4 5

2

3

4

1

6

7

8

5

10

11

12

9

13

14

15

16

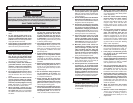

FUNCTIONAL DESCRIPTION

11. WARNING: Some dust created by

power sanding, sawing, grinding, drill-

ing, and other construction activities

contains chemicals known to cause

cancer, birth defects or other reproduc-

tive harm. Some examples of these

chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and ce-

ment and other masonry products,

and

1. Rack

2. Slide

3. Slide locking wing screw

4. Drill motor

5. Grease fi tting

6. Gib adjusting screws

7. Chuck

8. Housing

9. Magnet

10. Adjusting handle

M.T. - Internal Morse Taper Socket

• - 5/8" -11 or 1/2" -13 taps not recommended

**- Requires use of 3/4" shank arbor, Cat. No. 49-57-0030

* - Requires use of #3 MT Arbor, Cat. No. 49-57-0010 or 49-57-0014

Chuck

or Taper

1/2" Chuck

3/4" Chuck

No. 3 M.T.

-

No. 3 M.T.

-

Steel

Hawg™

Cutters

-

4" **

2" *

4" *

3" *

5" *

Amps

6.2

11.5

11.5

-

11.5

-

No

Load

RPM

600

350

750

375

500

250

Drill

5/8"

1-3/8"

3/4"

1-1/4"

1-1/8"

1-1/2"

Coarse

Thread

Tap

3/8" - 16

7/8" - 9

-

7/8" - 9

-

1" - 8

Volts

AC

120

120

120

-

120

-

Speed

--

--

HIGH

LOW

HIGH

LOW

Drill

Motor

Cat. No.

4253-1 •

4262-1

4292-1

-

4297-1

-

Fine

Thread

Tap

5/8" - 18

1" - 14

-

1" - 14

-

1" - 14

Specifi cations

Maximum Recommended Capacity

11. Cord

12. Control panel

13. Control panel socket

14. Wing screw assembly

15. Feed handle

16. Feed handle grip

• arsenic and chromium from chemically-

treated lumber.

Your risk from these exposures varies,

depending on how often you do this

type of work. To reduce your exposure

to these chemicals: work in a well ven-

tilated area, and work with approved

safety equipment, such as those dust

masks that are specially designed to

fi lter out microscopic particles.

