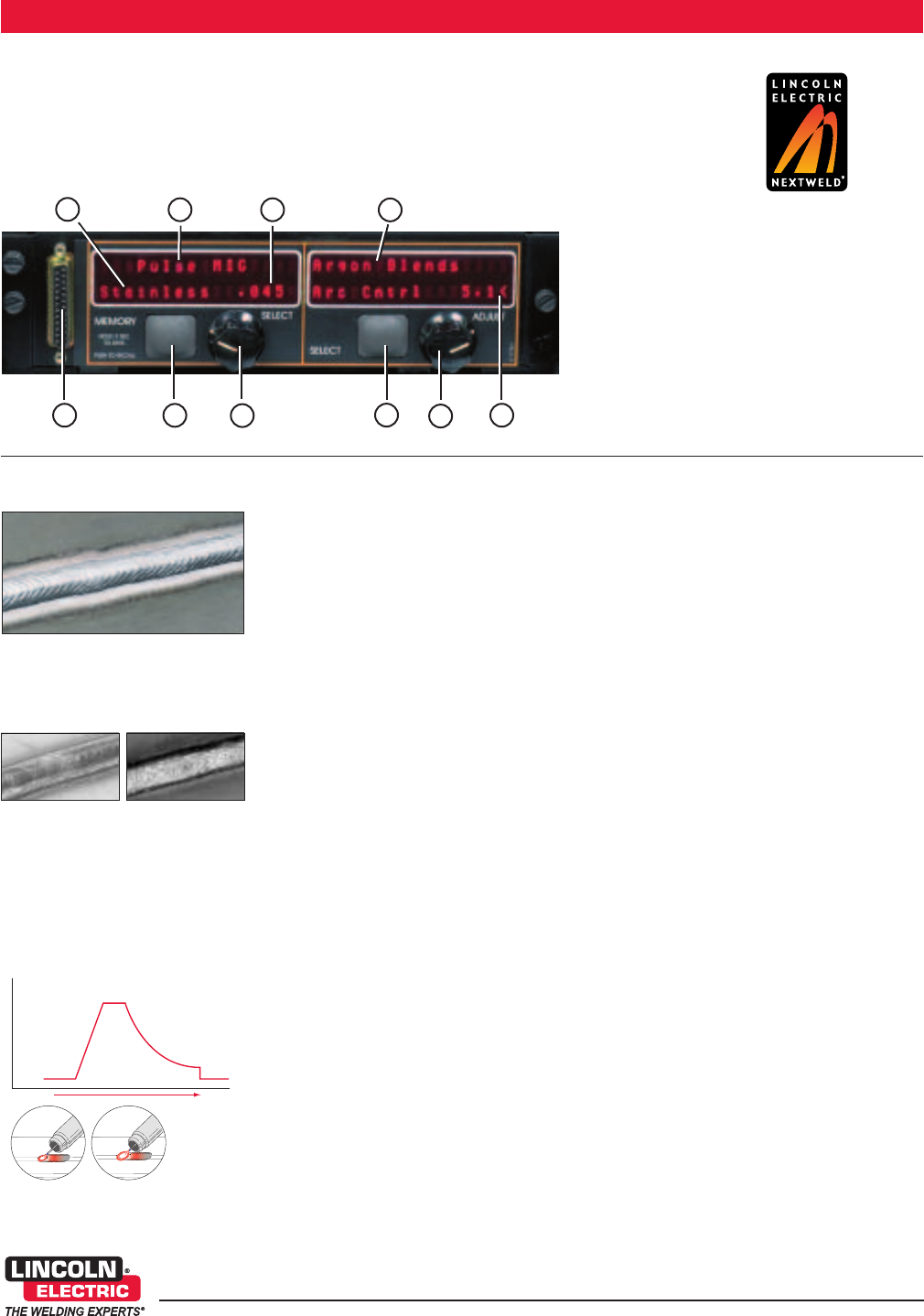

Key Controls

T ) Serial Port for Software Updates

U ) Weld Mode Memory Set Button

V ) Weld Mode Select Knob

W ) Hot Start/Arc Control Select Button

X ) Hot Start/Arc Control Parameters Adjust Knob

Y ) Arc Control Setting

Z ) Shielding Gas Type

AA ) Consumable Diameter

AB ) Process

AC ) Material Type

O

PTIONAL ADVANCED PROCESS PANEL KIT

Add the Advanced Process Panel to gain access to Lincoln’s Nextweld

®

Innovations, including

Pulse-On-Pulse

®

, Power Mode

®

, Pulsed MIG.

U

V

W

X

Pulse-On-Pulse

®

on 3mm Aluminum

Power Mode

®

reduces

spatter and improves

bead appearance, even

for low voltage

procedures on

stainless.

Power Mode

®

aids

bead wetting

and penetration

on aluminum.

Pulsed MIG

• Varies weld current between peak (high heat) and background (low heat) current to provide

better control of heat input.

• Reduces warping and burnthrough on thin materials.

• Enables in-the-flat, horizontal, vertical up, or overhead welding without a slag system. It can be

used in hard automation, robotic, and semiautomatic applications.

• Optimized GMAW-P waveforms are available to use on aluminum, carbon steel, high strength

low alloy steel, stainless steel, and nickel alloys.

For more information see Nextweld

®

Document NX-2.70

Pulse-On-Pulse

®

• Uses a sequence of varying pulse wave shapes to produce a TIG-like bead appearance

and excellent weld properties when MIG welding aluminum.

• Pulse-On-Pulse

®

controls arc length and heat input together, making it easier to achieve

good penetration.

For more information see Nextweld

®

Document NX-2.10

Power Mode

®

• Uses high-speed regulation of output power to deliver extremely fast response to changes in the

arc, for example, when using a whip technique.

• Improved MIG welding performance, including low spatter, very uniform, consistent bead wetting

and controlled penetration.

• Great for low voltage applications on thin steel and stainless steel material less than

20 gauge (0.7 mm).

• Delivers excellent arc characteristics on aluminum and other alloys such as silicon bronze and

nickel alloys.

For more information see Nextweld

®

Document NX-2.60

• Displays gas, mode and wire size for easy setting and monitoring.

• Eight memories to quickly switch between weld modes.

T

Y

AA

Z

A

B

AC