12

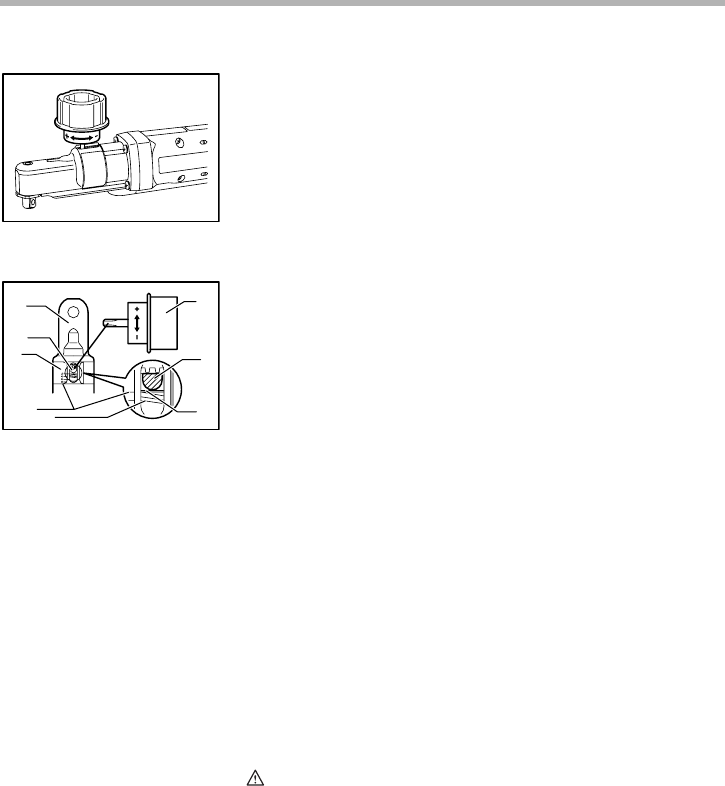

Adjusting the fastening torque

When you wish to drive machine screws, wood screws, hex

bolts, etc. with the predetermined torque, adjusting the fas-

tening torque as follows.

1. First remove the battery cartridge from the tool.

2. Loosen the screws securing the light cover.

3. Rotate the ring in the front of the tool by hand so that a

hole can be seen below the ring.

4. Place the battery cartridge in place and pull the switch

trigger. Release it so that the adjusting ring rotates and

becomes visible in the hole. And then remove the battery

cartridge.

5. Use an optional adjusting grip to adjust the fastening

torque. Insert the pin of the adjusting grip into the hole in

the front of the tool. And then, turn the adjusting grip

clockwise to set a greater fastening torque, and counter-

clockwise to set a smaller fastening torque.

6. Align the yellow line with your desired number on the fas-

tening torque scale.

7. Insert the battery cartridge and be sure that a fastening

torque has been set up by using a fastening torque

tester.

8. Tighten the screws to secure the light cover and then

rotate the ring in front of the tool until the ring is locked.

NOTE:

• Numbers on the fastening torque scale is a guideline to

set up your desired fastening torque.

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and the

battery cartridge is removed before carrying out any

work on the tool.

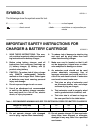

Selecting correct socket

Always use the correct size socket for bolts and nuts. An

incorrect size socket will result in inaccurate and inconsistent

fastening torque and/or damage to the bolt or nut.

003621

1. Angle head

2. Adjusting ring

3. Ring

4. Sclae

5. Adjusting grip

6. Hole for Adjusting grip

7. Yellow line

8. Compression spring

1

2

3

4

8

5

6

7

003622