10

11

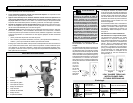

Shifting Speeds (Fig. 8)

Cat. No. 1675-1 has

a gear shift lever on

the right side of the

gear case.

The high setting

(1200 RPM HI) is

the low torque setting

and is designed for

driving Selfeed bits

1-3/8" in diameter

and smaller.

The low setting (300

RPM LO) is the high

torque setting and is

designed for driving

Selfeed bits 1-1/2" in

diameter and larger.

Reversing (Fig. 9)

A reversing switch is located below the trig-

ger switch for removal of bits from holes.

Permit the motor to come to a complete stop

before reversing. Reversing the tool with the

gears in motion may cause severe damage.

When removing selfeed bits from partially

drilled holes, a ick of the trigger switch

will free the threaded pilot screw. When the

threads are loose, lift the bit from the work-

piece with the motor stopped.

Fig. 9

Fig. 8

Chuck Removal

To remove the chuck from the drill:

1. Unplug tool.

2. Fully open the chuck jaws

3. Remove the left-handed thread screw

from inside the chuck by turning it clock-

wise.

4. Pull the chuck off of the spindle.

NOTE: If the chuck does not pull off of

the spindle easily, tap the side of the

chuck with a hammer to loosen it. If this

doesn't work, contact a MILWAUKEE

service center.

WARNING

To reduce the risk of injury, always

wear eye protection.

Drilling

Before drilling, clamp down the material

securely. A poorly secured piece of material

may result in personal injury or inaccurate

drilling. When drilling in light gauge metal or

wood, use a wooden block to back up the ma-

terial to prevent damage to the workpiece.

Mark the center of the hole to be drilled with

a center punch to give the bit a start and to

prevent it from "walking." Lubricate the drill

bit with cutting oil when drilling iron or steel.

Use a coolant when drilling nonferrous met-

als such as copper, brass or aluminum.

To start a selfeed bit, run the threaded feed

screw into the work by icking the trigger

switch, permitting the bit to coast until the

teeth contact the work surface. Align the bit

properly before proceeding. This will reduce

cocking and jamming when starting. To re-

duce jamming on breakthrough, decrease

the drilling pressure when the feed screw

point breaks through the workpiece. Proceed

with steady, even pressure.

Maintaining Tools

Keep your tool in good repair by adopting a

regular maintenance program. Before use,

examine the general condition of your tool.

Inspect guards, switches, tool cord set and

extension cord for damage. Check for loose

screws, misalignment, binding of moving

parts, improper mounting, broken parts and

any other condition that may affect its safe

operation. If abnormal noise or vibration oc-

curs, turn the tool off immediately and have

the problem corrected before further use.

Do not use a damaged tool. Tag damaged

tools “DO NOT USE” until repaired (see

“Repairs”).

Under normal conditions, relubrication is not

necessary until the motor brushes need to

be replaced. After six months to one year,

depending on use, return your tool to the

nearest MILWAUKEE service facility for the

following:

• Lubrication

• Brush inspection and replacement

• Mechanical inspection and cleaning

(gears, spindles, bearings, housing,

etc.)

• Electrical inspection (switch, cord,

armature, etc.)

• Testing to assure proper mechanical and

electrical operation

WARNING

To reduce the risk of injury, always un-

plug your tool before performing any

maintenance. Never disassemble the

tool or try to do any rewiring on the

tool's electrical system. Contact a

MILWAUKEE service facility for ALL

repairs.

WARNING

To reduce the risk of injury, electric

shock and damage to the tool, never

immerse your tool in liquid or allow a

liquid to ow inside the tool.

MAINTENANCE

Cleaning

Clean dust and debris from vents. Keep

the tool handles clean, dry and free of oil

or grease. Use only mild soap and a damp

cloth to clean your tool since certain cleaning

agents and solvents are harmful to plastics

and other insulated parts. Some of these

include: gasoline, turpentine, lacquer thinner,

paint thinner, chlorinated cleaning solvents,

ammonia and household detergents con-

taining ammonia. Never use ammable or

combustible solvents around tools.

Repairs

If your tool is damaged, return the entire tool

to the nearest service center.