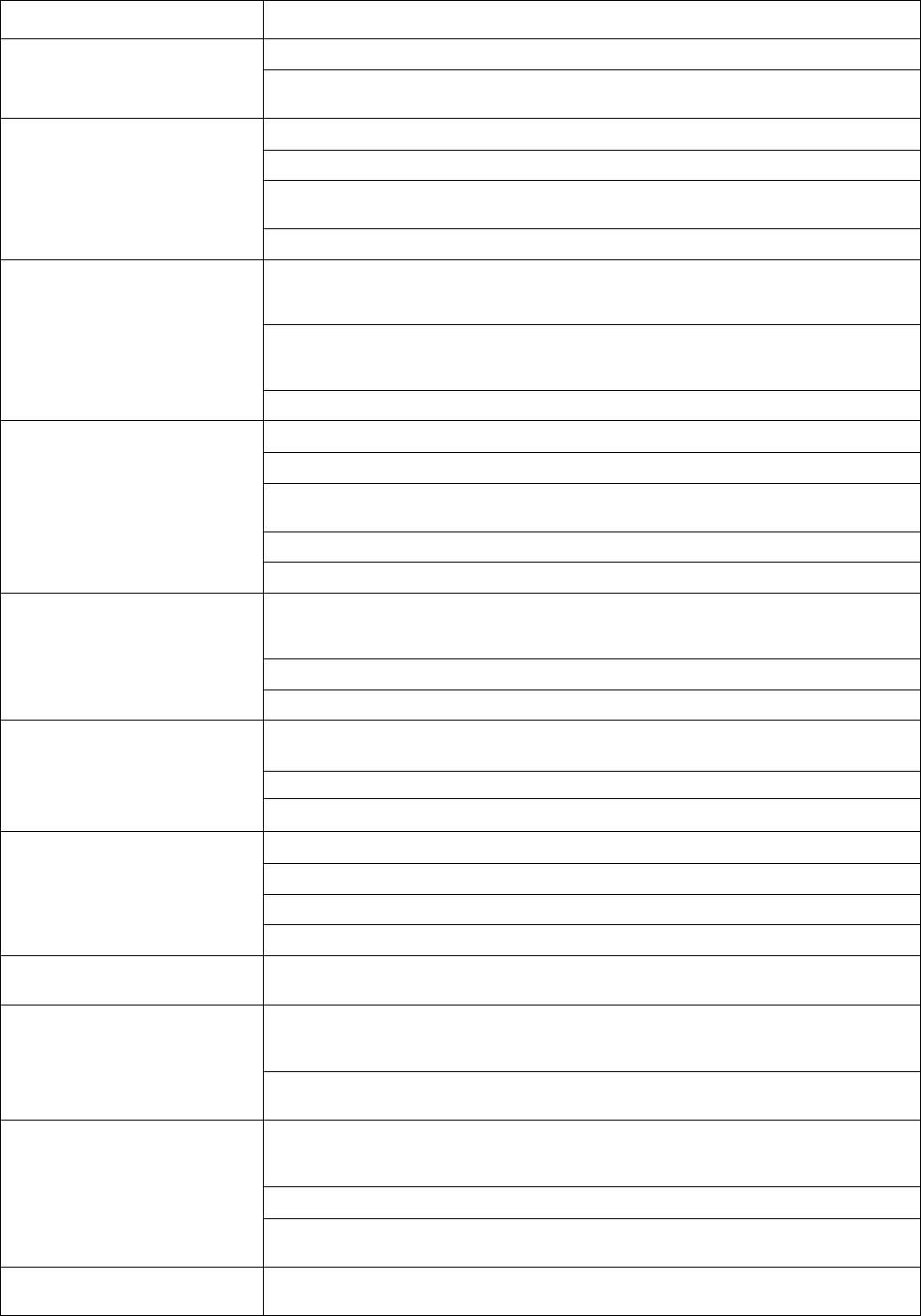

OM-4429 Page 50

Trouble Remedy

Check engine wiring harness plug connections.

Have Factory Authorized Service Agent check control relay CR1, diode/capacitor board D8/C8, and En-

gine Control switch S1.

Engine cranks but does not start. Check fuel level.

Check battery and replace if necessary. Check engine charging system according to engine manual.

Have Factory Authorized Service Agent check engine wiring harness, time delay relay TD1, control

relay CR5, fuel pump, fuel solenoid FS1, and diode/capacitor board D10/C10.

Air in fuel system. See engine manual.

Engine starts, but stops after 30

seconds.

Check oil, and coolant levels. Automatic shutdown system stops engine if oil pressure is too low or coolant

temperature is too high (see Section 5-7). Automatic shutdown system is inhibited for 30 seconds after

start-up.

Check engine speed. Overspeed shutdown automatically stops engine if speed is too high. Turn engine

off and restart to resume operation. If unit continues to overspeed and shut down, have unit checked by

a Factory Authorized Service Agent.

Have Factory Authorized Service Agent check time delay relay TD1, and control relay CR5.

Engine hard to start in cold weather. Use starting aid switch (see Section 6-1 or 7-1).

Keep battery in good condition. Store battery in warm area off cold surface.

Use fuel formulated for cold weather (diesel fuel can gel in cold weather). Contact local fuel supplier for

fuel information.

Use correct grade oil for cold weather (see Section 9-1).

Have Factory Authorized Service Agent check starting aid switch and glow plugs.

Engine suddenly stops. Check oil and coolant levels. Automatic shutdown system stops engine if oil pressure is too low or coolant

temperature is too high (see Section 5-7). Automatic shutdown system is inhibited for 30 seconds after

start-up.

See engine manual.

Have Factory Authorized Service Agent check engine speed sensor.

Engine slowly stopped and cannot be

restarted.

Check fuel level.

Check engine air and fuel filters (see Sections 9-3 and 9-6).

See engine manual.

Battery discharges between uses. Turn Engine Control switch off when unit is not running.

Clean top of battery with baking soda and water solution; rinse with clear water.

Recharge or replace battery if necessary.

Periodically recharge battery (approximately every 3 months).

Engine does not run at weld/power

speed.

Have Factory Authorized Service Agent check engine controller, throttle actuator TS1, and speed sensor.

Engine idles, but does not come up to

weld speed (models with idle option

only).

Check for obstructed throttle actuator TS1.

Have Factory Authorized Service Agent check idle module PC7, current transformer CT1, throttle actua-

tor TS1, and engine controller.

Engine does not run at idle speed

(models with idle option only).

CC models: place Stick/TIG Selection switch in Stick position.

CC/CV models: place Process/Contactor switch in any position but Remote On/Off Switch Required-

TIG.

Check for obstructed throttle actuator.

Have Factory Authorized Service Agent check idle module PC7, control relay CR6, throttle actuator TS1,

speed sensor, and engine controller.

Engine uses oil during run-in period;

wetstacking occurs.

Dry engine according to run-in procedure (see Section 11).