OM-1600 Page 9

SECTION 5 − SELECTING AND PREPARING TUNGSTEN

ELECTRODE FOR DC OR AC WELDING

ac/dc_gtaw 2/2004

Y Whenever possible and practical, use DC weld output instead of AC weld output.

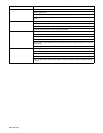

5-1. Selecting Tungsten Electrode (Wear Clean gloves To Prevent Contamination Of Tungsten)

Amperage Range - Gas Type♦ - Polarity

Electrode Diameter DC − Argon − Electrode

Negative/Straight Po-

larity

DC − Argon − Elec-

trode Positive/Rev-

erse Polarity

AC − Argon AC − Argon −

Balanced Wave

2% Ceria (Orange Band), 1.5% Lan-

thanum (Gray Band), Or 2% Thorium

(Red Band) Alloy Tungstens

.010” Up to 25 * Up to 20 Up to 15

.020” 15-40 * 15-35 5-20

.040” 25-85 * 20-80 20-60

1/16” 50-160 10-20 50-150 60-120

3/32” 135-235 15-30 130-250 100-180

1/8” 250-400 25-40 225-360 160-250

5/32” 400-500 40-55 300-450 200-320

3/16” 500-750 55-80 400-500 290-390

1/4” 750-1000 80-125 600-800 340-525

Pure Tungsten

(Green Band)

.010” Up to 15 * Up to 15 Up to 10

.020” 5-20 * 5-20 10-20

.040” 15-80 * 10-60 20-30

1/16” 70-150 10-20 50-100 30-80

3/32” 125-225 15-30 100-160 60-130

1/8” 225-360 25-40 150-210 100-180

5/32” 360-450 40-55 200-275 160-240

3/16” 450-720 55-80 250-350 190-300

1/4” 720-950 80-125 325-450 250-400

Zirconium Alloyed Tungsten (Brown

Band)

.010” * * Up to 20 Up to 15

.020” * * 15-35 5-20

.040” * * 20-80 20-60

1/16” * * 50-150 60-120

3/32” * * 130-250 100-180

1/8” * * 225-360 160-250

5/32” * * 300-450 200-320

3/16” * * 400-550 290-390

1/4” * * 600-800 340-525

♦Typical argon shielding gas flow rates are 15 to 35 cfh (cubic feet per hour). *Not Recommended.

Figures listed are a guide and are a composite of recommendations from American Welding Society (AWS) and electrode manufacturers.