8 9

WARNING

TOOL ASSEMBLY

To reduce the risk of injury,

always unplug tool before at-

taching or removing accessories

or making adjustments. Use only spe-

cifi cally recommended accessories.

Others may be hazardous.

Grinding Wheel Selection

Only use wheels that:

• are high-strength

• are resinoid bond

• are the proper grit

• are the correct size

• are rated at or above the RPM listed on

the tool's nameplate

• have blotters that cover the entire fl ange

contact area.

Care of Grinding Wheels

Grinding wheels should be protected from"

• wetness and extreme humidity

• any type of solvent

• extreme changes in temperature

• dropping and bumping.

Grinding wheels should be stored:

• in an organized way so wheels can be

removed without disturbing or damaging

other wheels

• with their safety information.

Grinding wheels should NOT be:

• dropped

• rolled

• bumped.

If any wheel is dropped, rolled, bumped, sub-

jected to extreme changes in temperature,

or has come into contact with solvents or

wetness, discard wheel immediately.

WARNING

To reduce the risk of injury and dam-

age to the tool, use ONLY accessories

rated at or above the RPM listed on

the tool's nameplate.

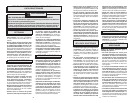

To Test the Wheel:

NOTE: Wheel must be dry to do this test.

1. Suspend the wheel by its arbor hole on

a small pin or a fi nger (Fig. 1).

2. Tap the side of the wheel with the back

of a screwdriver (or any similar, solid,

non-metallic object).

3. Rotate wheel 90° and repeat the test in

three more places.

If the wheel rings, it is in good condition.

If it does not ring, it is bad and should be

discarded.

Fig. 1

Grounded tools require a three wire exten-

sion cord. Double insulated tools can use

either a two or three wire extension cord.

As the distance from the supply outlet

increases, you must use a heavier gauge

extension cord. Using extension cords with

inadequately sized wire causes a serious

drop in voltage, resulting in loss of power

and possible tool damage. Refer to the table

shown to determine the required minimum

wire size.

The smaller the gauge number of the wire,

the greater the capacity of the cord. For ex-

ample, a 14 gauge cord can carry a higher

current than a 16 gauge cord. When using

more than one extension cord to make up

the total length, be sure each cord contains

at least the minimum wire size required. If

you are using one extension cord for more

than one tool, add the nameplate amperes

and use the sum to determine the required

minimum wire size.

Guidelines for Using Extension Cords

• If you are using an extension cord out-

doors, be sure it is marked with the suffi x

“W-A” (“W” in Canada) to indicate that it

is acceptable for outdoor use.

• Be sure your extension cord is prop-

erly wired and in good electrical

condition. Always replace a damaged

extension cord or have it repaired by a

qualifi ed person before using it.

• Protect your extension cords from sharp

objects, excessive heat and

damp or wet areas.

READ AND SAVE ALL INSTRUCTIONS FOR FUTURE USE.

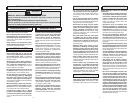

Recommended Minimum Wire Gauge

for Extension Cords*

Extension Cord Length

* Based on limiting the line voltage drop to

fi ve volts at 150% of the rated amperes.

Nameplate

Amperes

0 - 2.0

2.1 - 3.4

3.5 - 5.0

5.1 - 7.0

7.1 - 12.0

12.1 - 16.0

16.1 - 20.0

25'

18

18

18

18

16

14

12

75'

18

18

16

14

12

10

100'

18

16

14

12

10

150'

16

14

12

12

50'

18

18

18

16

14

12

10

EXTENSION CORDS

Grit Selection

The lower the grit number, the coarser the

wheel. Coarser wheels should be used for

rough grinding and fi ner wheels for fi nish

grinding (see "Accessories").

Wheel Material

Grinding wheels are made from various

materials and are meant for different jobs.

Be sure you choose the proper wheel for the

job you plan to do.

MILWAUKEE Straight Grinders use type 1,

straight wheels as defi ned by the American

National Standards Institute (ANSI). Type

1 straight wheels are made to be used for

edge grinding. They are not to be used for

side grinding.

