3 Technical Data

BKH 400/3,1 WNB BKH 450/5,5 DNB

Table size 1000x660 mm 1000x660 mm

Overall height 850 mm 850 mm

Cutting height 127 mm 140 mm

Motor speed 2800 min

-1

2800 min

-1

Cutting speed 58,5 m/s 66 m/s

Vertical adjustment 0-127 mm 20 - 140 mm

Motor power 3100 W 5500 W

Operating voltage 1~230 V 3~400 V

Supply frequency 50 Hz 50 Hz

Protection by fuse 1x16 A 3x16 A

Emissionswert

Emission value while operating DIN 45635

Idling speed 83,8 dB(A) 88,9 dB(A)

Operating 91,3 dB(A) 92,9 dB(A)

Noise emission value

Iding speed 94,7 98,1

Operating 99,0 101,1

Weight 90 kg 90 kg

Stock-No. 010 400 3109 010 450 5503

4 Standard delivery

Circular saw blade 400 x 2,2 or 450 x 2,5 , chrome steel

Riving Knife DIN 38820 , size 50 x 3

Sawblad guard

Ripping fence

Mitre fence

Lifting eyes

Push stick

Tools for mounting saw blade and riving knife

Manual / Operation instructions

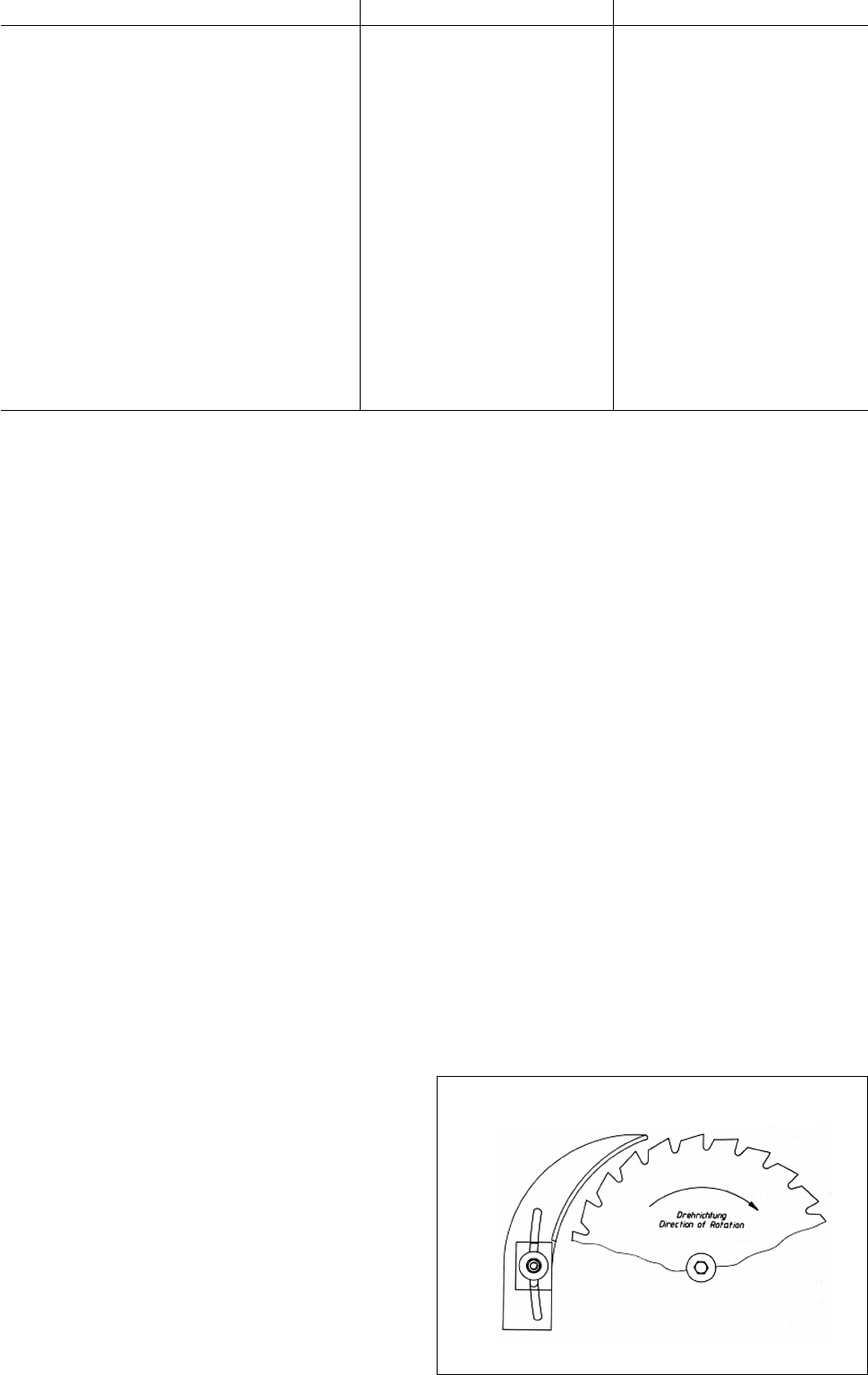

- On saws with 230 V single-phase current the direction

of rotation does not have to be checked or changed.

- On saws with 400 V three-phase-current the direction

of rotation has to be checked through switching on the

saw briefly (max. 1 sec). To change the direction of

rotation, the two connecting pins can be turned from

the outside. In order to do this you have to pull the plug

from the socket and press both pins inside with a 6 mm

blade screw driver, and then turn them.

- The switch can be protected from unauthorized use

with a padlock.

6.3 Change of the Direction of Rotation of the saw blade

6.2 Mains supply

- A three-wire cable connection socket with an earthing contact is needed for the mains supply according to VDE 0100 for

the model BKH 400/3,1 .

- For model BKH 450/5,5 respectively a five-wire cable connection with a CEE plug-in device according to VDE 0100 is

needed.

- Only a rubber cable H 07 RN-F 3 x 1,5 or 5 x 1,5 may be used as an extension cord.

- The plug to which the machine is connected must match the VDE regulation 0100.

- If used on a construction site, the VDE regulation 0100 part 704 must be obeyed.

6 Putting into operation

6.1 Erection of the Machine

The machine must be firmly mounted at a flat and stable place. Tripping should be avoided.

5 Assembly

For transport purposes the saw blade guard is fixed under the table and has to be assembled.