10 11

WARNING

To reduce the risk of injury, use only

identical replacement parts.

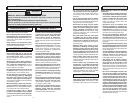

Fig. 4

3. Hold inner fl ange with 1" wrench pro-

vided with the tool.

4. Remove the spindle nut with the 9/16"

wrench provided with the tool.

5. Remove outer fl ange and wheel.

6. Examine both fl anges to ensure that they

are free of nicks and are fl at (Fig. 4).

NOTE: If the fl ange faces are nicked, or

if the inner surfaces of the fl anges are

not fl at, then replace them with identical

replacement parts. On Cat. No. 5211,

the fl anges should evenly contact the

blotter on the wheel.

7. If you are installing a grinding wheel,

inspect and test it for damage (see "To

Test the Wheel").

8. Place the accessory on the spindle.

Never force an accessory onto the

spindle. A forced fi t may damage the

accessory.

9. Replace outer fl ange and spindle nut.

10. Tighten spindle nut. Do not overtighten.

11. Swing the faceplate back into place.

Move studs back into slots. Tighten wing

nuts.

Inner fl ange

Outer fl ange

Installing Grinding Wheels and Acces-

sories (Cat. No. 5223 only)

Fig. 5

1. Unplug tool and lay it on its tool rest.

2. Hold inner fl ange with spanner wrench

provided with the tool.

3. Remove the spindle nut with the 1-1/16"

wrench provided with the tool.

4. Remove outer fl ange, rubber washer,

and wheel.

5. Examine both fl anges to ensure that

they are free of nicks and are fl at (see

Fig. 4).

NOTE: If the fl ange faces are nicked, or

if the inner surfaces of the fl anges are

not fl at, then replace them with identical

replacement parts. On Cat. No. 5223,

the fl anges should evenly contact the

rubber washers on either side of the

wheel.

6. If you are installing a grinding wheel,

inspect and test it for damage (see "To

Test the Wheel").

7. Place the accessory on the spindle.

Never force an accessory onto the

spindle. A forced fi t may damage the

accessory.

8. Replace rubber washer, outer fl ange,

and spindle nut.

9. Tighten spindle nut. Do not overtighten.

Installing Grinding Wheels and Acces-

sories (Cat. No. 5243 only)

1. Unplug tool and lay it on its tool rest.

2. Loosen wing nuts. Move studs aside and

swing the faceplate away.

3. Hold inner fl ange with spanner wrench

provided with the tool.

4. Remove the spindle nut with the 1-1/16"

wrench provided with the tool.

5. Remove outer fl ange, rubber washer,

and wheel.

6. Examine both fl anges to ensure that

they are free of nicks and are fl at (see

Fig. 4).

NOTE: If the fl ange faces are nicked, or

if the inner surfaces of the fl anges are

not fl at, then replace them with identical

replacement parts. On Cat. No. 5243,

the fl anges should evenly contact the

rubber washers on either side of the

wheel.

7. If you are installing a grinding wheel,

inspect and test it for damage (see "To

Test the Wheel").

8. Place the accessory on the spindle.

Never force an accessory onto the

spindle. A forced fi t may damage the

accessory.

9. Replace rubber washer, outer fl ange,

and spindle nut.

10. Tighten spindle nut. Do not overtighten.

11. Swing the faceplate back into place.

Move studs back into slots. Tighten wing

nuts.

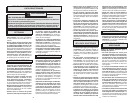

Fig. 6

Inner fl ange

Rubber

washer

Grinding wheel

Outer fl ange

Spindle nut

Inner fl ange

Rubber

washer

Grinding wheel

Outer fl ange

Spindle nut

WARNING

To reduce the risk of injury, wear

safety goggles or glasses with side

shields. Unplug the tool before

changing accessories or making

adjustments.

OPERATION

Starting and Stopping the Tool

1. To start the tool, pull the trigger.

2. To stop the tool, release the trigger.

Using the Trigger Lock Mechanism

The lock button holds the trigger in the 'ON'

position for continuous use.

1. To lock the trigger, hold the lock button

in while pulling the trigger. Then, release

the trigger.

2. To unlock the trigger, pull the trigger and

release. The lock button will pop out.

Grinding

1. Hold handle and spindle housing

fi rmly.

2. Pull trigger.

3. Allow tool to reach full speed.

Always test new wheels for cracks or

damage. To test new wheels, point

the grinder away from you and shield

bystanders from the tool, and then run

the motor at full speed for one minute

while allowing the wheel to spin.

4. Gently apply grinder to the workpiece.