22

23

WARNING To reduce the risk of

personal injury and damage to the tool or

work:

• Always use the “hammering-only” setting to

set the anchor. Never use the “hammering-

with-rotation” setting to set the anchor.

• Never switch the tool to “hammering-with-

rotation” until after the anchor has been

set and the tooth anchor chuck has been

removed from the anchor.

Setting Self-Drilling Anchors (5317-59/59A only)

MILWAUKEE Tooth Anchor Chucks require a “B”

taper adapter.

1. Place the proper size tooth anchor chuck into

the “B” taper adapter. Then insert the “B” taper

adapter into the tool and lock it into place as

described. See “Installing Bits and Chisels”.

2. Insert the anchor

into the tooth an-

chor chuck. Set

the knob for ham-

mering only. Set

the anchor on your

mark and hammer

until the teeth have

penetrated the con-

crete.

3. Set the knob for

hammering with

rotation and drill un-

til the chuck is 1/8"

above the concrete.

NOTE: It may be

necessary to clean

dust and cuttings

from the anchor

several times while

drilling the hole.

4. Remove the anchor

from the hole while

the tool is running.

Clean the dust and

cuttings from the

anchor by pointing it downward and turning the

tool on and off several times. Clean the dust out

of the hole with a vacuum cleaner or blowout bulb.

5. Place the expan-

sion plug into the

anchor and insert

the anchor into the

hole. Switch the

knob back to ham-

1/8"

mering only, and

hammer the anchor

fi rmly into the hole.

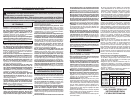

6. Snap the head off

of the anchor. To

remove the head of

anchors up to 5/8",

grasp the handles

fi rmly and pull the

tool sharply to-

wards you or snap

off the anchor head with a hand hammer as

shown. The anchor is now ready to receive a

bolt.

7. To remove the anchor head wedged in the tooth

anchor chuck, use drift pin 48-86-0100.

8. To remove the tooth anchor chuck, remove the

“B” taper adapter from the nose of the tool. Insert

the drift pin supplied with the adapter into the

hole on the side of the “B” taper adapter and

strike it sharply to force out the tooth anchor

chuck.

Chiseling and Chipping

MILWAUKEE Rotary Hammers may be used for

chipping and chiseling.

When chiseling, hold the tool at an angle to the

workpiece. Work from a corner or close to the edge

of the workpiece, breaking off one small area at a

time rather than attempting too large an area.

A variety of accessories are available.

