10 11

If the tool or screw are misaligned,

the screw will not drive into the work

surface or it will not drive straight.

2. Pull the trigger and push the tool forward

with a “punching” motion to sink the

screw into the drywall. A punching mo-

tion will engage the snap-action clutch,

cause the screw to start rotating, sink

the screw and disengage the snap-ac-

tion clutch within a fraction of a second.

If pressure is not maintained on the tool

after engaging the snap-action clutch,

the screw will not properly seat.

The snap-action clutch will automatically

disengage and the insert bit will stop

rotating once the screw has been driven

to the selected depth.

These screwdrivers feature a snap-ac-

tion clutch, which may ratchet slightly

when the screw is sunk to the selected

depth.

NOTE: Practice driving screws into

pieces of scrap material to become

familiar with the tool and the snap-

action clutch action before attempting to

drive screws into the workpiece.

3. To remove screws, remove the loca-

tor assembly and switch the forward/

reverse switch to the reverse position.

Reattaching the locator assembly will

not change the depth setting.

1. Select the proper drywall screw for each

job. Pilot holes are not needed. To insert

screws, place the screw onto the insert

bit, then align the screw against the work

surface, making sure to hold the tool and

screw square to the work surface.

APPLICATIONS

WARNING

To reduce the risk of explosion,

electric shock and property dam-

mage. always check the work area

for hidden pipes and wires before

drilling.

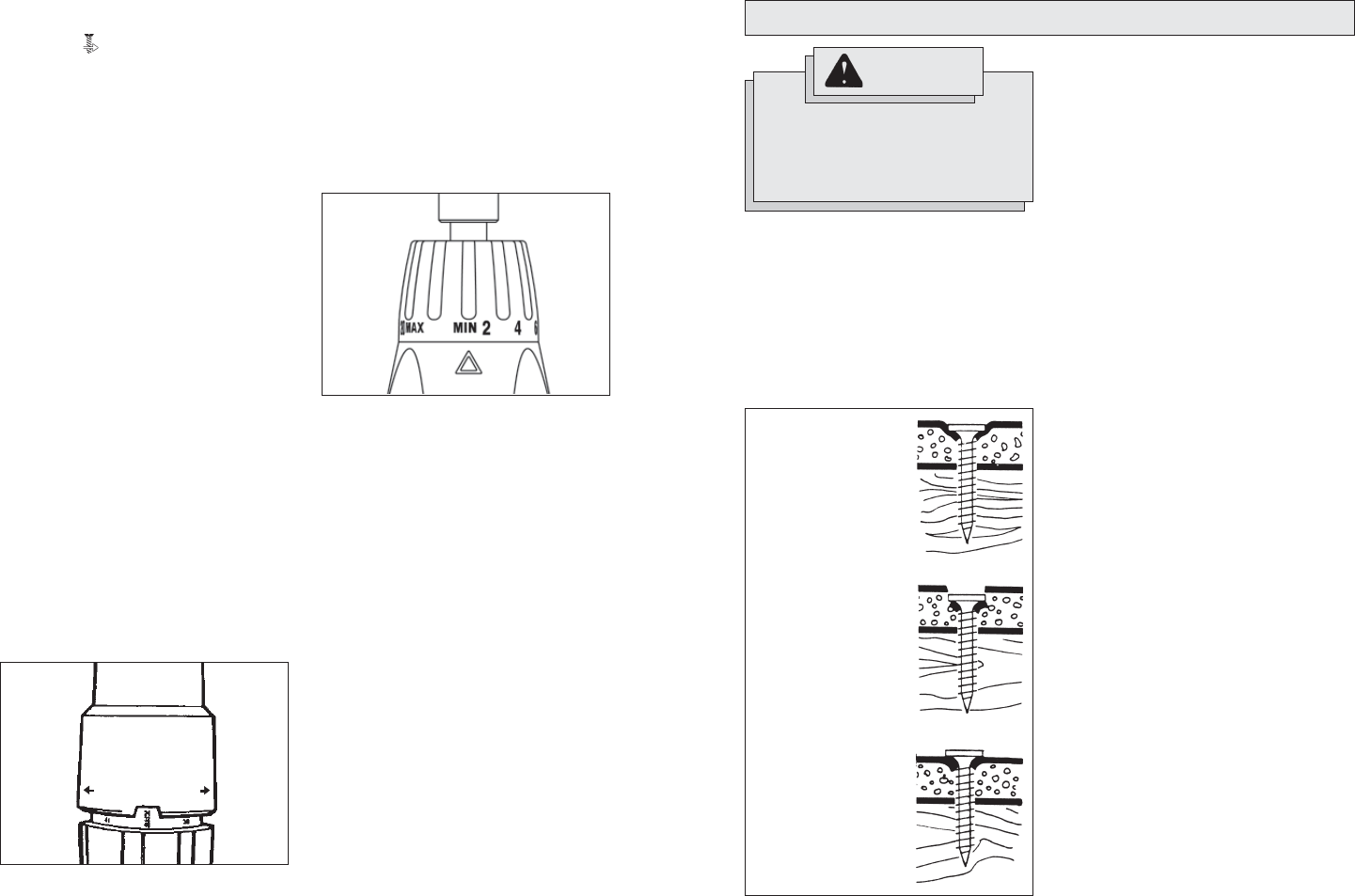

Driving Drywall Screws (Fig. 11)

For Screwdrivers Rated 0-4000 RPM

Standard drywall screws are generally

designed for attaching drywall to wood

studs and 26 through 20-gauge steel studs.

MILWAUKEE Screwdrivers are ideal for

driving these types of drywall screws. The

depth setting is very important. Refer to the

guide below for the correct depth setting

(Fig. 11).

Correct. