4

5

FUNCTIONAL DESCRIPTION

SYMBOLOGY

SPECIFICATIONS

Cat. No. Volts DC No load OPM Hex Wrench

2426-20 12 5000 - 20,000 5 mm

Direct Current

Underwriters Laboratories, Inc.

United States and Canada

SPECIFIC SAFETY RULES

• Use power tools only with specifi cally desig-

nated battery packs. Use of any other battery

packs may create a risk of injury and fi re.

• When battery pack is not in use, keep it away

from other metal objects like paper clips,

coins, keys, nails, screws, or other small metal

objects that can make a connection from one

terminal to another. Shorting the battery termi-

nals together may cause burns or a fi re.

• Under abusive conditions, liquid may be eject-

ed from the battery; avoid contact. If contact

accidentally occurs, fl ush with water. If liquid

contacts eyes, additionally seek medical help.

Liquid ejected from the battery may cause irritation

or burns.

SERVICE

• Have your power tool serviced by a qualifi ed

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

• Hold power tool by insulated gripping surfaces,

when performing an operation where the cutting

accessory may contact hidden wiring or its own

cord. Cutting accessory contacting a "live" wire may

make exposed metal parts of the power tool "live"

and could give the operator an electric shock.

• Use clamps or another practical way to secure

and support the workpiece to a stable platform.

Holding the work by hand or against your body

leaves it unstable and may lead to loss of control.

•To reduce the risk of explosion, electric shock

and property damage, always check the work

area for hidden gas pipes, electrical wires or wa-

ter pipes when making blind or plunge cuts.

• Keep hands away from all cutting edges and

moving parts. Do not reach underneath the

workpiece.

• Do not use dull or damaged blade, which can

cause excessive friction, blade binding and kick-

back.

• Know your workpiece. Remove nail and screw

heads before scraping. Hitting hard objects with

blade may cause the tool to kick back.

• Maintain labels and nameplates. These carry

important information. If unreadable or missing,

contact a MILWAUKEE service facility for a free

replacement.

• WARNING: Some dust created by power sanding,

sawing, grinding, drilling, and other construction

activities contains chemicals known to cause

cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

•lead from lead-based paint

•crystalline silica from bricks and cement and other

masonry products, and

• arsenic and chromium from chemically-treated

lumber.

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well

ventilated area, and work with approved safety

equipment, such as those dust masks that are spe-

cially designed to fi lter out microscopic particles.

ASSEMBLY

WARNING Recharge only with the

charger specifi ed for the battery. For

specifi c charging instructions, read the opera-

tor’s manual supplied with your charger and

battery.

