8 9

WARNING

To reduce the risk of injury, wear

safety goggles or glasses with side

shields. Unplug the tool before

changing accessories or making

adjustments.

OPERATION

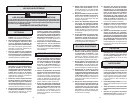

Selecting Action (Fig. 3)

MILWAUKEE 7/8" Rotary Hammers have

two settings: drilling only and hammering

with rotation.

1. To select drilling only, rotate the shift

knob 180° in the direction of the double

arrow so that the tab portion of the knob

points toward the “Drill” symbol. Do not

shift the tool when it is running or coast-

ing to a stop.

When drilling in wood or steel, shift knob

to drilling and use chuck adapter kit (see

“Accessories”).

2. To select hammering with rotation, rotate

the shift knob 180° in the direction of the

double arrow so that the tab portion of

the knob points toward the “Hammer”

symbol.

NOTE: To engage the hammering

mechanism, maintain pressure on

the bit. When pressure on the bit is

released, the hammering action will

stop.

1. For forward (clockwise) rotation, push

the forward/reverse switch to forward

as shown.

2. For reverse (counterclockwise) rota-

tion, push the forward/reverse switch to

reverse as shown. Check the direction

of rotation beofre use. Although an in-

terlock prevents Using forward/reverse

switch (Fig. 4) Check the direction of

rotation before use. Although an inter-

lock prevents reversing the tool while

the motor is running, allow the motor to

come to a full stop before reversing.

Starting, Stopping & Controlling Speed

1. To start the tool, pull the trigger

2. To stop the tool, release the trigger.

3. To vary the driving speed, simply in-

crease or decrease pressure on the

trigger. The further the trigger is pulled,

the greater the speed.

Hammer

symbol

Fig. 3

Drill

symbol

Fig. 4

Forward

Reverse

Forward

Reverse

Using the Forward/Reverse Switch (Fig. 4)

Cold Starting

If this tool is stored for a long period of time

or at cold temperatures, it may not hammer

initially because the lubrication has become

stiff. To warm up the tool:

1. Insert and lock a bit into the tool.

2. Turn the tool on, applying force to the bit

against a concrete or wood surface.

3. Turn the tool on and off every few sec-

onds. In a short time, the tool will start

hammering. The colder the tool is, the

longer it will take to warm it up.

Operation

Position the tool, grasp the handles fi rmly

and pull the trigger.

Always hold the tool securely using both

handles and maintain control. Use only

enough pressure to hold the tool in place

and prevent the tip of the bit from wandering.

This tool has been designed to achieve top

performance with only moderate pressure.

Let the tool do the work.

If the speed begins to drop off when drilling

deep holes, pull the bit partially out of the hole

while the tool is running to help clear dust.

NOTE: Do not use water to settle the dust

since it will clog the bit fl utes and tend to

make the bit bind in the hole. If the bit should

bind, a built-in, non-adjustable slip clutch pre-

vents the bit from turning. If this occurs, stop

the tool, free the bit and begin again.

