OM-1592 Page 7

Figure 4-2. Sequence Of Plasma Arc Cutting (PAC)

HITTING TORCH ON A HARD SURFACE to remove

spatter can damage torch.

• Do not clean torch by hitting it against a hard surface.

• Hitting hard surfaces can damage torch parts and stop proper

operation.

TIP AND ELECTRODE WEAR BEYOND

RECOMMENDED VALUES or OPERATION

WITHOUT TIP OR ELECTRODE can damage torch.

• Inspect cup, tip, and electrode before cutting or whenever cutting

speed has been significantly reduced.

• Do not operate torch without a tip or electrode in place.

• Use correct standoff distance.

• Do not cut with gouging tip.

CAUTION

Check Torch

Tip, Electrode,

And Shield Cup

Install &

Connect

Equipment

Install

Gouging Tip

Check Gas/Air

Pressure

Set

Controls

Begin

Gouging

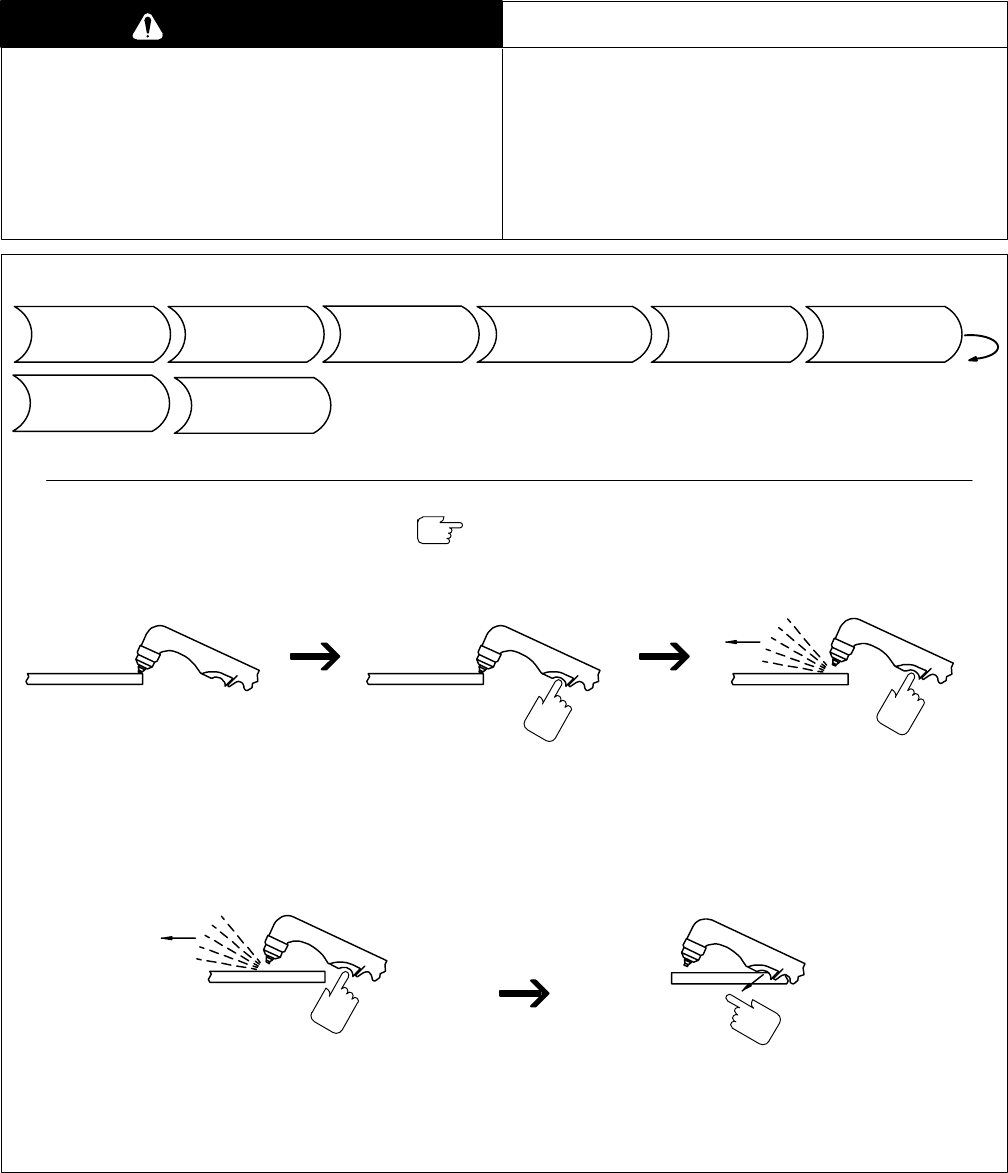

EXAMPLE Of Gouging Operation

ST-800 968

Use approx. 1/8 in (3 mm)

standoff distance at about

a 40° angle.

Establish arc length of 1/2 to 1-1/2 in

(13 - 38 mm), and slowly

start moving torch across metal.

Adjust torch speed, arc length and angle as needed.

Direct sparks away from torch. Do not gouge too

deeply in one pass; make repeated passes if needed.

Release trigger. Postflow continues for approx.

20 to 30 seconds. Gouging arc can be instantly

restarted during postflow by pressing trigger.

Turn On

Cutter

Put On Personal

Safety

Equipment

Press trigger. After 2 seconds of

preflow, pilot arc starts.

If cutting arc is not started within 5 seconds of pilot arc, pilot

arc will go out. There is a 20-second reset time before the pilot

arc can be restarted.

Figure 4-3. Sequence Of Plasma Arc Gouging (PAG)