5

Align the hole in the side of the socket with the detent pin

on the anvil and push it onto the anvil of the tool until it

locks into place. Tap it lightly if required.

To remove the socket, simply pull it off.

For tool with firm fit detent pin

1

2

3

4

2

4

007324

To install the socket, align the hole in the side of the

socket with the detent pin on the anvil.

Push the socket onto the anvil until it snaps into place.

Tap it lightly if required.

To remove the socket, depress the detent pin through the

hole in the socket and pull the socket off the anvil.

OPERATION

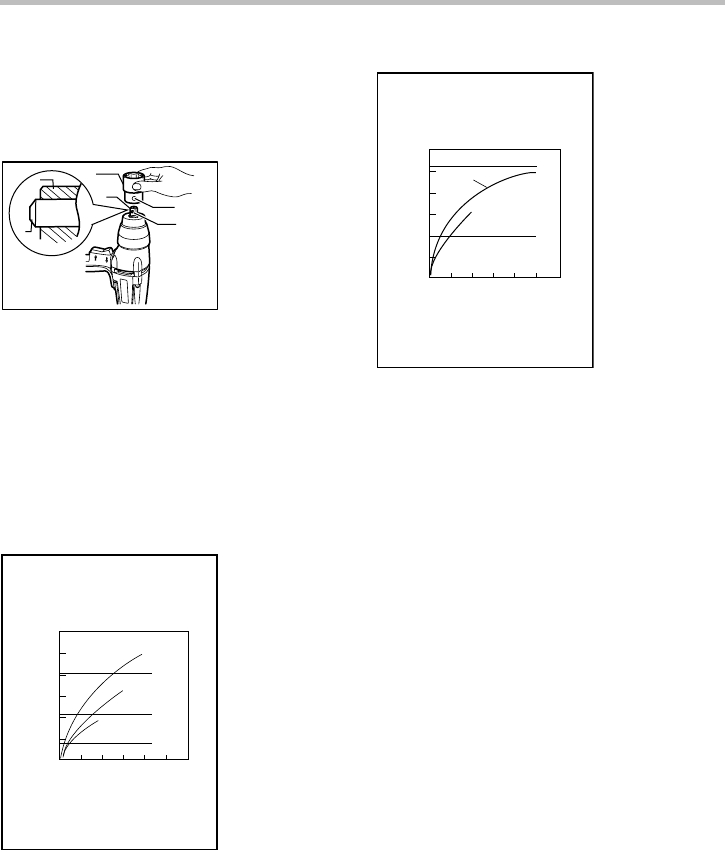

The proper fastening torque may differ depending upon

the kind or size of the bolt, the material of the workpiece

to be fastened, etc. The relation between fastening

torque and fastening time is shown in the figures.

0

0.5 1

1.5

2

2.5

50

100

150

200

250

300

Standard bolt

Fastening torque (N m)

Fastening time (S)

.

M12X80

(3/4"X3-1/8")

(5/8"X3-1/8")

(1/2"X3-1/8")

3

M16X80

M20X80

004009

0

1234

5

50

100

150

200

250

300

M16

M16(F10T)

High tensile bolt

Fastening torque (N m)

Fastening time (S)

(5/8")

(5/8")

(1/2"X3-1/8")

(1/2")

.

M12X80

M12

6

004010

Hold the tool firmly and place the socket over the bolt or

nut. Turn the tool on and fasten for the proper fastening

time.

NOTE:

• When fastening screw M12 (1/2") or smaller,

carefully adjust pressure on the switch so that the

screw is not damaged.

• Hold the tool pointed straight at the bolt or nut

without applying excessive pressure on the tool.

• If you fasten the bolt for a time longer than shown in

the figures, the bolt or the socket may be

overstressed, damaged, etc. Before starting your

job, always perform a test operation to determine

the proper fastening time for your bolt. Especially

for the bolt over than M12 (1/2"), perform the above

test operation to prevent the trouble on socket or

bolt, etc.

The fastening torque is affected by a wide variety of

factors including the following. After fastening, always

check the torque with a torque wrench.

1. Voltage

Voltage drop will cause a reduction in the fastening

torque.

2. Socket

• Failure to use the correct size socket will cause

a reduction in the fastening torque.

• A worn socket (wear on the hex end or square

end) will cause a reduction in the fastening

torque.

3. Bolt

• Even though the torque coefficient and the

class of bolt are the same, the proper fastening

torque will differ according to the diameter of

bolt.

• Even though the diameters of bolts are the

same, the proper fastening torque will differ

1. Socket

2. Anvil

3. Hole

4. Detent pin