OM-491 Page 39Return To Table Of Contents

9-5. Adjusting Engine Speed

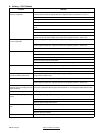

802 168-C / 802 229-A / Ref. 202 705

Y Stop engine and let cool.

Engine speed is factory set and

should not require adjustment. Af-

ter tuning engine, check engine

speed with tachometer or frequen-

cy meter. See table for proper no

load speed. If necessary, adjust

speed as follows:

Start engine and run until warm.

On CC Models, place Stick/TIG

switch in Stick position.

On CC/CV models, turn Process/

Contactor switch to Stick − Elec-

trode Hot position.

Standard Models

1 Adjustment Screw

2 Lock Nut

Loosen nuts. Turn screws out sev-

eral turns.

3 Speed Lever

Start engine and move lever until

engine runs at weld/power speed.

Tighten adjustment screws and

lock nuts.

. Do not set engine speed higher

than specified.

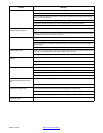

Models With Automatic Idle

(Optional)

Idle Speed Adjustment

4 Throttle Rod/Plunger

5 Locknut

Loosen locknut. Place Engine Con-

trol switch in Run/Idle position.

Turn throttle rod and plunger until

engine runs at idle speed. Tighten

locknut.

. Be sure solenoid plunger pulls

all the way in (“bottoms”) when

energized.

Weld/Power Speed Adjustment

6 Engine Weld/Power Speed

Adjustment Screw

7 Locknut

Place Engine Control switch in Run

position.

Loosen locknut. Turn screw until

engine runs at weld/power speed.

Tighten locknut.

. Do not set engine speed higher

than specified.

Y Stop engine.

Close door.

Tools Needed:

5/16 in

1

2

12

3

1850 rpm

(61.6 Hz)

1500 rpm

(50 Hz)

Weld/Power

Idle

Engine Speed

(No Load)

Standard Models

Models With Automatic Idle (Optional)

54

6

7