3

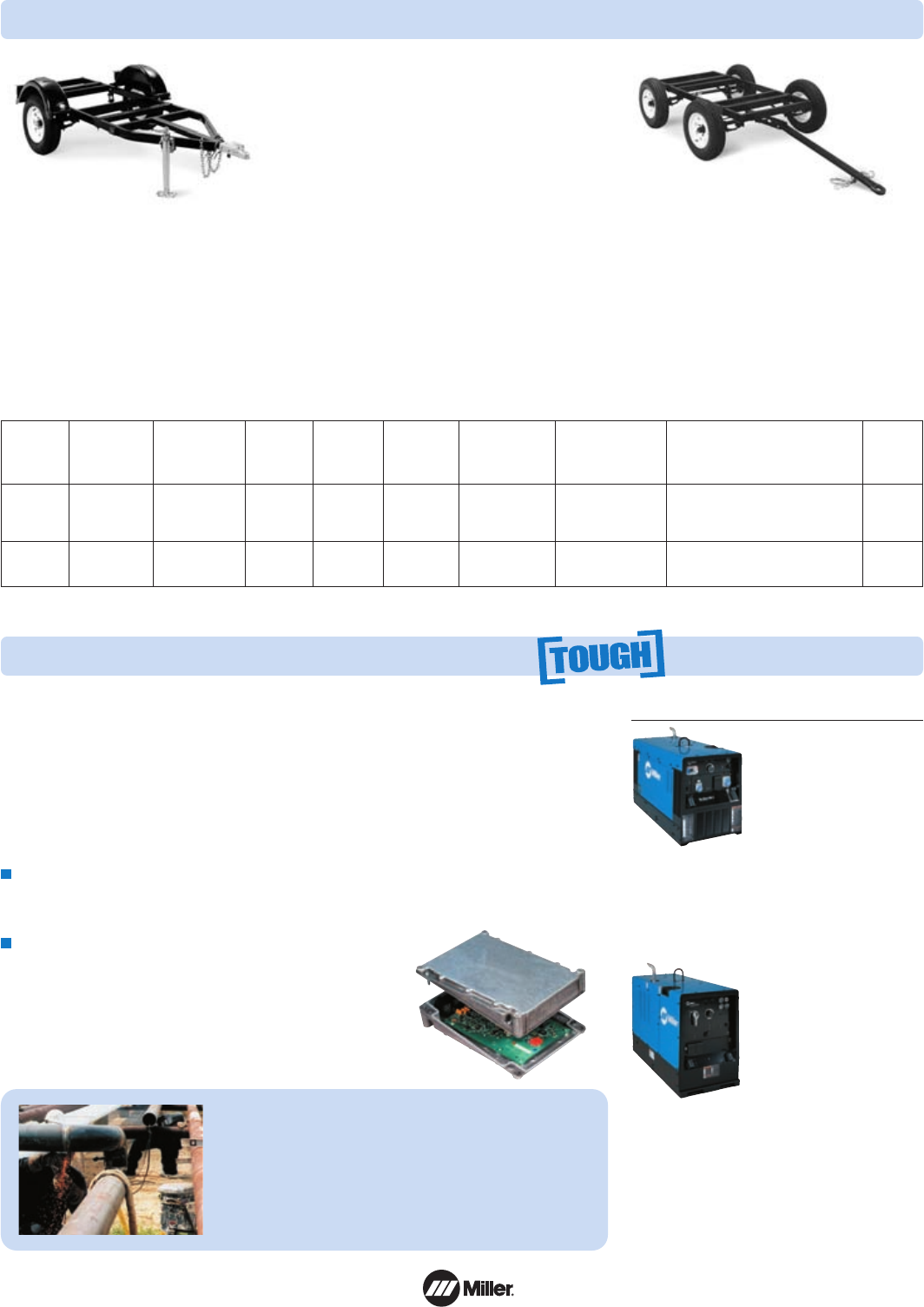

HWY-224 Trailer #043 805

A 1202 kg (2650 lb) capacity highway

trailer. Welded steel tubing frame, heavy-

duty axle with roller bearing hubs and

leaf-spring suspension. The HWY-224

comes with jack stand, 50 mm (2 in)

ball hitch, fenders and lights.

