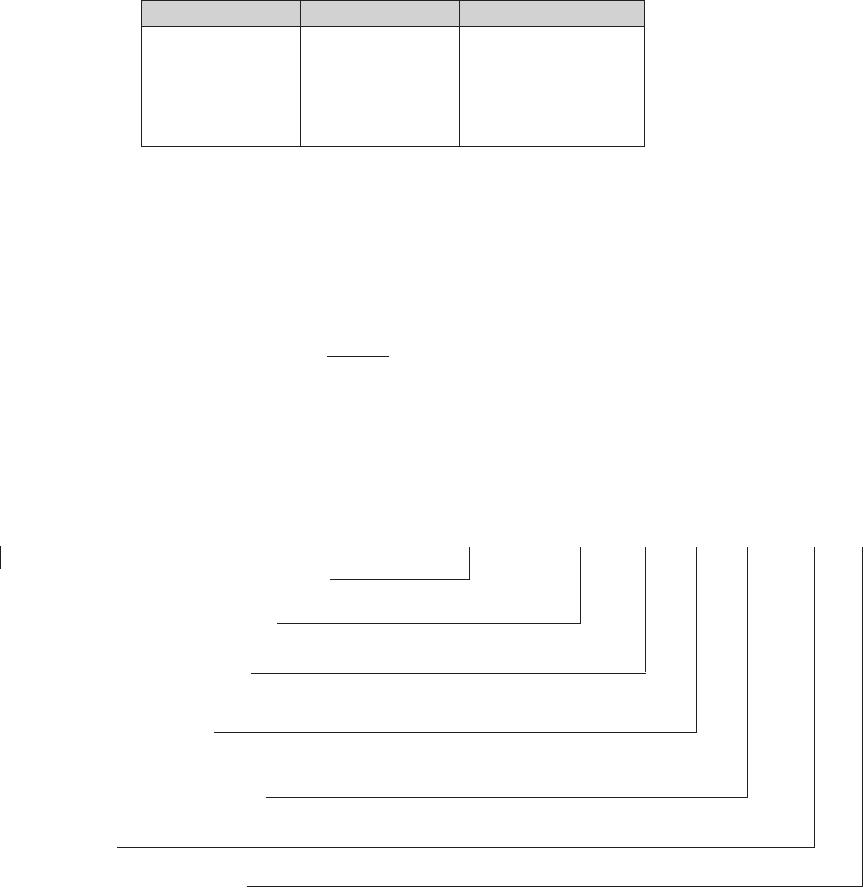

Example:

Stick electrode DIN 913 - E 43 3 2 AR 7

Type of electrode Number of DIN standard

Code for manual electric arc welding

Code number for tensile strength,

yield point and elongation

Code number for impact

engergy of 28 Joule minimum

Code number for increased impact

energy of 47 Joule minimum

Code for coating

Code number for electrode class

3.1 Care of Stick Electrodes and their correct Use

3.1.1Coding of Stick Electrodes according to DIN 1913

In order to achieve a good weld the electrode has to be dry, thus storing in a dry place is essential- Should

electrodes have become moist, dry in an oven at between 200° C to 300° C for 30 minutes.

Basic coated low-hydrogen type electrodes always require pre-drying at 200° C to 300° C for 3 hours as atomic

hydrogen causes weld flaws.

The designation of welding electrodes is standardized by DIN 1913. The designation is stipulated by the

electrode manufacturers in accordance with the standard and checked by an inspection body. It is printed on

the electrode packet.

14

Select the correct welding current as shown below:

Current (A) Electrode Ø Material Thickness

25 - 50 1.0 - 2.0 mm 1.0 - 2.0 mm

50 - 100 2.0 - 2.5 mm 2.0 - 4.0 mm

100 - 140 2.5 - 3.25 mm 4.0 - 8.0 mm

140 - 220 3.25 - 5.0 mm 8.0 - 12.0 mm

220 - 300 5.0 - 6.0 mm 12.0 - 20.0 mm

In principle do not use too thick an electrode. As a general rule calculate 40 amps welding current per 1 mm of

electrode diameter. Depending on electrode type, material thickness and weld position this calculated value may

have to be adjusted to plus or minus. All machines work well with thin plate from 1.0 mm thickness.

3 General Information for Welding Transformer/Rectifier Operators

Dust, dirt and metal chips will harm any welding machine. It is of particular importance that the air ventilation for

cooling is not obstructed.

A weld should join two work pieces as if they were made from a single piece. Prior to the welding the joints must

be cleaned and dirt, rust, grease and paint removed. Also slag from previous welds must be completely removed.

Attach earth clamp firmly to work piece, assuring good metal to metal contact. Check that all cables and

connectors are in proper operating condition to ensure proper current conduction.

Place electrode with the uncoated end into one of the electrode holder's notches. Each welding machine is

supplied complete with an accessory kit, comprising the welding cables, a welding visor and a slag hammer.

When removing slag it is recommended to protect the eyes by suitable means (goggles) from injury by sharp and

hot slag. The welding visor's dark glass plate protects the eye against ultra-violet and infrared rays. The clear

glass plate protects the dark plate against spatters and damage. The dark protective glass is available in different

shades for different types of electrodes and to suit different eye sensivity. Normally for electrodes from 1.5 mm

to 4 mm Ø protective glasses of shade DIN 9 are used, for electrode over 4 mm Ø shade DIN 10.

Attach earth clamp to the workpiece, close to the weld seam and on bare metal for good conduction.

Place stick electrode into the electrode holder.

With the handwheel select the desired welding current.

If there is not power outlet near the work area an extension cable is required. The cable's lead cross section must be

at least 2.5 mm

2

. Uncoil extension cable fully to prevent heatbuild-up by inductance. Inductance also conside-rably

reduces the welding current. Extension of the welding cables is also possible, but the cross section of the extension

cables must be larger than that of the cables supplied with the machine.

Every machine is protected against overloads by a thermo switch, which switches the power to the transformer off if it

becomes too hot. After a short cooling-down period the machine will switch back on automatically. Model SB 200 CT

is equipped with a fan for forced cooling, given better performance with a higher duty-cycle.