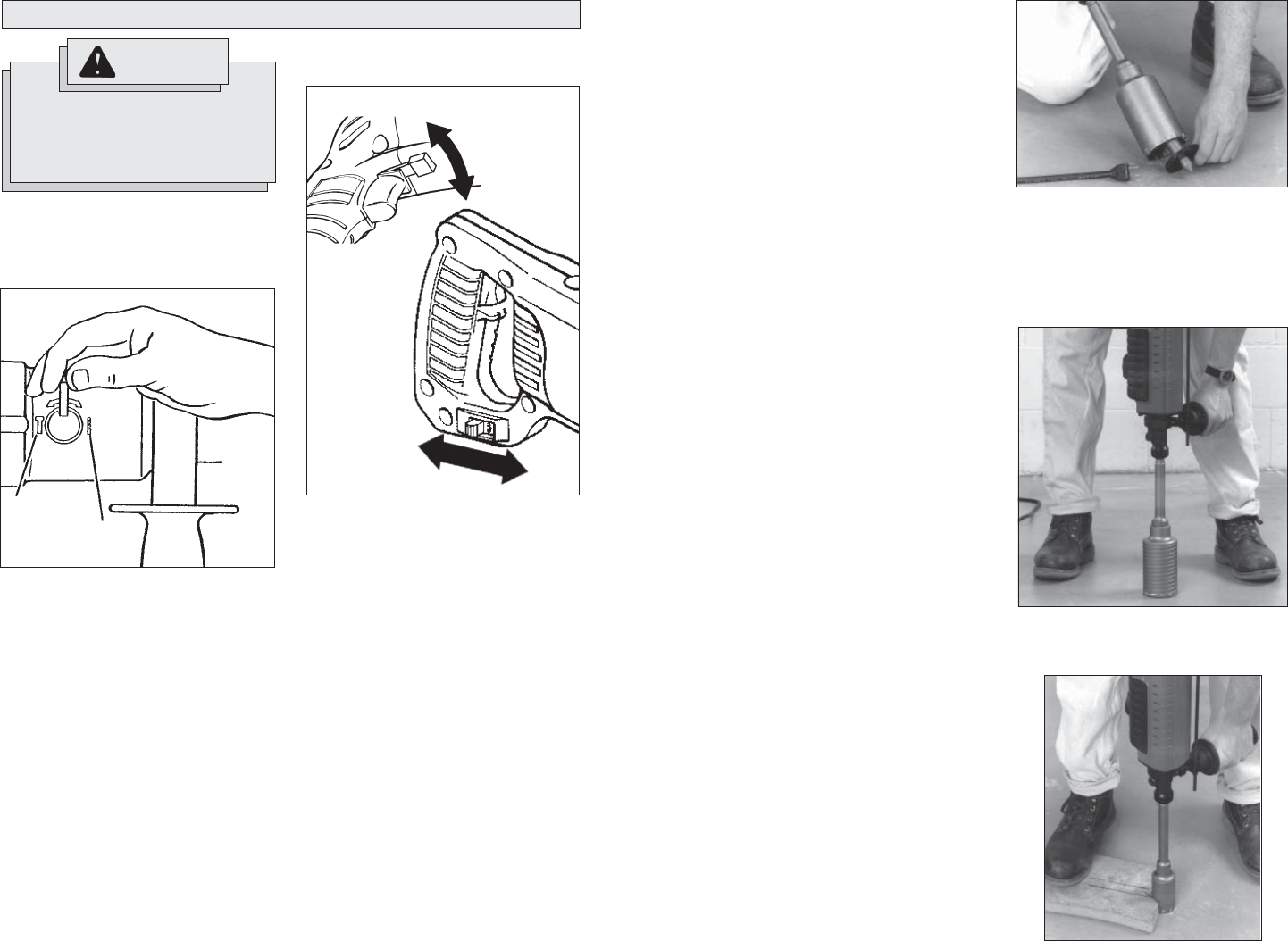

Fig. 7

Using Rotary Percussion Core Bits (Fig.

5 - 8)

Core bits are useful for drilling larger holes

for conduit and pipe. MILWAUKEE Thin Wall

Core Bits have heat-treated steel bodies with

durable carbide tips. These core bits are spe-

cially designed for fast, accurate drilling with

combined hammering and rotary action.

1. Clean and lubricate the threads on

the adapter and core bit to make later

removal easier. Screw the threaded end

of the adapter into the rear of the core

bit.

NOTE: For core bits 1- 1/4" and larger,

push the guide plate onto the pointed

end of the center pin. Insert the center

pin and guide plate assembly into the

core bit. Be sure the small end of the

center pin is securely placed into the

hole in the center of the core bit (Fig. 5).

2. Insert the adapter into the nose of the

tool as described in “Installing Bits”. Set

the hammer/drill shift knob to hammer-

ing with rotation.

3. Press the center pin fi rmly against your

center mark, hold the tool fi rmly and pull

the trigger (Fig. 6).

NOTE: If a center pin and guide plate are

not available, use a template or notched

board to start the hole (Fig. 7).

Fig. 5

Fig. 6