4

5

Direct Current

Volts

No Load Revolutions per Minute

(RPM)

Underwriters Laboratories, Inc.

United States and Canada

• Hold power tool by insulated gripping sur-

faces, when performing an operation where the

fastener may contact hidden wiring. Fasteners

contacting a “live” wire may make exposed metal

parts of the power tool “live” and could give the

operator an electric shock.

• Keep hands away from all cutting edges and

moving parts.

• Maintain labels and nameplates. These carry

important information. If unreadable or missing,

contact a MILWAUKEE service facility for a free

replacement.

• WARNING: Some dust created by power sanding,

sawing, grinding, drilling, and other construction

activities contains chemicals known to cause

cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement and other

masonry products, and

• arsenic and chromium from chemically-treated

lumber.

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well

ventilated area, and work with approved safety

equipment, such as those dust masks that are spe-

cially designed to fi lter out microscopic particles.

3

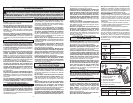

1

2

4

6

1. Bit holder collar

2. Clutch adjusting ring

3. Speed selector

4. Lock switch

5. Fuel Gauge

6. Forward/reverse switch

5

FUNCTIONAL DESCRIPTION

SYMBOLOGY

SPECIFICATIONS

Cat. No. Volts DC No Load RPM

2101-20 4 Low 200

High 600

SPECIFIC SAFETY RULES

• When battery pack is not in use, keep it away

from other metal objects like paper clips,

coins, keys, nails, screws, or other small metal

objects that can make a connection from one

terminal to another. Shorting the battery termi-

nals together may cause burns or a fi re.

• Under abusive conditions, liquid may be eject-

ed from the battery; avoid contact. If contact

accidentally occurs, fl ush with water. If liquid

contacts eyes, additionally seek medical help.

Liquid ejected from the battery may cause irritation

or burns.

SERVICE

• Have your power tool serviced by a qualifi ed

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

WARNING Recharge only with

the charger specified for the battery. For

specific charging instructions, read the

operator’s manual supplied with your charger

and battery.

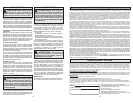

Inserting the Battery into the Tool

1

Slot

Tab

Line

Lock

Line up the tabs on the battery with the slots in the

tool opening. Slide the battery all the way into the

tool. Turn the battery clockwise to lock it in place.

The line on the battery will line up with the

on

the tool. The tool will not run if the battery is not

properly locked into the tool.

Removing the Battery from the Tool

Turn the battery cap counterclockwise to unlock.

Pull the battery out of the tool.

Checking the Fuel Gauge

To determine the amount of charge left in the bat-

tery, press the forward/reverse switch. The Fuel

Gauge will light up for 2-3 seconds.

ASSEMBLY

2

WARNING To reduce the risk of injury,

wear safety goggles or glasses with side-

shields.

WARNING Always remove battery

pack before changing or removing ac-

cessories. Only use accessories specifi cally

recommended for this tool. Others may be

hazardous.

Installing Bits

Always remove the battery before inserting or

removing bits. Select the proper style and size bit

for the type of screw you are using.

1. To install the bit, pull out the collar. Press the bit

into the socket until the collar snaps back and

the bit is locked into place.

2. To remove the bit, pull out the collar, then pull

out the bit.

NOTE: It is not necessary to hold the collar out

when installing and removing bits.

Adjusting the Handle

The handle is designed for convenience and con-

trol. The durable, center pivot allows the handle to

be used in the conventional shape or folded into a

pistol grip. Access to the forward/reverse switch and

lock switch is comfortable in either handle position.

Using the Adjustable Clutch

This tool has an adjustable clutch

for driving different types of screws

into different materials. When prop-

erly adjusted, the clutch will slip at

a preset torque to prevent driving

the screw too deep and to prevent

damage to the screw or tool.

To adjust the clutch, turn the clutch

adjusting ring so that the desired

setting (1-21) lines up with the arrow

on the motor housing, as shown.

The torque specifications shown here are ap-

proximate values obtained with a fully charged

battery pack.

Using the Lock Switch

When the battery is installed, the tool is in operat-

ing condition. The lock switch prevents accidental

starting by locking the forward/reverse switch. Al-

ways set the lock switch to “lock” before performing

maintenance, changing accessories,

storing the tool and any time the tool

is not in use.

1. To lock, push the lock switch to

display the lock

symbol.

2. To unlock, push the lock switch to

display the unlock

symbol.

Selecting High or Low Speed

1. For low speed and more torque,

push the speed selector back ("1"

is displayed).

2. For high speed and less torque,

push the speed selector forward

("2" is displayed).

Selecting Forward or Reverse

Press and hold the top of the switch ◄ for forward

rotation, and the bottom of the switch ► for reverse

rotation. The switch will automatically return to the

center OFF position when it is released.

Automatic Shut-Off

To prevent extra driving force after the selected

torque has been reached, the tool will automatically

shut off if the clutch slips. At higher clutch settings,

this feature may not immediately engage. Release

the switch to reset the automatic shut-off.

