7

Installing or removing driver bit or socket bit

Use only the driver bit or socket bit shown in the figure. Do

not use any other driver bit or socket bit.

To install the bit, pull the sleeve in the direction of the arrow

and insert the bit into the sleeve as far as it will go. Then

release the sleeve to secure the bit.

To remove the bit, pull the sleeve in the direction of the arrow

and pull the bit out firmly.

NOTE:

• If the bit is not inserted deep enough into the sleeve, the

sleeve will not return to its original position and the bit

will not be secured. In this case, try re-inserting the bit

according to the instructions above.

OPERATION

Hold the tool firmly and place the point of the driver bit in the

screw head. Apply forward pressure to the tool to the extent

that the bit will not slip off the screw. Start the tool slowly and

then increase the speed gradually. Release the switch trigger

just as the screw bottoms out.

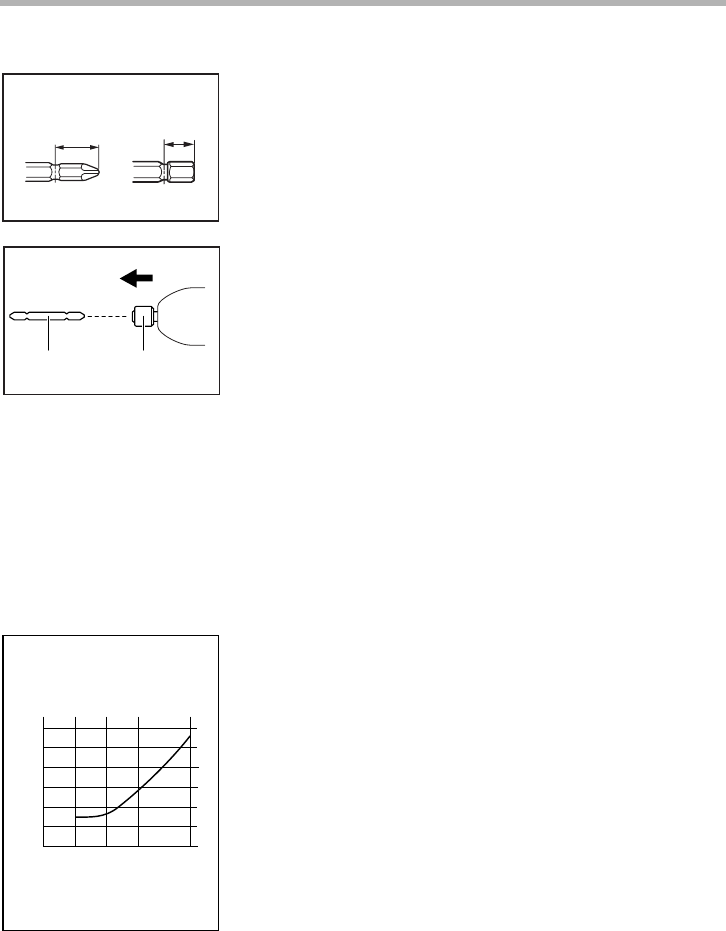

The proper fastening torque differs depending upon the kind

or size of the screw/bolt, the material of the workpiece to be

fastened, etc. Refer to the figure for the relation between fas-

tening time and wood screw size. (Material to be fastened:

Lauan)

NOTE:

• Use the proper bit for the head of the screw/bolt that you

wish to use.

• When fastening tool screws in a steel plate, the proper

fastening torque can be obtained in an extremely short

time (approx. 0.1 - 0.2 seconds). Turn the tool off as

soon as the impact sound is heard.

• Hold the tool pointed straight at the screw or the screw

and/or bit may be damaged.

• When driving wood screws, predrill pilot holes to make

driving easier and to prevent splitting of the workpiece.

12 mm

(15/32”)

9 mm

(3/8”)

001266

1. Bit

2. Sleeve

1 2

001267

6

5

4

3

2

1

ø3.8

x 50

ø4.0

x 65

ø4.2

x 90

ø4.5

x 120

mm

(S)

Fastening time

Screw size

002839