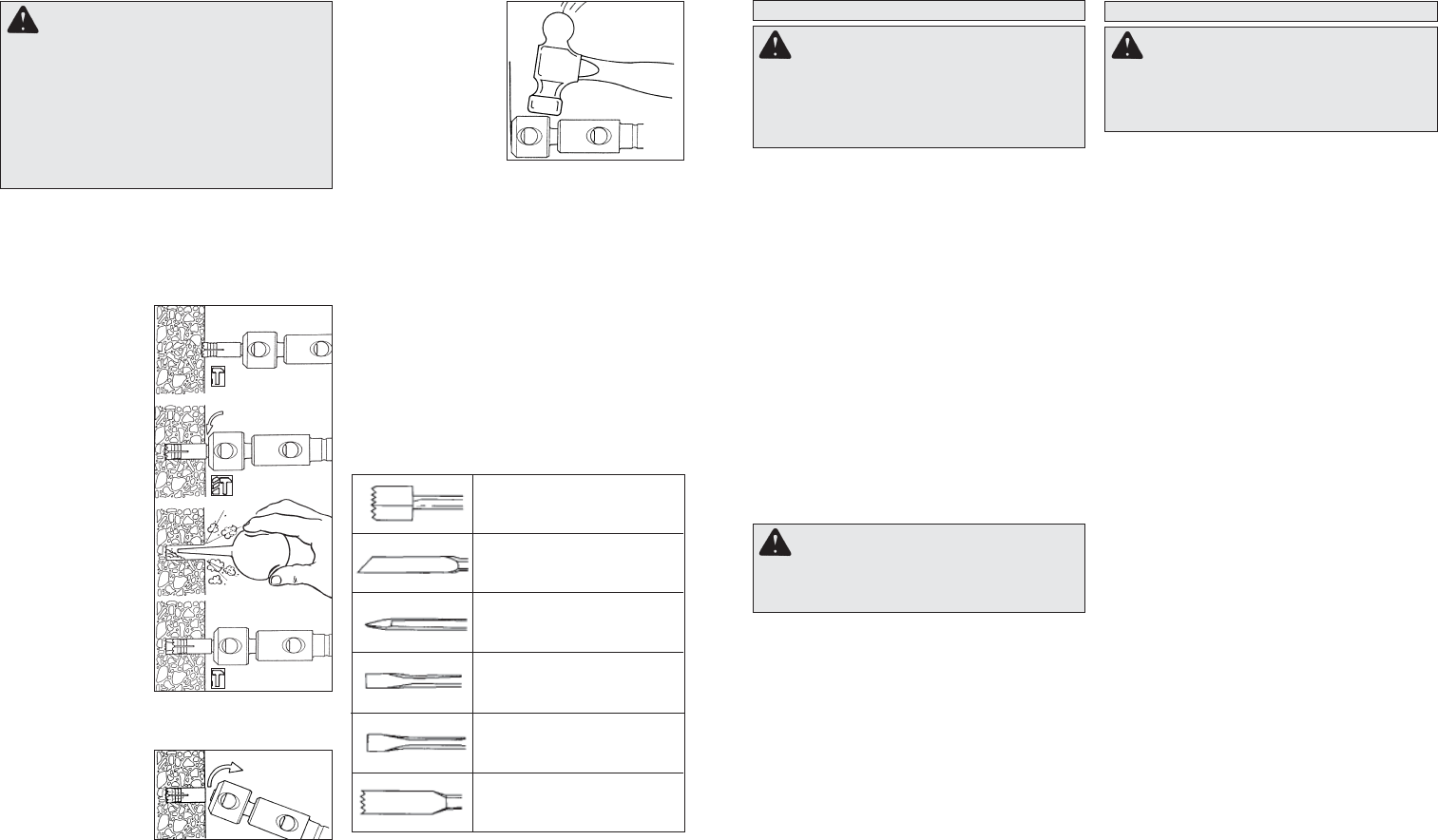

Scaling Chisels

For removing weld spatter or

scale and cutting straight lines.

Bushing Tools

Used to surface concrete.

Mortar Cutting Chisels

(Seam Tools)

For removing old mortar for tuck

pointing or caulking.

Bull Points

For demolition work and starting

holes in concrete slabs.

Flat Chisels

For edging, chipping or

channeling.

Slotting Chisel

For slotting and cutting between

drilled holes in concrete and

masonry.

MAINTENANCE

Maintaining Tools

Keep your tool in good repair by adopting a regular

maintenance program. Before use, examine the gen-

eral condition of your tool. Inspect guards, switches,

tool cord set and extension cord for damage. Check

for loose screws, misalignment, binding of moving

parts, improper mounting, broken parts and any

other condition that may affect its safe operation. If

abnormal noise or vibration occurs, turn the tool off

immediately and have the problem corrected before

further use. Do not use a damaged tool. Tag damaged

tools “DO NOT USE” until repaired (see “Repairs”).

Under normal conditions, relubrication is not neces-

sary until the motor brushes need to be replaced.

After six months to one year, depending on use,

return your tool to the nearest MILWAUKEE service

facility for the following:

• Lubrication

• Brush inspection and replacement

• Mechanical inspection and cleaning (gears,

spindles, bearings, housing, etc.)

• Electrical inspection (switch, cord, armature, etc.)

• Testing to assure proper mechanical and electrical

operation

Cleaning

Clean dust and debris from vents. Keep the tool

handles clean, dry and free of oil or grease. Use

only mild soap and a damp cloth to clean your tool

since certain cleaning agents and solvents are

harmful to plastics and other insulated parts. Some

of these include: gasoline, turpentine, lacquer thin-

ner, paint thinner, chlorinated cleaning solvents,

ammonia and household detergents containing

ammonia. Never use fl ammable or combustible

solvents around tools.

Repairs

If your tool is damaged, return the entire tool to the

nearest service center.

WARNING To reduce the risk of

injury, always unplug your tool before

performing any maintenance. Never disas-

semble the tool or try to do any rewiring

on the tool’s electrical system. Contact a

MILWAUKEE service facility for ALL repairs.

WARNING To reduce the risk of injury,

electric shock and damage to the tool, never

immerse your tool in liquid or allow a liquid

to fl ow inside the tool.

ACCESSORIES

For a complete listing of accessories refer to your

MILWAUKEE Electric Tool catalog or go on-line

to www.milwaukeetool.com. To obtain a catalog,

contact your local distributor or a service center.

WARNING To reduce the risk of injury,

always unplug the tool before attaching or

removing accessories. Use only specifi cally

recommended accessories. Others may be

hazardous.