OM-219 316 Page 12

SECTION 5 − INSTALLATION

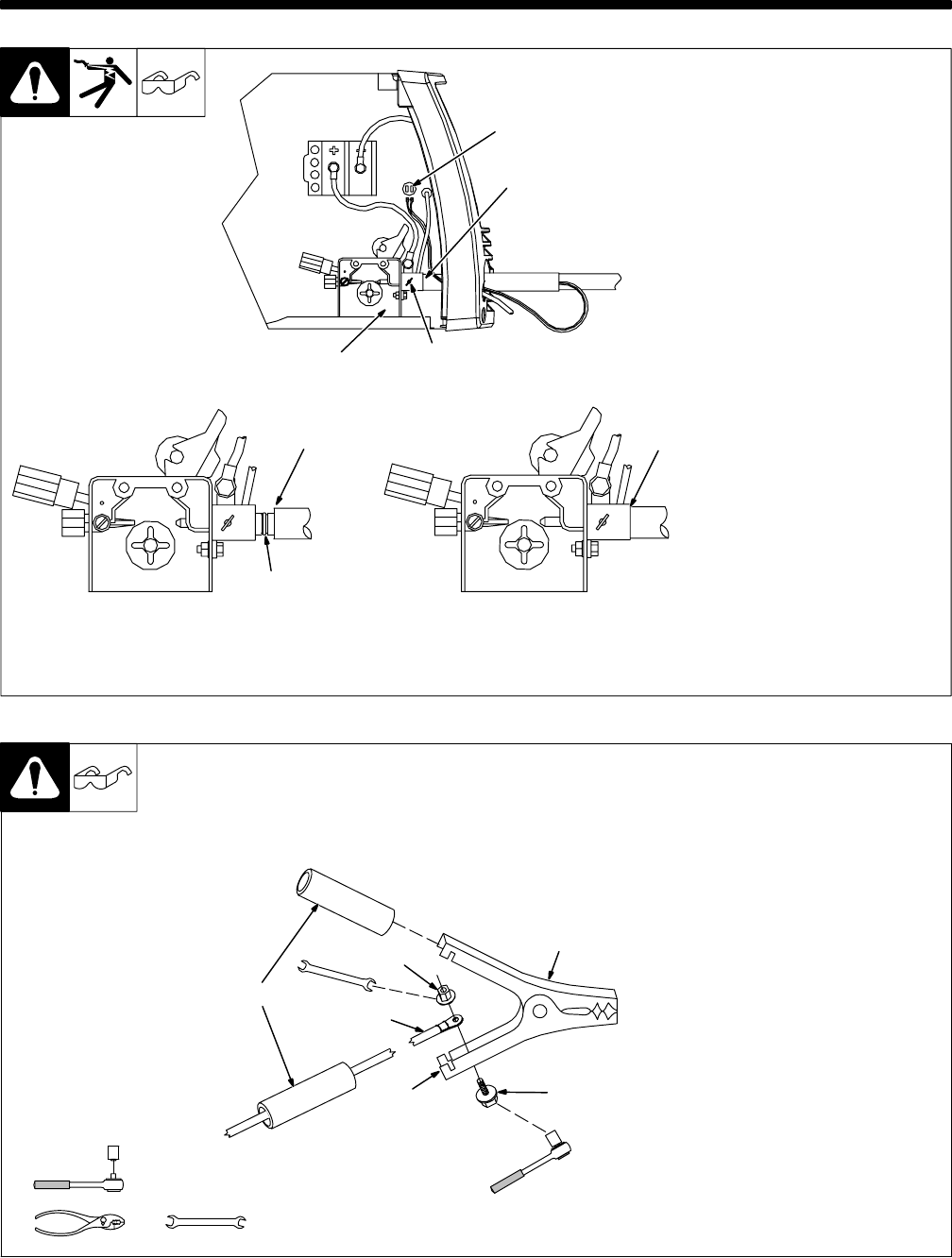

5-1. Installing Welding Gun

803 711-A

1 Drive Assembly

2 Gun Securing Thumbscrew

3 Gun End

Loosen thumbscrew. Insert end

through opening until it bottoms

against drive assembly. Tighten

thumbscrew.

Welding gun must be inserted

completely to prevent leakage of

shielding gas.

4 Gun Trigger Leads

Insert leads, one at a time, through

gun opening on front panel.

Connect female friction terminals to

matching male terminals in unit.

Polarity is not important.

Close door.

4

12

3

CorrectIncorrect

. Be sure that gun end is tight against drive assembly.

3

Gun Fully Seated

3

Gun Not Seated

Exposed O-rings

will cause shielding

gas leakage.

5-2. Installing Work Clamp

1 Nut

2 Work Cable From Unit

3 Work Clamp

4 Screw

5 Work Clamp Tabs

Bend tabs around work cable.

6 Insulating Sleeves

Slide one insulating sleeve over

work cable before connecting to

clamp.

Slide insulating sleeves over

handles.

802 456-A

. Connection hardware must be tightened with proper tools. Do not just

hand tighten hardware. A loose electrical connection will cause poor

weld performance and excessive heating of the work clamp.

1

2

3

4

5

Tools Needed:

7/16 in

6

7/16 in