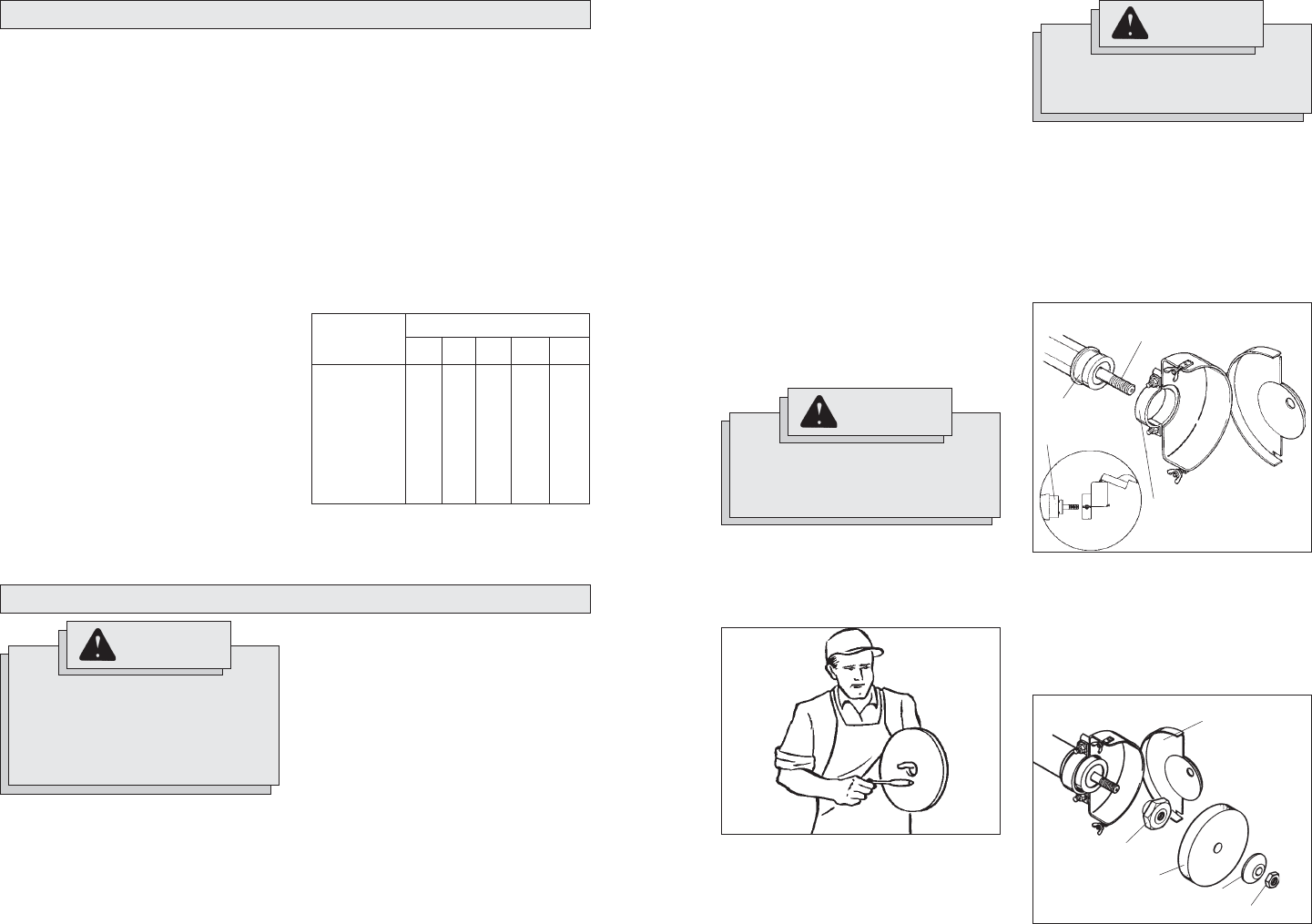

Installing Guard Assemblies

The guards for all tools in this manual are

mounted the same way:

1. Unplug tool and lay it on its tool rest.

2. Loosen guard clamping fasteners.

3. Position guard clamp over the spindle

housing and against the housing shoul-

der (Fig. 2).

Fig. 2

WARNING

To reduce the risk of injury, the wheel

guard must be fl ush with the spindle

housing.

4. Position guard so the operator is always

behind the guard. The open edge of the

guard should face the workpiece.

5. Tighten wheel guard clamps.

Installing Grinding Wheels and Acces-

sories (Cat. No. 5211 only)

Fig. 3

1. Unplug tool and lay it on its tool rest.

2. Loosen wing nuts. Move studs aside and

swing the faceplate away.

Spindle

housing

shoulder

Spindle

Guard clamp

Inner fl ange

Faceplate

Grinding wheel

Outer fl ange

Spindle nut