3

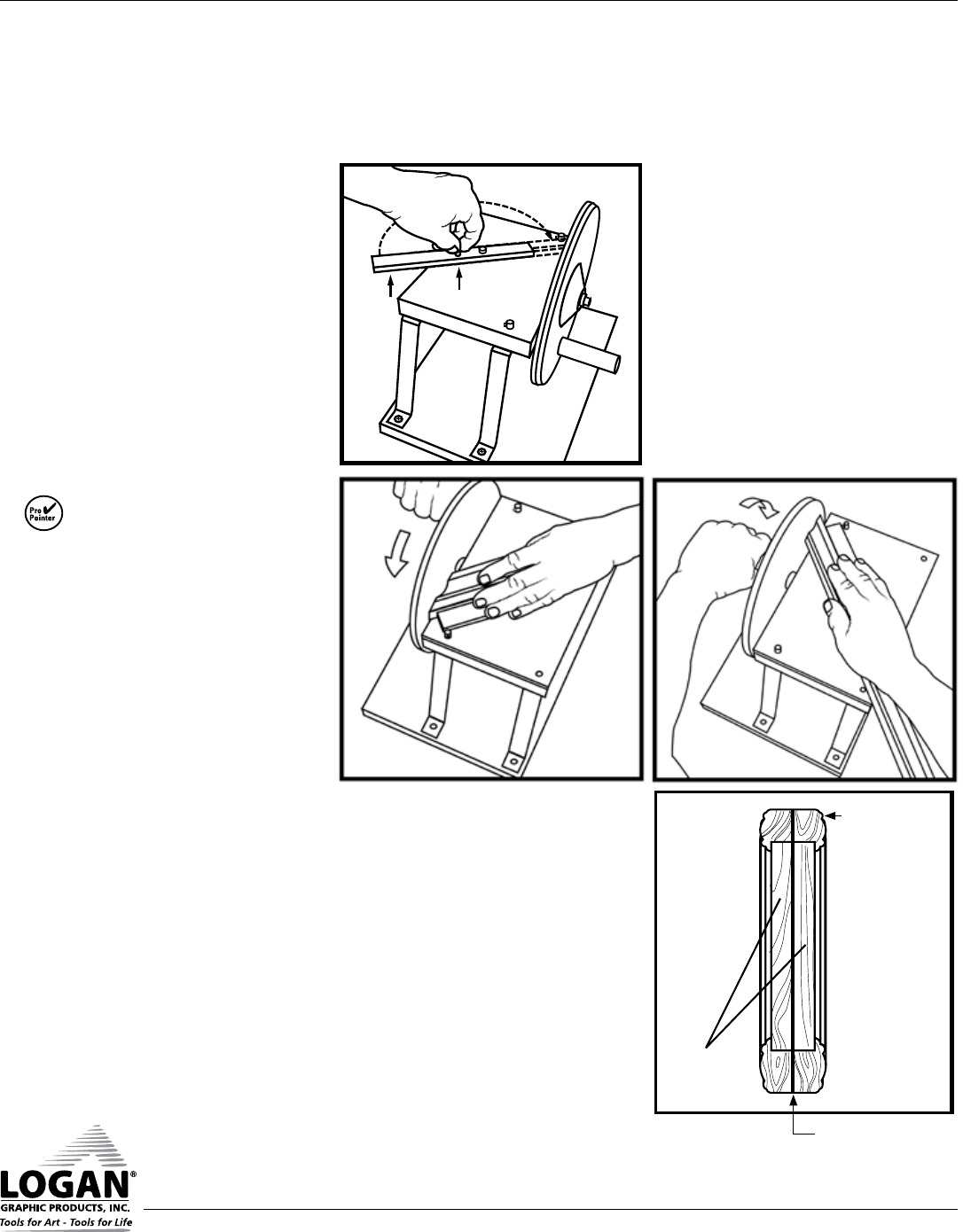

Fig. 3

Moulding

Pieces

Fig. 4a

Left Side

Check top

Align Bottom

Fig. 4b

Right Side

Fig. 5

Instruction Manual

Model F200-2

Precision SANDER ELITE

Operation

Preparation

1. Rotate alignment bar to either side

by lifting and turning (Fig. 3)

Sanding

1. Place back of moulding against

alignment bar with finish side up.

2. Slide moulding against wheel.

3. With one hand, hold moulding firmly

against alignment bar and wheel.

With other hand, rotate wheel

in the direction of the moulding

or downward onto the top of the

moulding.

(Figs. 4a and 4b)

4. Rotate wheel 4-6 times.

• Adjust the pressure against

the wheel while rotating. Start

with light pressure until wheel

is spinning, then increase the

pressure for easier sanding.

5. Check sanded surface of moulding

to see if surface is smooth.

6. Repeat until full surface is smooth.

Check Lengths It is important both sides of

moulding are same length for square frame

and seamless corners.

1. Lay two moulding pieces side-by-

side so miters are facing up.

2. Align the two lower edges.

3. Check to see if the upper edges are

even in length (Fig. 5).

4. If not, sand longer piece until it’s

even with short piece.

Logan Graphic Products Inc., 1100 Brown Street, Wauconda, IL 60084 847-526-5515 www.logangraphic.com