6

7

NOTE: Because the settings shown in the table are only

a guide, use a piece of scrap material to test the different

clutch settings before driving screws into the workpiece.

Selecting Speed

The speed selector is on top of the motor housing.

Allow the tool to come to a complete stop before

changing speeds. See “Applications” for recom-

mended speeds under various

conditions.

1. For Low speed, push the

speed selector to display “1”.

2. For High speed, push the

speed selector to display “2”.

Using the Control Switch

The control switch may be set to three positions:

forward, reverse and lock. Due to a lockout mecha-

nism, the control switch can only be adjusted when

the ON/OFF switch is not pressed. Always allow

the motor to come to a complete stop before using

the control switch.

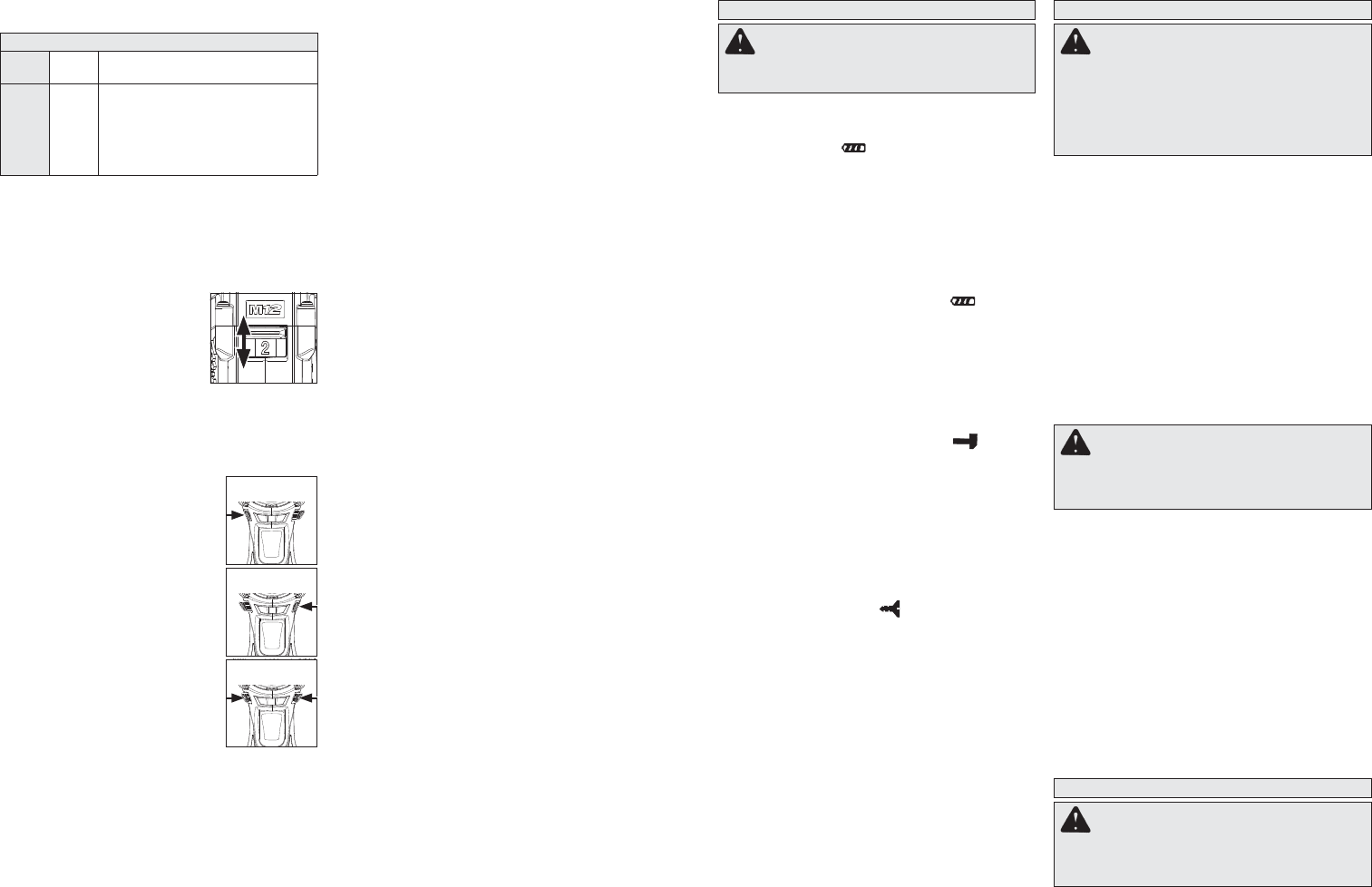

For forward (clockwise) rotation,

push in the control switch from the

right side of the tool. Check the

direction of rotation before use.

For reverse (counterclockwise)

rotation, push in the control switch

from the left side of the tool. Check

direction of rotation before use.

To lock the trigger, push the control

switch to the center position. The

trigger will not work while the con-

trol switch is in the center locked

position. Always lock the trigger

or remove the battery pack before

performing maintenance, changing

accessories, storing the tool and

any time the tool is not in use.

Torque Specifi cations

Clutch

Setting in. lbs

Applications

1-5

6-10

11-15

16-18

5-15

16-22

23-28

29-40

Small screws in softwood.

