6

7

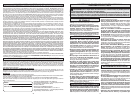

Bracing for forward rotation

C

Fig. 4

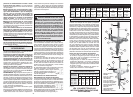

Bracing for reverse rotation

When drilling in reverse, the bit will rotate in a

counterclockwise direction. If the bit binds in the

hole, the bit will come to a sudden stop and the

drill will suddenly react in a clockwise direction.

Figure 5 shows an example of the Super Hole-

Shooter properly braced for reverse rotation.

A. Reverse (counterclockwise) rotation

B. Reaction

C. Brace drill with pipe handle here

If the bit binds, the pipe handle or the motor housing

braced against the stud will hold the drill in position.

When drilling in forward, the bit will rotate in a

clockwise direction. If the bit binds in the hole, the

bit will come to a sudden stop and drill will suddenly

react in a counterclockwise direction.

Figure 4 shows an example of a Super Hole-

Shooter properly braced for forward rotation.

A. Forward (clockwise) rotation

B. Reaction

C. Brace drill with pipe handle here

If the bit binds, the pipe handle or the motor housing

braced against the stud will hold the drill in position.

B

C

A

Fig. 5

Reversing (Fig. 6)

A reversing switch is lo-

cated below the trigger

switch for removal of bits

from holes. Permit the mo-

tor to come to a complete

stop before reversing.

Reversing the tool with the

gears in motion may cause

severe damage. When

removing selfeed bits from

partially drilled holes, a

fl ick of the trigger switch will free the threaded pilot

screw. When the threads are loose, lift the bit from

the workpiece with the motor stopped.

Fig. 6

Chuck Removal

This tool is equipped with a threaded spindle to

hold the chuck. Before

removing the chuck,

unplug the tool and

open the chuck jaws.

A left-handed thread

screw is located inside

the chuck to prevent the

chuck from loosening

when the tool is oper-

ated in reverse direc-

tion. Remove the screw

by turning it clockwise.

To remove the chuck, hold the tool so that only the

side of the chuck rests fi rmly and squarely on a

solid workbench. Insert the chuck key or a chuck

remover bar in one of the keyholes. Turn the chuck

so the key is at about a 30° angle to the bench top

and strike the key sharply with a hammer so the

chuck turns in a counterclockwise direction (look-

ing from the front of the tool). This should loosen

the chuck from the spindle which has a right hand

thread making it easy to remove the chuck by hand.

NOTE: When replacing the chuck, always replace

the left hand thread screw in the chuck.

Fig. 7

WARNING

To reduce the risk of injury,

always wear eye protection.

ACCESSORIES

For a complete listing of accessories refer to your

MILWAUKEE Electric Tool catalog or go on-line

to www.milwaukeetool.com. To obtain a catalog,

contact your local distributor or a service center.

WARNING To reduce the risk of injury,

always unplug the tool before attaching or

removing accessories. Use only specifi cally

recommended accessories. Others may be

hazardous.

Maintaining Tools

Keep your tool in good repair by adopting a regular

maintenance program. Before use, examine the

general condition of your tool. Inspect guards,

switches, tool cord set and extension cord for

damage. Check for loose screws, misalignment,

binding of moving parts, improper mounting, bro-

ken parts and any other condition that may affect

its safe operation. If abnormal noise or vibration

occurs, turn the tool off immediately and have the

problem corrected before further use. Do not use a

damaged tool. Tag damaged tools “DO NOT USE”

until repaired (see “Repairs”).

Under normal conditions, relubrication is not neces-

sary until the motor brushes need to be replaced.

After six months to one year, depending on use,

return your tool to the nearest MILWAUKEE service

facility for the following:

• Lubrication

• Brush inspection and replacement

• Mechanical inspection and cleaning (gears, spin-

dles, bearings, housing, etc.)

• Electrical inspection (switch, cord, armature, etc.)

• Testing to assure proper mechanical and electrical

operation

WARNING To reduce the risk of injury,

electric shock and damage to the tool, never

immerse your tool in liquid or allow a liquid

to fl ow inside the tool.

MAINTENANCE

WARNING To reduce the risk of injury,

always unplug your tool before performing

any maintenance. Never disassemble the tool

or try to do any rewiring on the tool’s electrical

system. Contact a MILWAUKEE service facility

for ALL repairs.

Cleaning

Clean dust and debris from vents. Keep the tool

handles clean, dry and free of oil or grease. Use

only mild soap and a damp cloth to clean your

tool since certain cleaning agents and solvents

are harmful to plastics and other insulated parts.

Some of these include: gasoline, turpentine, lacquer

thinner, paint thinner, chlorinated cleaning solvents,

ammonia and household detergents containing

ammonia. Never use fl ammable or combustible

solvents around tools.

Repairs

If your tool is damaged, return the entire tool to the

nearest service center.

If the bit binds, the drill will suddenly react in the

opposite direction of the rotation of the bit. Figure

3 shows the path of reaction, (B) if the drill bit binds

while being driven in forward (A).The operator

should reduce the chances of a sudden reaction

by following the instructions listed below.

The operator should also prepare for a sudden

reaction by holding securely using the pipe handle

or bracing against a solid fi xed object.

To reduce the chance of bit binding:

• Use sharp bits. Sharp bits are less likely to bind

when drilling.

• Use the proper bit for the job. There are many

types of bits designed for specifi c purposes.

• Avoid drilling warped, wet, knotty, and or pitchy

material if possible.

• Avoid drilling in material that you suspect contains hid-

den nails or other things that may cause the bit to bind.

The direction of reaction is always opposite of the

direction of bit rotation.

Reaction is even more likely to occur when enlarg-

ing already existing holes and at the point when the

bit breaks through the other side of the material.

Drilling

Before drilling, clamp the material down securely.

A poorly secured piece of material may result in

personal injury or inaccurate drilling. When drilling

in light gauge metal or wood, use a wooden block

to back up the material to prevent damage to the

workpiece.

Mark the center of the hole to be drilled with a

center punch to give the bit a start and to prevent

it from "walking." Lubricate the drill bit with cutting

oil when drilling iron or steel. Use a coolant when

drilling nonferrous metals such as copper, brass or

aluminum.

WARNING To reduce the risk of electric

shock, check work area for hidden pipes and

wires before drilling or driving screws.