OM-2225 Page 12

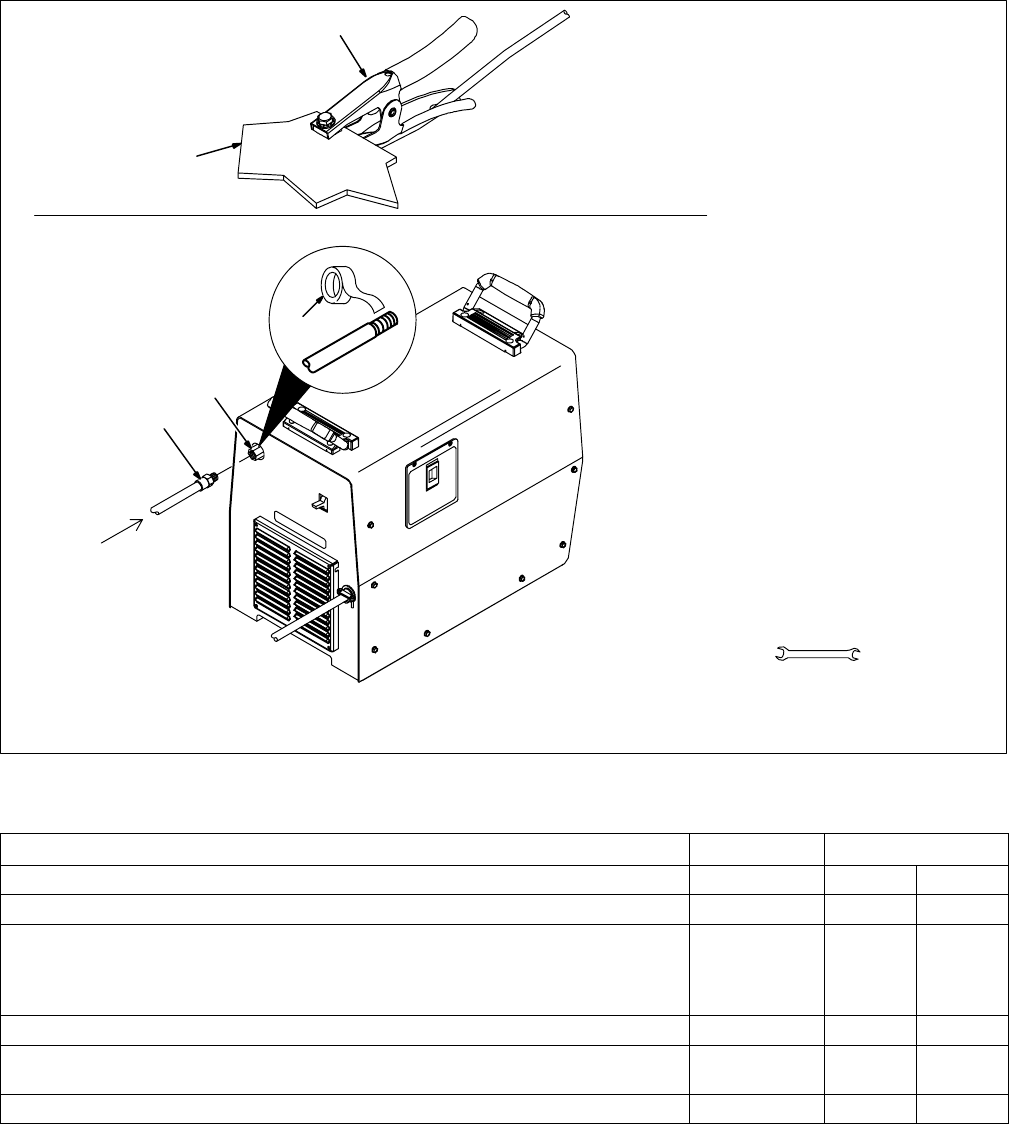

3-5. Connecting Work Clamp And Gas/Air Supply

Ref. 803 640-A / 802 201-B

1 Work Clamp

2 Workpiece

Connect work clamp to a clean,

paint-free location on workpiece, as

close to cutting area as possible.

. Use only clean, dry air supply

with 90 to 150 psi pressure.

Torch requires 80 psi pressure.

3 Gas/Air Inlet Opening

4 Hose

Use hose with an inside diameter of

at least 3/8 in. If hose is over 40 ft

(12.2 m) in length, use hose with 1/2

in inside diameter.

5 Teflon Tape

Obtain hose with 1/4 NPT right-

hand thread fitting. Wrap threads

with teflon tape (optional) or apply

pipe sealant, and install fitting in

opening. Route hose to gas/air

supply.

Adjust gas/air pressure according

to Section 4-2.

Tools Needed:

5/8, 1-1/8 in

From Gas/Air Supply

3

4

5

Rear of

Unit

1

2

3-6. Electrical Service Guide

Single Phase Three Phase

Input Voltage 230 230 460

Input Amperes At Rated Output 63 35 18

Max Recommended Standard Fuse Rating In Amperes

Circuit Breaker

1

, Time-Delay

2

70 40 20

Normal Operating 3 100 50 25

Min Input Conductor Size In AWG/Kcmil 8 10 14

Max Recommended Input Conductor Length In Feet (Meters)

71

(22)

97

(30)

152

(46)

Min Grounding Conductor Size In AWG/Kcmil 8 10 14

Reference: 1999 National Electrical Code (NEC)

1 Choose a circuit breaker with time-current curves comparable to a Time Delay Fuse.

2 “Time-Delay” fuses are UL class “RK5” .

3 “Normal Operating” (general purpose − no intentional delay) fuses are UL class “K5” (up to and including 60 amp), and UL class “H” ( 65 amp and

above).