OM-1215 Page 9

SECTION 2 – INSTALLATION

2-1. Specifications

Wire Diameter Range

Approximate

Wire Feed

Range

Cooling

Method

Maximum Spool

Size

Weld Circuit

Rating

Overall

Dimensions

Weight

.030 Thru .047 in

(0.8 Thru 1.2 mm)

Aluminum Wire

.030 Thru 047 in

(0.8 Thru 1.2 mm)

Hard Or Cored Wire

130 To 840 ipm

(4.1 To 20.4

mpm)

Air Cooled

4 in (102 mm)

Diameter

100 Volts, 200

Amperes, 60%

Duty Cycle

Using Argon

Shielding Gas

Length:

11-1/2 in (291 mm)

Width:

2-1/4 in (57 mm)

Height:

8 in (203 mm)

9.1 lb (4.1 kg)

Gun With Cable

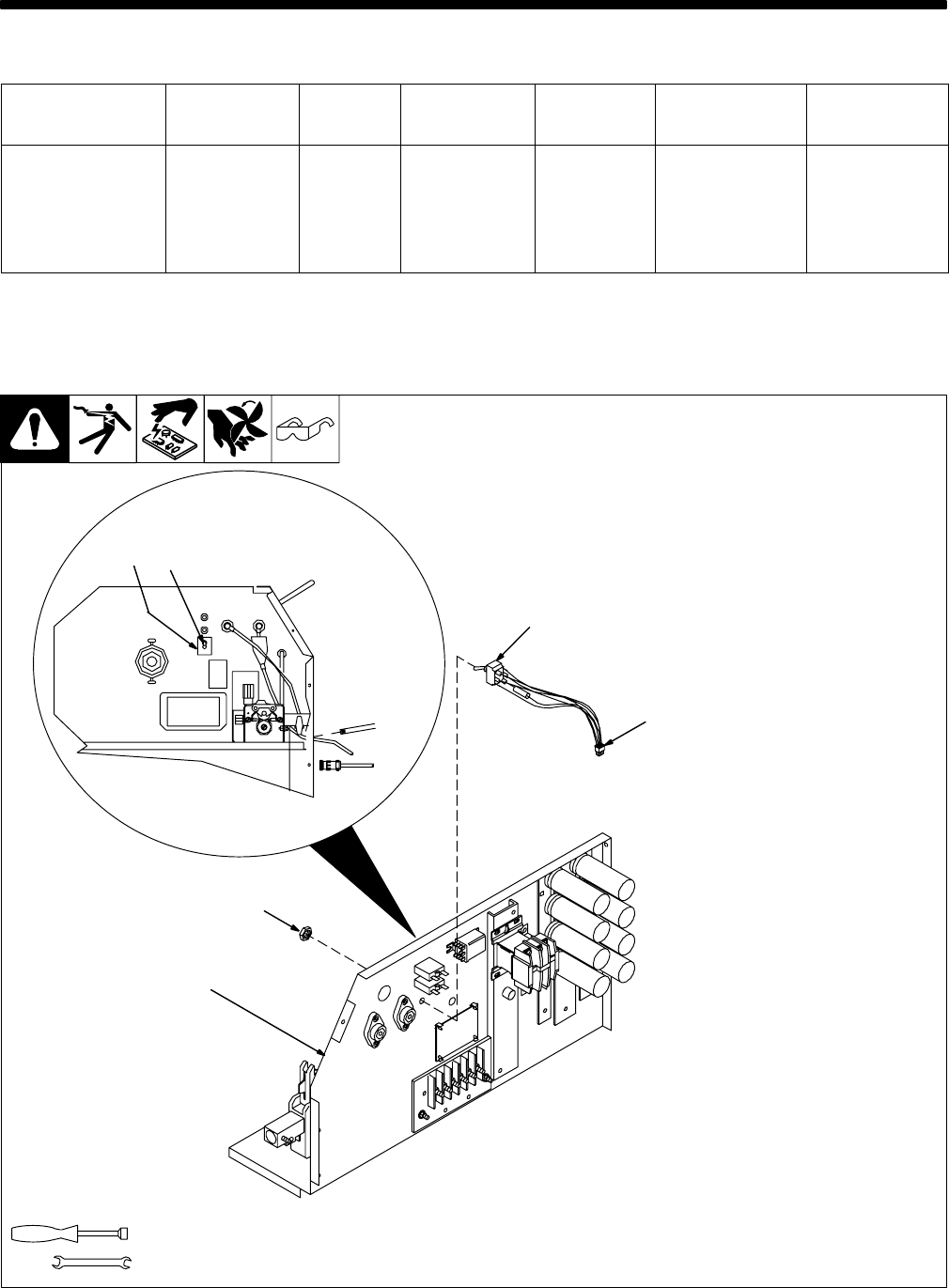

2-2. Installing Spoolgun Switch In Welding Power Source (If Connecting To Millermatic

185 Prior To Serial No. KH376829 Unit Requires Installation Of Field Kit 186871)

802 582

Tools Needed:

3/8 in

9/16 in

2

3

4

5

6

1

Y Turn Off unit, and disconnect

input power.

1 Welding Power Source Center

Baffle

2 Switch Location

Locate plastic plug in center panel.

Remove and discard plug.

3 Spoolgun Label

4 Spoolgun Switch

5 Jam Nut

Remove top jam nut from switch

(switch is equipped with two nuts, a

jam nut and a backing nut).

Insert switch shaft through center

panel. Switch should be positioned

so lead with resistor is facing down.

Secure switch to center panel with

jam nut. Tighten jam nut enough to

keep switch from rotating.

6 Spoolgun Switch Plug

Locate matching spoolgun recep-

tacle in wiring harness, and remove

jumper plug. Keep jumper plug in

case spoolgun switch is removed.

Connect spoolgun switch plug to

receptacle.

Reinstall wrapper.

Operation:

Place switch in On position for

spoolgun operation. Place switch in

Off position for wire feeder/MIG

(GMAW) gun operation.

When spoolgun switch is in On

position, spoolgun wire feed speed

is controlled by welding power

source Wire Speed control.