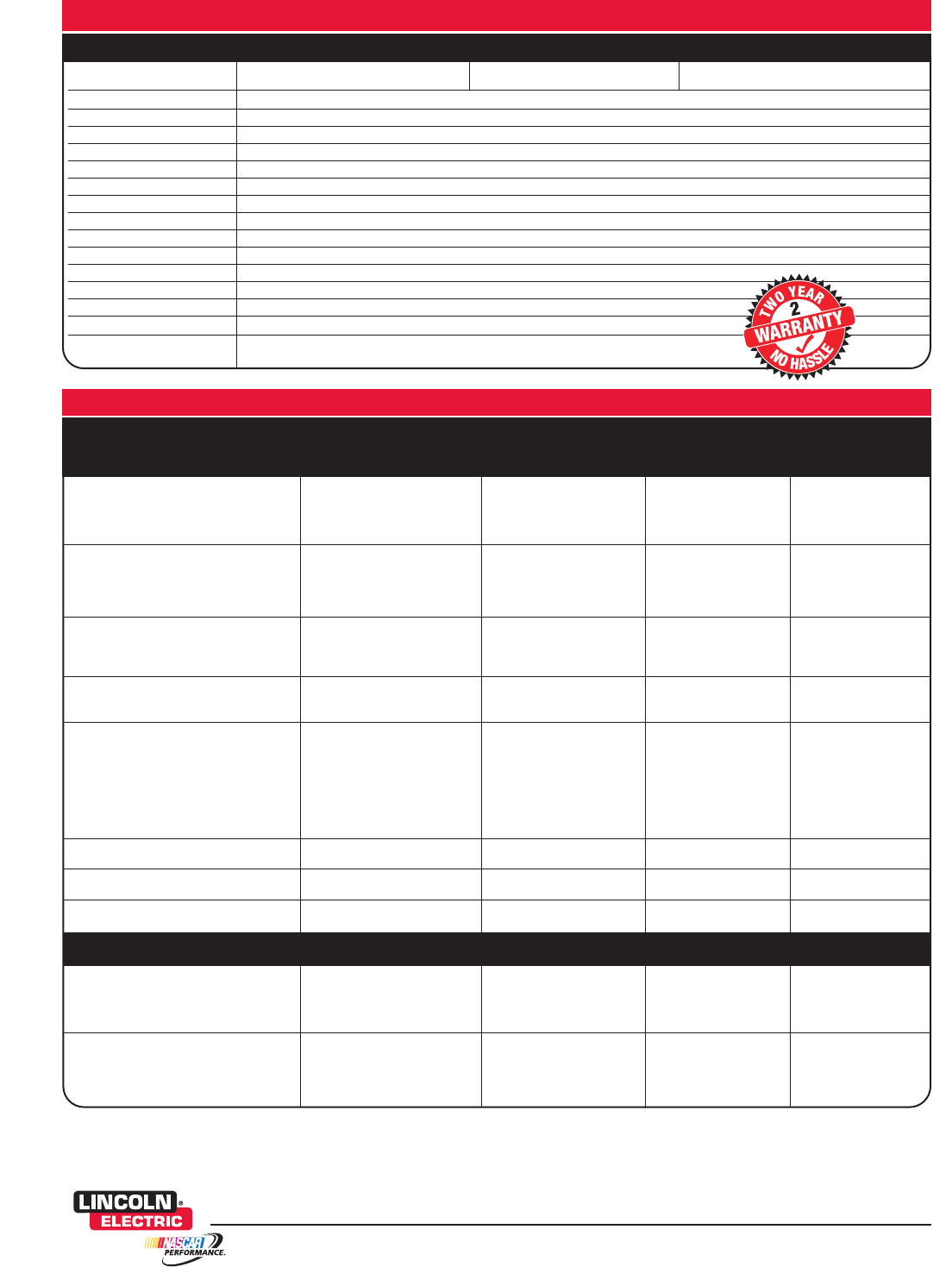

SPECIFICATIONS

Vista™ Welding Helmets

www.lincolnelectric.com

GUIDE FOR SHADE NUMBERS

VISTA

™

3000 VISTA

™

2000 VISTA

™

1000

View Size 3-7/8” x 3-1/8” (98mm x 81mm) 3-7/8” x 1-7/8” (96mm x 48mm) 3-3/4” x 1-3/8” (94mm x 35mm)

Cartridge Size 5-1/4” x 4-1/2” (133mm x 114mm)

Light to Dark Speed: 0.1 Milliseconds

Light State: 3

Dark State: 9-13

Dark to Light Delay: 0.1 & 2.0 Seconds

Variable Sensitivity: Grind/TIG

TIG Sensitivity 5 Amps

Arc Sensors: 4

Power Supply: Solar Panels

Eye Protection: EV/IR to Shade 16

Enclosure: Waterproof and Dustproof

Operating Temperature: +14° F (-10° C) to +148° F (64° C)

Storage Temperature: Room Temperature

Compliance: ANSI Z87.1, CSA Z94.3

Warranty 2 Year

OPERATION ELECTRODE SIZE ARC MINIMUM SUGGESTED

(1)

in. (mm) CURRENT PROTECTIVE SHADE NO.

(AMPERES) SHADE (COMFORT)

Shielded metal arc Less than 3/32 (2.4) Less than 60 7–

welding (SMAW) 3/32 - 5/32 (2.4–4.0) 60-160 8 10

5/32 - 8/32 (4.0–6.4) 160-250 10 12

More than 1/4 (6.4) 250-550 11 14

Gas metal arc welding (GMAW) Less than 60 7–

and flux cored arc welding (FCAW) 60-160 10 11

160-250 10 12

250-500 10 14

Gas tungsten arc welding (GTAW) Less than 50 8 10

50-150 8 12

150-500 10 14

Air carbon arc cutting (CAC-A) (Light) Less than 500 10 12

(Heavy) 500-1000 11 14

Plasma arc cutting (PAC) Less than 20 44

20-40 55

40-60 66

60-80 88

80-300 89

300-400 9 12

400-800 10 14

Torch brazing (TB) ––3 or 4

Torch soldering (TS) ––2

Carbon arc welding (CAW) ––14

PLATE THICKNESS

in. mm

Oxyfuel gas welding (OFW)

Light Under 1/8 Under 3 4 or 5

Medium 1/8 to 1/2 3 to 13 5 or 6

Heavy Over 1/2 Over 13 6 or 8

Oxygen cutting (OC)

Light Under 1 Under 25 3 or 4

Medium 1 to 6 25 to 150 4 or 5

Heavy Over 6 Over 150 5 or 6

(1)

As a rule of thumb, start with a shade that istoo dark, then go to alighter shade which gives sufficient

view of the weld zone withoutgoing below the minimum. In oxyfuel gas welding or cutting where the torch

produces a high yellowlight, it is desirable to use a filter lens that absorbs the yellow or sodium linethe

visible light of the (spectrum) operation

Shade numbers are givenas a guide only and may be varied to suit individualneeds.

[3]

Data from ANSI Z49.1-2005