OFR-224 Trailer #043 802

A 1202 kg (2650 lb) capacity off road

trailer. Welded steel tubing frame, heavy-

duty axle with roller bearing hubs and

leaf spring suspension. The OFR-224

comes with jack stand and 50 mm (2 in)

ball hitch.

Lunette Eye 64 mm (2-1/2 in) #043 824

For use with both 224 trailers.

Cable Tree #043 826

Provides an area to conveniently wrap weld

cables and extension cords. Works on all

224 and 430 trailers.

4 West Four-Wheel Steerable Off-Road

Trailer #042 801

A heavy-duty 1166 kg (2570 lb) capacity

trailer designed for use in mines, quarries,

and other rough terrain. Has narrow 6.7 m

(22 ft) turning radius. Includes 76 mm (3 in)

lunette eye, universal hitch and safety chains.

Note: Trailers are shipped unassembled.

Trailers and Hitches

Trailer Specifications (Subject to change without notice.)

Net

Payload

1202 kg

(2650 lb)

1166 kg

(2570 lb)

Gross

Vehicle

Weight Rating

1343 kg

(2960 lb)

1361 kg

(3000 lb)

Gross Axle

Weight

Rating

1588 kg

(3500 lb)

907 kg/axle

(2000 lb/axle)

Model

HWY-224

OFR-224

4 West

Height

of Bed

18-1/2 in

(470 mm)

540 mm

(21-1/4 in)

Road

Clearance

191 mm

(7-1/2 in)

203 mm

(8 in)

Net

Weight

161 kg

(355 lb)

1950 kg

(430 lb)

Track

(Center to

center of tires)

1321 mm

(52 in)

1403 mm

(55-1/4 in)

Standard Tires

(Standard rating

or P-size rating)

B78-13C

B78-13

Dimensions

Length:3112 mm (122-1/2in)

Width: HWY– 1549 mm (61 in)*

OFR–1486 mm (58-1/2 in)

Length:2311 mm (91 in)**

Width: 1556 mm (61-1/4 in)

*

Width at outside of fenders.

**

Does not include tongue.

Every component in a Miller industrial engine drive is engineered and built to assure

ultimate reliability in the most punishing conditions. And they are rigorously tested to

the toughest real-world conditions to keep working in a tough world.

Ultimate Circuit Board Protection

No matter how well it’s built, any machine can fail if its critical circuit boards are

compromised. Miller makes two types of industrial engine drives, both of which ensure

that no critical circuit boards are left vulnerable.

“CC” Stick and TIG Models — Miller’s robust, efficient constant current (CC) industrial

engine drives for Stick and TIG welding are designed with no circuit boards that are critical

to the machine’s operation. That means no boards can shut down the machine if they fail.

“CC/CV” Multiprocess Models — Miller’s Multiprocess

PRO 300 and Big Blue

®

models of industrial engine drives

include circuit boards for superior arc control and welding

versatility. These boards are protected by the Vault, a

hermetically-sealed aluminum case that is impenetrable to

dust, salt, and moisture.

Similar models to consider:

Big Blue

®

400 X

See Lit. No. EDX/10.1

For the professional

heavy-duty construction

contractor, pipeline, rental

company or anyone wanting

a fuel-efficient low-speed diesel-powered

multiprocess welder/generator with precise arc

control. The heavy-duty, compact case easily

fits sideways in a standard pickup bed. This

model provides the quietest operation of Miller’s

engine-drive machines.

Big Blue

®

500 X and

600 X

See Lit. No. EDX/10.11

For fleet owners, heavy-duty

construction contractors,

and rental companies who

want a low-speed diesel-

powered welder/generator with rugged reliability

and proven performance. Ideal for really tough

jobs that may be using larger electrodes for Stick

welding or Carbon Arc gouging. Available in either

a Stick/TIG CC only model, or a more versatile

CC/CV multiprocess model. Easy to maintain and

always ready to weld no matter what the job or

conditions demand.

What Makes Miller Industrial Engine Drives So ?

“Other machines would cut out when we gouged too long

with them. With the Miller, I gouged hard all day in 98 degree

heat and never had a shutdown when we were running

3/8-in carbons.” When welding, “The Big Blue starts out

hot, where I want it, and stays steady on its heat all day.”

— Welder Tommy Langley, Fluor Daniel/Chevron Oil Refinery