Fastening torque adjustment

I

0

The fastening torque may be adjusted by

turning the adjustment ring to align the

notched line on the ring with

a

number

on the indicator label. However, the

clearance between the ring and the cap

is

2.5

mm

(1/8")

maximum after one full

turn, and the ring should not be forced

beyond this point.

0

Turning the adjustment ring in the arrow

direction obtains

a

higher torque

(HI

side); turning in the opposite direction

gives

a

lower torque

(LOW

side).

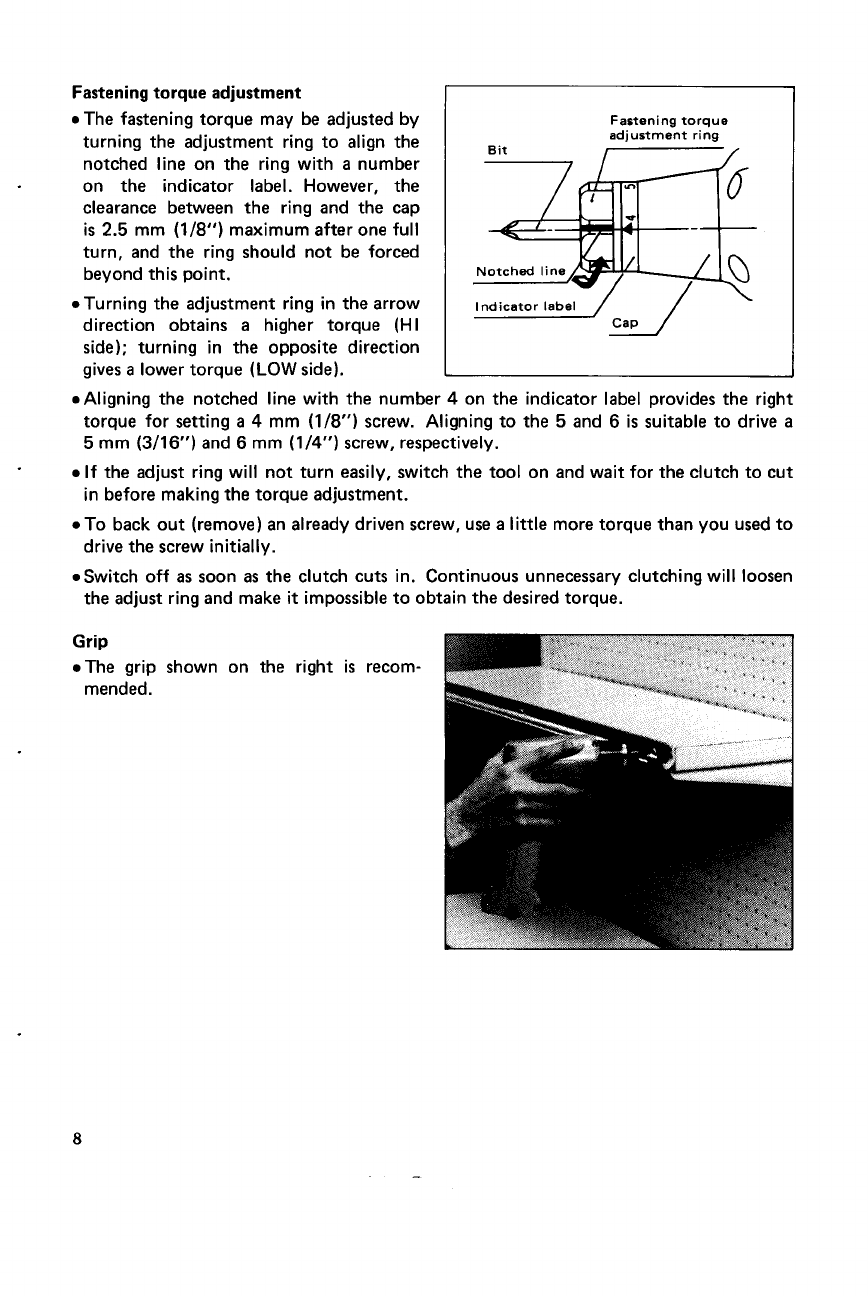

Fastening torque

adjustment ring

Bit

.Aligning the notched line with the number

4

on the indicator label provides the right

torque for setting

a

4

mm

(1/8")

screw. Aligning to the

5

and

6

is

suitable to drive

a

5

mm

(3/16")

and

6

mm

(1/4")

screw, respectively.

0

If

the adjust ring will not turn easily, switch the tool on and wait for the clutch to cut

in before making the torque adjustment.

.To back out (remove) an already driven screw, use

a

little

more torque than you used to

drive the screw initially.

.Switch off

as

soon

as

the clutch cuts in. Continuous unnecessary clutching will loosen

the adjust ring and make

it

impossible to obtain the desired torque.

-

Grip

.The grip

mended.

shown on

the right

is

recom-

8