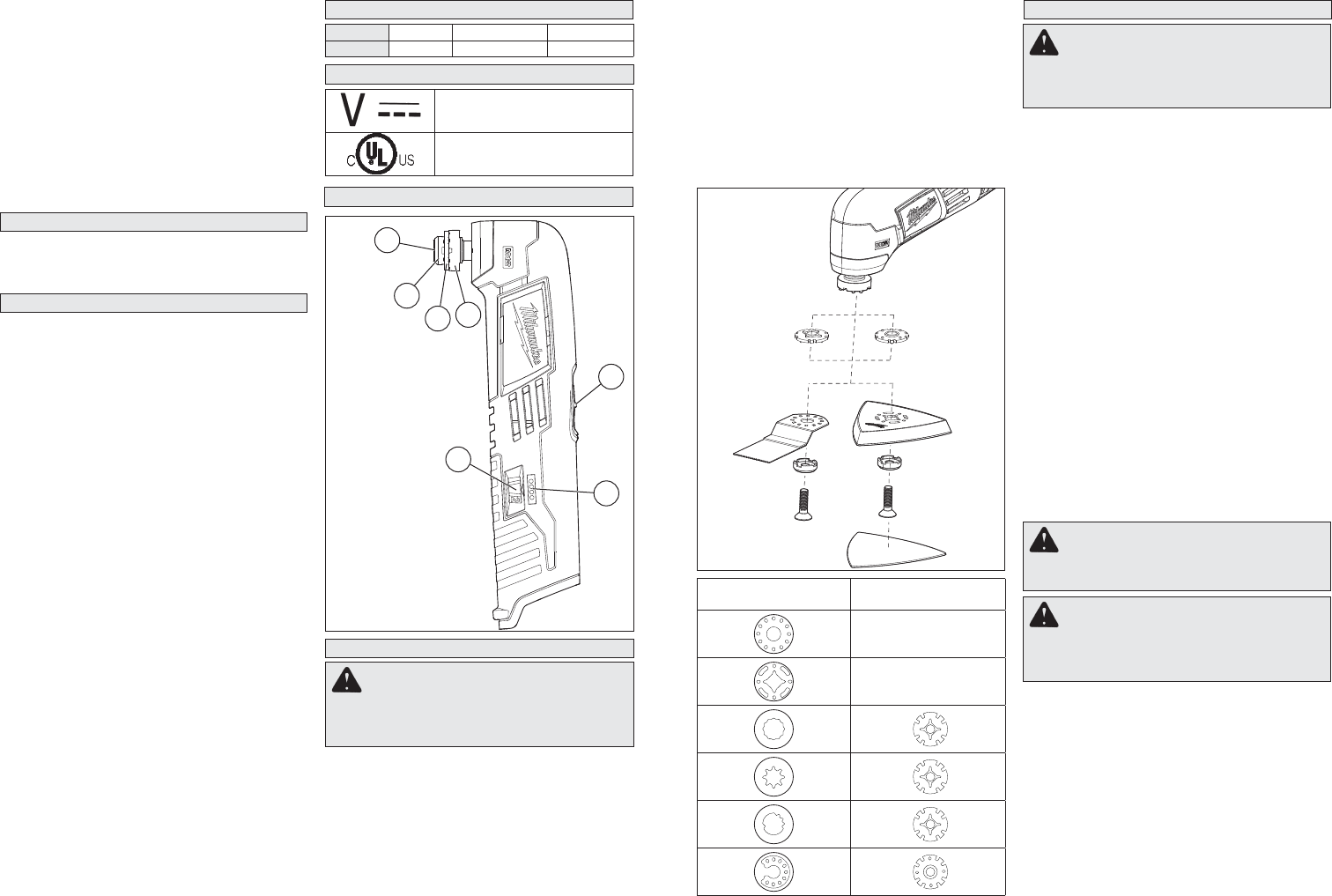

1. Accessory bolt

2. Outer fl ange

3. Adapter

4. Inner fl ange

5. Speed dial

6. Fuel gauge

7. On/Off switch

Changing Accessories

1. Remove the battery pack.

2. Place the tool upside down on a fl at surface.

3. Use the hex wrench to remove the accessory

bolt.

4. Remove the outer fl ange and any accessories

and adapter.

5. Clean bolt, fl anges, adapter and accessories of

all dirt and debris.

6. Place the adapter (if necessary), accessory,

outer fl ange and bolt onto the tool. Determine the

need for an adapter by using the chart. Tighten

securely using a hex wrench.

2

1

5

3

6

7

Accessory Arbor Type

Use adapter with this side

facing accessory

adapter not needed

adapter not needed

4

Inserting/Removing the Battery

To remove the battery, push in the release buttons

and pull the battery pack away from the tool.

To insert the battery, slide the pack into the body of

the tool. Make sure it latches securely into place.

Typical

Accessory

Assemblies

OPERATION

WARNING Always remove battery

pack before changing or removing ac-

cessories. Only use accessories specifi cally

recommended for this tool. Others may be

hazardous.

Fuel Gauge

To determine the amount of charge left in the bat-

tery, turn the tool ON. The Fuel Gauge will light up

for 2-3 seconds. When less than 10% of charge is

left, 1 light on the fuel gauge will fl ash slowly.

To signal the end of charge, 1 light on the fuel gauge

will fl ash quickly for 2-3 seconds and the tool will

not run. Charge the battery pack.

If the tool or battery becomes too hot, the fuel

gauge lights will fl ash in an alternating pattern and

the tool will not run. Allow the tool and battery to

cool down.

To protect against high torque, binding, stalling,

and short circuit situations, the tool will shut down

and all the fuel gauge lights will fl ash. Release the

trigger and restart.

WARNING To reduce the risk of injury,

keep hands away from the blade and all

moving parts. Always wear safety goggles or

glasses with side shields.

WARNING To reduce the risk of explo-

sion, electric shock and property dam-

age, always check the work area for hidden

gas pipes, electrical wires or water pipes

when making blind or plunge cuts.

Typical Applications

A large variety of accessories are available for

applications such as sawing/cutting, scraping,

and sanding.

Sawing/Cutting

Install a sawing/cutting blade at an angle easy to

use. Properly clamp the workpiece. Set the speed

dial to a high speed. Start the tool and allow it to

reach full speed. Use moderate pressure to avoid

burning or scorching the workpiece.

Scraping

Install a scraping blade at an angle easy to use.

Start the tool and allow it to reach full speed. Use

light pressure and a low angle to avoid gouging

and damaging the workpiece.

Sanding

Install a sanding backing pad at an angle easy to

use. Attach a sanding disc, or cut sandpaper to fi t

the backing pad. Generally, use 24 or 36 grit for

heavy stock removal; 50, 60, or 80 grit for medium

stock removal and 120 grit for fi nishing. Always

begin with a coarse grit, using successively fi ner

grits to obtain the desired fi nish.

Properly clamp the workpiece. Start the tool and

allow it to reach full speed. Use light pressure and

long, sweeping, side to side strokes, advancing

forward to produce the desired fi nish.