7

OPERATION

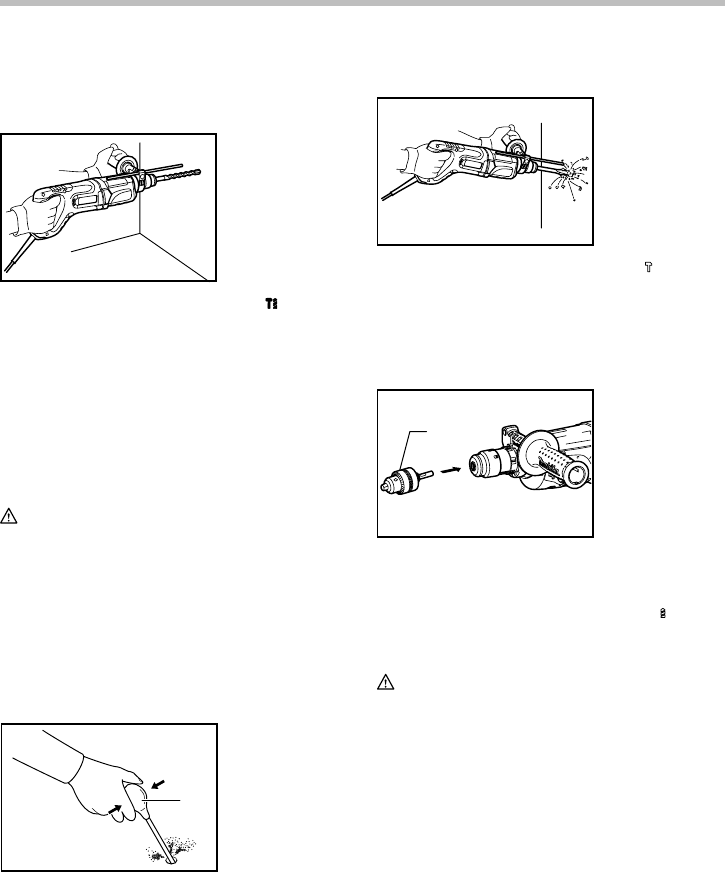

Hammer drilling operation

010167

Set the action mode changing knob to the symbol.

Position the bit at the desired location for the hole, then

pull the switch trigger.

Do not force the tool. Light pressure gives best results.

Keep the tool in position and prevent it from slipping

away from the hole.

Do not apply more pressure when the hole becomes

clogged with chips or particles. Instead, run the tool at an

idle, then remove the bit partially from the hole. By

repeating this several times, the hole will be cleaned out

and normal drilling may be resumed.

CAUTION:

• There is tremendous and sudden twisting force

exerted on the tool/bit at the time of hole

break-through, when the hole becomes clogged

with chips and particles, or when striking reinforcing

rods embedded in the concrete. Always use the

side grip (auxiliary handle) and firmly hold the tool

by both side grip and switch handle during

operations. Failure to do so may result in the loss of

control of the tool and potentially severe injury.

Blow-out bulb

1

001302

Use the blow-out bulb to clean out the hole.

Chipping/Scaling/Demolition

010168

Set the action mode changing knob to the symbol.

Hold the tool firmly with both hands. Turn the tool on and

apply slight pressure on the tool so that the tool will not

bounce around, uncontrolled. Pressing very hard on the

tool will not increase the efficiency.

Drilling in wood or metal

1

010157

Use the optional drill chuck assembly. When installing it,

refer to "Installing or removing drill bit" described on the

previous page.

Set the action mode changing knob to the

symbol.

You can drill up to 13 mm diameter in metal and up to 32

mm diameter in wood.

CAUTION:

• Never use "rotation with hammering" when the drill

chuck assembly is installed on the tool. The drill

chuck assembly may be damaged.

Also, the drill chuck will come off when reversing

the tool.

• Pressing excessively on the tool will not speed up

the drilling. In fact, this excessive pressure will only

serve to damage the tip of your bit, decrease the

tool performance and shorten the service life of the

tool.

• There is a tremendous twisting force exerted on the

tool/bit at the time of hole breakthrough. Hold the

tool firmly and exert care when the bit begins to

break through the workpiece.

• A stuck bit can be removed simply by setting the

reversing switch to reverse rotation in order to back

out. However, the tool may back out abruptly if you

do not hold it firmly.

1. Drill chuck

assembly

1. Blow-out bulb