Medium screws in softwood or small

screws in hardwood.

Large screws in softwoods. Medium

screws in hardwood or large screws in

hardwood with pilot hole.

The torque specifi cations shown here are approximate

values obtained with a fully charged battery pack.

Starting, Stopping and Controlling Speed

1. To start the tool, grasp the handle fi rmly and pull

the trigger.

NOTE: An LED is turned on when the trigger is

pulled.

2. To vary the speed, increase or decrease the

pressure on the trigger. The further the trigger

is pulled, the greater the speed.

3. To stop the tool, release the trigger. Make sure

the bit comes to a complete stop before laying

the tool down.

Battery Pack Protection

To protect the battery from damage and extend

its life, the tool’s intelligent circuit monitors current

draw, temperature, and voltage drops.

In extremely high torque, binding, stalling, and short

circuit situations that cause high current draw, the

tool will vibrate for about 5 seconds, the fuel gauge

will fl ash, and then the tool will turn OFF. To reset,

release the trigger.

Under extreme circumstances, the internal tem-

perature of the battery could become too high.

If this happens, the fuel gauge will fl ash and the

battery pack will shut off. Let the battery pack cool

and then continue work.

Reverse -

Push from

LEFT

Lock -

Push to

CENTER

Forward -

Push from

RIGHT

MAINTENANCE

WARNING To reduce the risk of per-

sonal injury and damage, never immerse your

tool, battery pack or charger in liquid or allow

a liquid to fl ow inside them.

WARNING To reduce the risk of injury,

always unplug the charger and remove the

battery pack from the charger or tool before

performing any maintenance. Never disas-

semble the tool, battery pack or charger.

Contact a MILWAUKEE service facility for

ALL repairs.

ACCESSORIES

For a complete listing of accessories refer to your

MILWAUKEE Electric Tool catalog or go online

to www.milwaukeetool.com. To obtain a catalog,

contact your local distributor or service center.

WARNING Always remove battery pack

before changing or removing accessories.

Only use accessories specifi cally recommend-

ed for this tool. Others may be hazardous.

Maintaining Tool

Keep your tool, battery pack and charger in good

repair by adopting a regular maintenance program.

After six months to one year, depending on use,

return the tool, battery pack and charger to a

MILWAUKEE service facility for:

• Lubrication

• Mechanical inspection and cleaning (gears,

spindles, bearings, housing, etc.)

• Electrical inspection (battery pack, charger,

motor)

• Testing to assure proper mechanical and

electrical operation

If the tool does not start or operate at full power

with a fully charged battery pack, clean the contacts

on the battery pack. If the tool still does not work

properly, return the tool, charger and battery pack,

to a MILWAUKEE service facility for repairs.

Cleaning

Clean dust and debris from charger and tool

vents. Keep tool handles clean, dry and free of oil

or grease. Use only mild soap and a damp cloth

to clean the tool, battery pack and charger since

certain cleaning agents and solvents are harmful to

plastics and other insulated parts. Some of these

include gasoline, turpentine, lacquer thinner, paint

thinner, chlorinated cleaning solvents, ammonia

and household detergents containing ammonia.

Never use flammable or combustible solvents

around tools.

Repairs

For repairs, return the tool, battery pack and char-

ger to the nearest service center listed on the back

cover of this operator's manual.

APPLICATIONS

WARNING To reduce the risk of elec-

tric shock, check work area for hidden pipes

and wires before drilling or driving screws.

Drilling in Wood, Composition Materials and

Plastic

When drilling in wood, composition materials and

plastic, select the

drill-only operating mode.

Start the drill slowly, gradually increasing speed as

you drill. When drilling into wood, use wood augers

or twist drill bits. Always use sharp bits. When using

twist drill bits, pull the bit out of the hole frequently

to clear chips from the bit fl utes. To reduce the

chance of splintering, back work with a piece of

scrap wood. Select low speeds for plastics with a

low melting point.

Drilling in Metal

When drilling in metal, select the

drill-only

operating mode. Use high speed steel twist drills

or hole saws. Use a center punch to start the hole.

Lubricate drill bits with cutting oil when drilling in

iron or steel. Use a coolant when drilling in nonfer-

rous metals such as copper, brass or aluminum.

Back the material to prevent binding and distortion

on breakthrough.

Drilling in Masonry

When drilling in masonry, select the hammer

drill operating mode. Use high speed carbide-tipped

bits. Drilling soft masonry materials such as cinder

block requires little pressure. Hard materials like

concrete require more pressure. A smooth, even

fl ow of dust indicates the proper drilling rate. Do not

let the bit spin in the hole without cutting. Do not

use water to settle dust or to cool bit. Both actions

will damage the carbide.

Driving Screws and Nut Running

Drill a pilot hole when driving screws into thick or

hard materials. Select the

driving screws mode.

Set the torque selector collar to the proper position

and set the speed to low. Use the proper style and

size screwdriver bit for the type of screw you are

using. With the screwdriver bit in the screw, place

the tip of the screw on the workpiece and apply fi rm

pressure before pulling the trigger. Screws can be

removed by reversing the motor.

Overloading

Continuous overloading may cause permanent

damage to tool or battery pack.