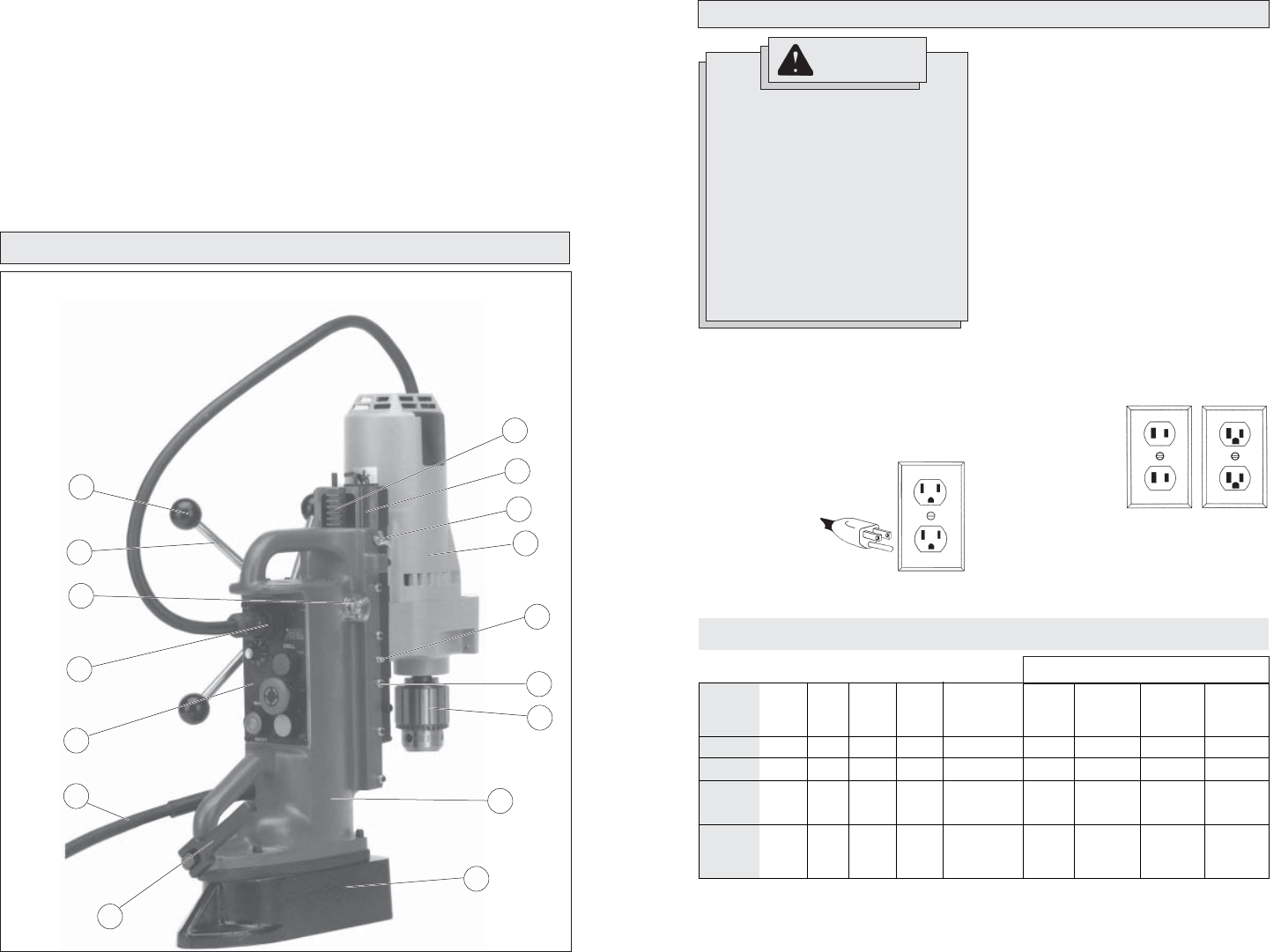

The grounding prong in the plug is connected

through the green wire inside the cord to

the grounding system in the tool. The green

wire in the cord must be the only wire con-

nected to the tool's grounding system and

must never be attached to an electrically

“live” terminal.

Your tool must be plugged into an appropri-

ate outlet, properly installed and grounded in

accordance with all codes and ordinances.

The plug and outlet should look like those

in Figure A.

Double Insulated Tools:

Tools with Two Prong Plugs

Tools marked “Double Insulated” do not

require grounding. They have a special

double insulation system which satisfies

OSHA requirements and complies with the

applicable standards of Underwriters Labora-

tories, Inc., the Canadian Standard Associa-

tion and the National

Electrical Code.

Double Insulated

tools may be used

in either of the 120

volt outlets shown in

Figures B and C.

Grounded Tools:

Tools with Three Prong Plugs

Tools marked “Grounding Required” have a

three wire cord and three prong grounding

plug. The plug must be connected to a prop-

erly grounded outlet (See Figure A). If the

tool should electrically malfunction or break

down, grounding

provides a low re-

sistance path to

carry electricity

away from the user,

reducing the risk of

electric shock.

Fig. B

Fig. C

Fig. A

Improperly connecting the grounding

wire can result in the risk of electric

shock. Check with a qualifi ed electri-

cian if you are in doubt as to whether

the outlet is properly grounded. Do

not modify the plug provided with

the tool. Never remove the grounding

prong from the plug. Do not use the

tool if the cord or plug is damaged.

If damaged, have it repaired by a

MILWAUKEE service facility before

use. If the plug will not fi t the outlet,

have a proper outlet installed by a

qualifi ed electrician.

GROUNDING

WARNING