14 |

Work safely

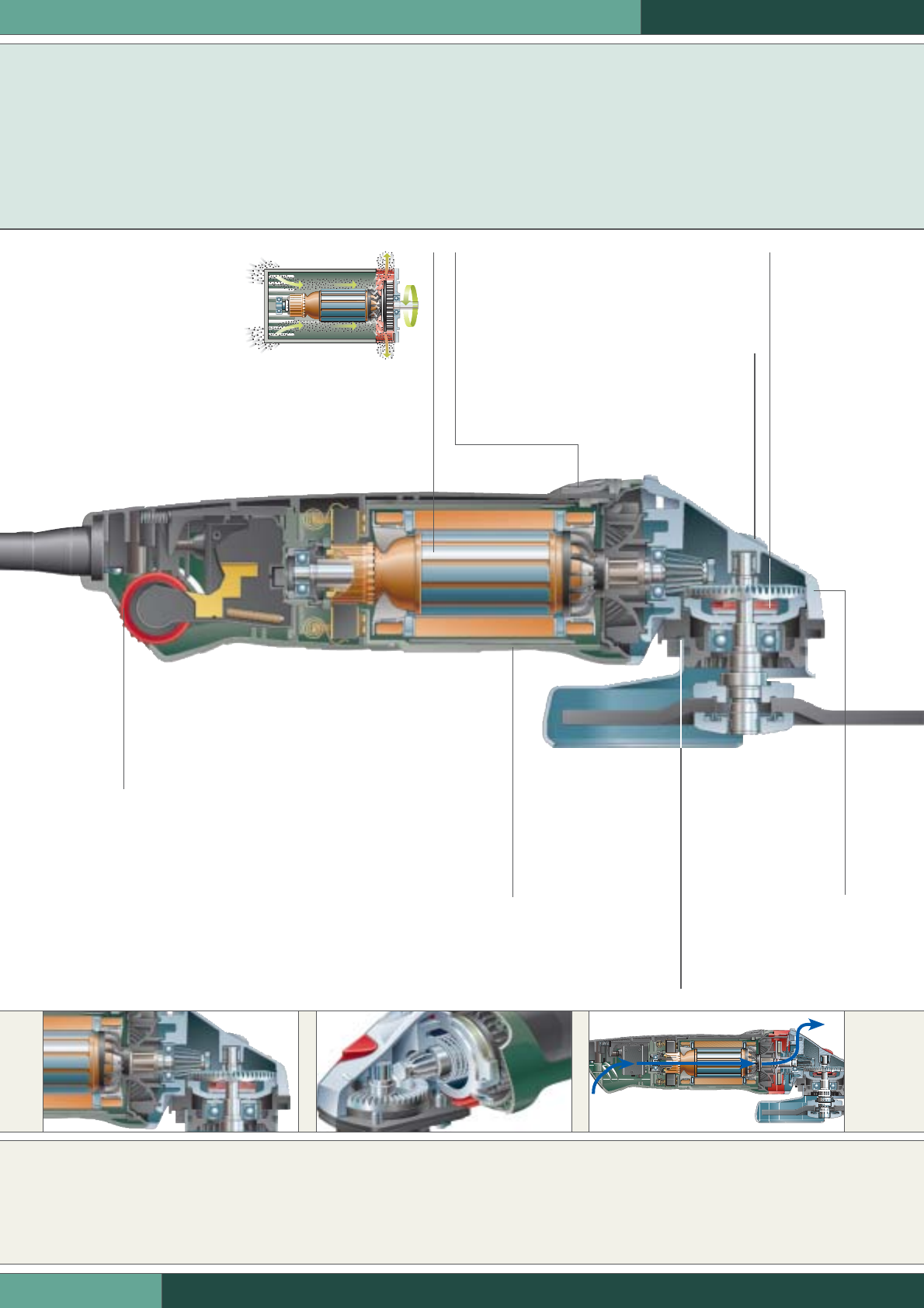

The hardwearing Metabo disc brake brings the grinding disc to a stop

within three seconds of switching off the angle grinder.

An important advantage for protecting the user (WB 11-125 Quick

and WB 11-150 Quick only).

Optimum cooling

An improved sonically balanced fan coupled

with better venting and more efficient internal

ducting channels have resulted in a 10-15%

increase* in air flow over the motor. As a

result, these new grinders can work harder

for longer; performance and durability are

increased. (* dependant on model)

Ergonomic design

The ergonomic housing de-

sign and its pronounced ne-

cking provides a secure grip

for every application.

Metabo S-automatic

torque limiting clutch

Prevents sudden reverse kick back if a

disc or bit should jam in the work piece

- protecting machine and user.

Metabo „Quick“ System

Simple, fast disc

exchange without tools.

Thumbwheel for speed selection*

In order to provide greater flexibly

for different applications, the speed

can be changed to accommodate

the material being machined.

(* dependant on model)

Disc guard with

adjustment option

without tools

Protection against sparks.

Can be adjusted individual-

ly, easily and quickly for all

types of jobs.

Die cast aluminium

gear housing

Metal gear housings

ensure optimum integral

machine strength and

maximum heat dissipa-

tion which aids motor

cooling and

prolongs service life.

Marathon motor with coil guard

Expertly machined and balanced motors use high grade coppers

and steels, increase efficiency and provide optimum performance. Thick

resin coatings on the armature and field coil protect the motor from harmful

debris, increasing service life. The large fan ensures optimal cooling for

maximum efficiency, allowing for increased

torque capability.

Encapsulated

switch

It eliminates

electrical spark-

overs caused

by

the accu-

mulation of

metallic dust.

ANGLE GRINDERS

TIME TO GET TOUGH.

Grinders have to work in the most extreme environ-

ments of any powertool. Motors have to cope with high

loading, extreme heat and in many cases burning hot

swarf and carbon particles for long periods of time. This

is why Metabo have developed their infamous Marathon

motor with special resin coatings and armature protec-

tion grids. Coupled with sonically balanced high volume

flow rate fans, safety clutches and high quality accesso-

ries users can enjoy up to five times longer life than that

of a standard motor. Metabo – No Compromise.