Cold Weather Operation

MILWAUKEE Lithium-Ion battery packs are de-

signed to operate in temperatures below freezing.

When the battery pack is too cold, it may need to

warm up before normal use. Put the battery on a

tool and use the tool in a light application. It may

“buzz” for a short time until it warms up. When the

buzzing stops, use the tool normally.

Unlock

Lock

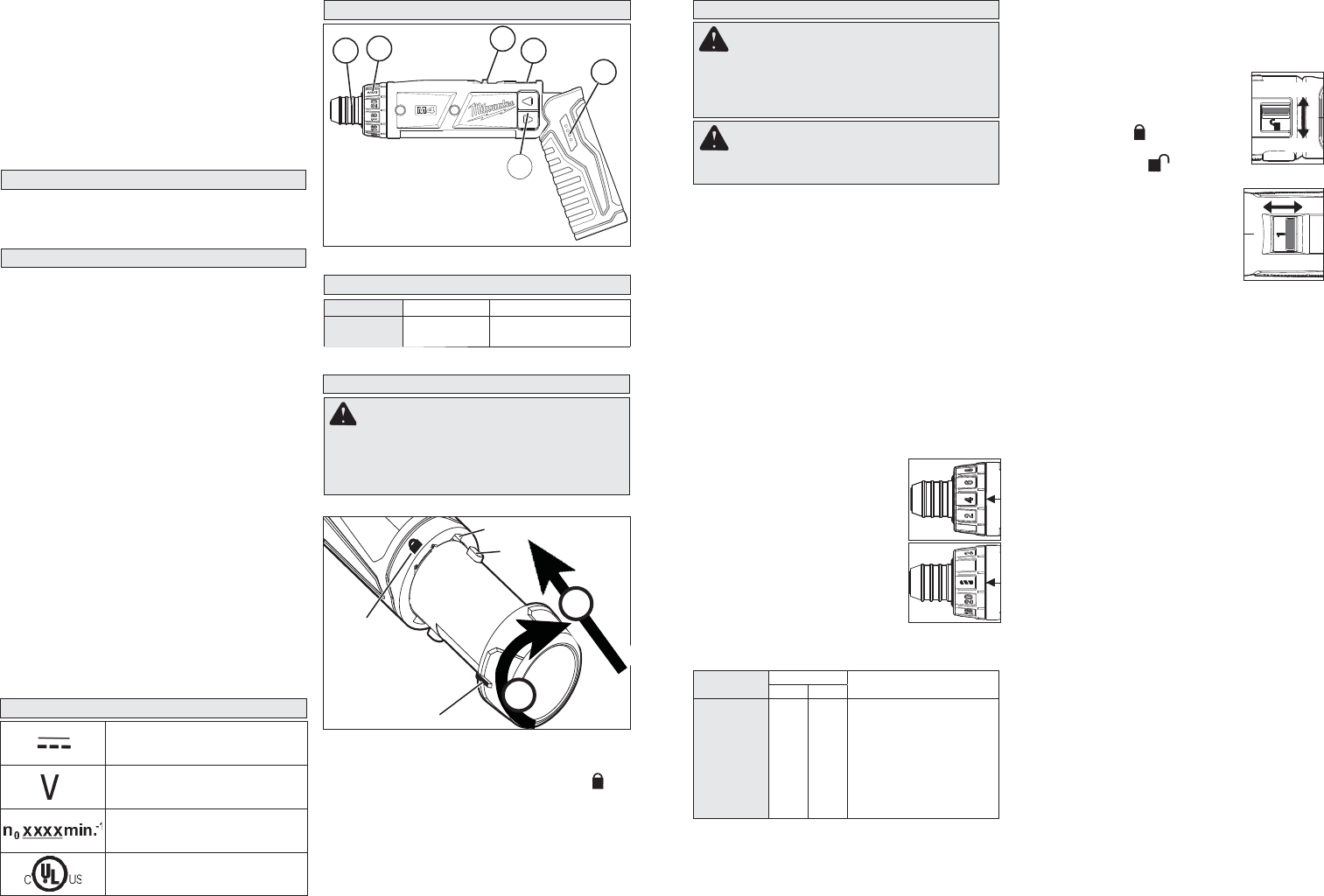

OPERATION

Clutch

Setting

(in lbs)

Applications

Lo Hi

1

4

7

10

13

16

19

3.7

6.5

9.3

12.8

16.4

20.0

23.4

3.7

6.5

9.3

11.2

N/A

N/A

N/A

Small screws in softwood.

Medium screws in soft-

wood or small screws in

hardwood.

Large screws in soft-

woods. Medium screws in

hardwood or large screws

in hardwood with pilot

hole.

Drilling

Driving

HI LO

* When set to high speed, set the clutch at 10 or below.

The Automatic Shut-Off may not work at higher clutch

settings (see "Automatic Shut-Off").

NOTE: Because the settings shown in the table are

only a guide, use a piece of scrap material to test

the different clutch settings before driving screws

into the workpiece.