10 11

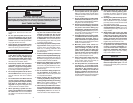

Fig. 7

To Drill

Fig. 8

To Drive Screws

2. To use the drilling only mode (Fig. 7),

rotate the hammer/drill selector collar

until the drill symbol appears in line

with the arrow. Then rotate the Torque

selector collar until the drill symbol

mmm

appears in line with the arrow.

The adjustable clutch ,when properly ad-

justed, will slip at a preset torque to prevent

driving the screw too deep into different

materials and to prevent damage to the

screw or tool.

For reverse (counterclockwise) rotation,

push in the control switch from the left side

of the tool (Fig. 10). Check direction of

rotation before use.

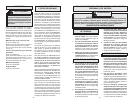

Using Control Switch (Fig. 9, 10, and 11)

The control switch may be set to three posi-

tions: forward, reverse and lock. Due to a

lockout mechanism, the control switch can

only be adjusted when the ON/OFF switch

is not depressed. Always allow the motor to

come to a complete stop before using the

control switch.

For forward (clockwise) rotation, push in the

control switch from the right side of the tool

(Fig. 9). Check the direction of rotation

before use.

Push in

for forward

Fig. 9

Fig. 10

Push in

for reverse

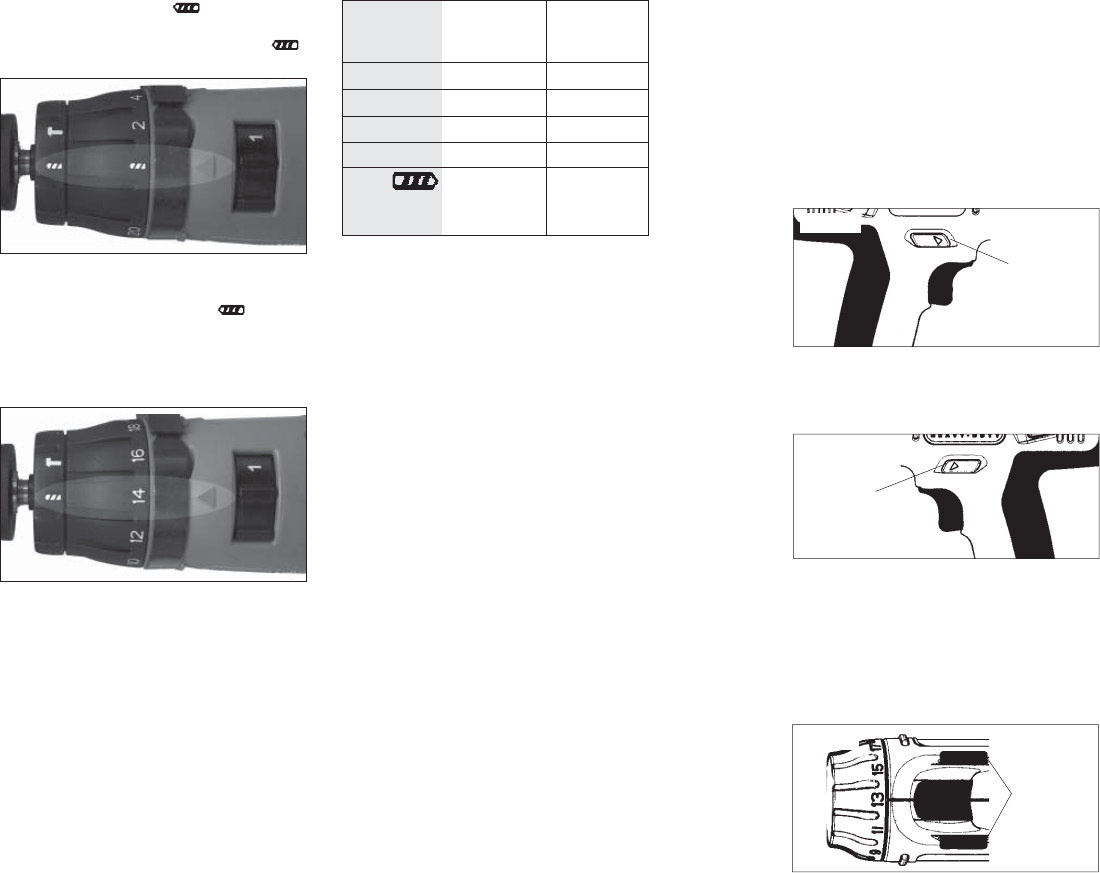

To lock the trigger, push the control switch

to the center position (Fig. 11). The trigger

will not work while the control switch is in

the center locked position. Always lock the

trigger or remove the battery pack before

performing maintenance, changing acces-

sories, storing the tool and any time the tool

is not in use.

3. To use the driving screws mode

(Fig. 8), rotate the hammer/drill selector

collar until the drill symbol appears

in line with the arrow. Then rotate the

torque selector collar until the desired

clutch setting appears in line with the

arrow.

Fig. 11

Push to

center

position to

lock trigger

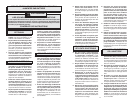

The torque specifications shown here are ap-

proximate values.

NOTE: Because the above settings are only

a guide, use a piece of scrap material to test

the different clutch positions before driving

screws into the workpiece.

Torque

selector

collar setting

1 - 5

6 - 10

11 - 15

16 - 20

Drill

Low

High

0 - 17 in. lbs.

21 - 38 in. lbs.

42 - 60 in. lbs.

65 - 85 in. lbs.

460 in. lbs.

160 in. lbs.

0615-20

& 0617-20

Torque

0 - 17 in. lbs.

21 - 38 in. lbs.

42 - 60 in. lbs.

65 - 85 in. lbs.

495 in. lbs.

175 in. lbs.

0625-20

& 0627-20

Torque

Starting, Stopping and Controlling

Speed

1. To start the tool, grasp the handle fi rmly

and pull the trigger.

2. To vary the speed, increase or decrease

the pressure on the trigger. The further

the trigger is pulled, the greater the

speed.

3. To stop the tool, release the trigger.

Make sure the bit comes to a complete

stop before laying the tool down.

Drilling

Set both the hammer/drill and torque selector

collars to the drill positions.

Place the bit on the work surface and ap-

ply fi rm pressure before starting. Too much

pressure will slow the bit and reduce drilling

effi ciency. Too little pressure will cause the

bit to slide over the work area and dull the

point of the bit.

If the tool begins to stall, reduce pressure

slightly to allow the bit to regain speed. If

the bit binds, reverse the motor to free the

bit from the workpiece.