GB

1 User Responsibility

This tool will perform in conformity with the description contained in the instructions provided. This tool must be

checked periodically. Defective equipment (including service leads) should not be used. Parts that are broken,

missing, plainly worn, distorted or contaminated, should be replaced immediately. Should such repair or replace-

ment become necessary, it is recommended that such repairs are carried out by qualified persons approved by

metabo or its representatives.

This tool or any of its parts should not be altered or changed from standard specifications. The user of this tool

shall have the sole responsibility for any malfunction which results from improper use or unauthorized modification

from standard specifications, faulty maintenance, damage or improper repair by anyone other than qualified

person approved by metabo or its representatives.

2 Safety Precautions

● Use only chisels approved for use with pneumatic chisel hammers

● Always wear appropriate apparel (safety glasses, gloves, helmet)

● Always disconnect from compressed air supply before servicing

● The work place sound power level can exceed 85 dBA. In this case noise control measures for the operator

are required.

3 Preparing for Operation

Ensure compressed air is dry and air lines do not contain condensate. Set to desired impact power by adjusting

the regulator screw. Use only chisels and bits in good operating condition and suitable for the job.

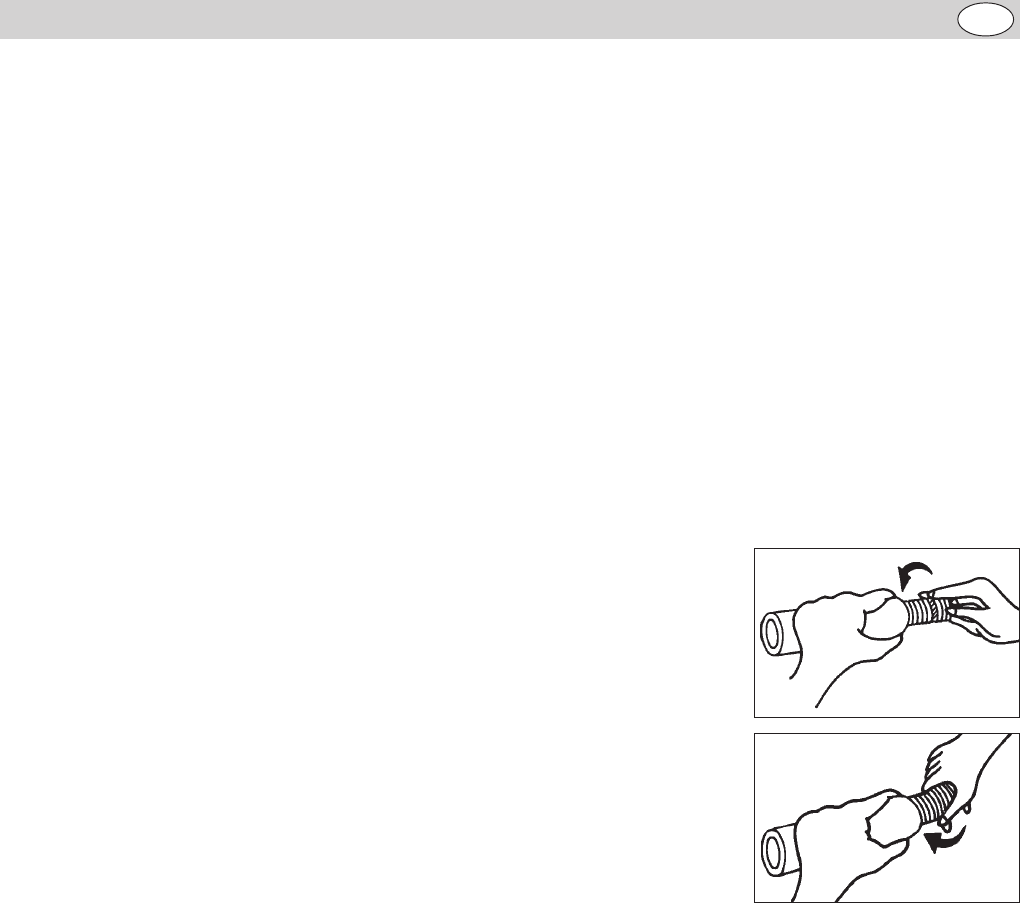

Place chisel in spring retainer, hold retainer at front end and screw onto

cylinder.

To change the chisel hold rear end of spring retainer and unscrew from

cylinder.

Note: To prevent built-up of dust or foreign matter inside the chuck, lubricate with a few drops of machine oil every

two working hours.

4 Air Supply

The operating pressure for this air tool should not exceed 6 bar/87 psi. A higher operating pressure, as well as

soiled air shorten the life of the air tool and may cause dangerous situations. Condensate (condensed water) in

the air lines damages an air tool. Drain condensate from pressure vessel daily. Clean filter or screen in air inlet of

the air tool at least once a week. It is recommended to install a pressure regulator with integrated water trap and

an oiler in the supply line near the tool.

5 Maintenance

Give a few drops of pneumatic oil into the air inlet daily.

6 Specifications

MHS 315 S MHS 450 S

Operating pressure 6 bar / 87 psi 6 bar /87 psi

Air consumption 156 l/min 430 l/min

Air inlet thread 1/4" 1/4"

Recommended hose size 9 mm / 3/8" i.d. 9 mm / 3/8" i.d.

Weight 1.2 kg 2.0 kg

Blows per minute 3000 2900-3300

Piston diameter 19 mm 19 mm

Piston stroke 67 mm 67 mm

Vibration 8.2 m/s

2

8.2 m/s

2

Sound power level LP

A

at the operator's

ear based on DIN 45 635 ff 88 dB 88 dB

The noise emission of this chisel hammer has been measured according to DIN 45 635 ff; 84/537/EEC for

chisel hammers.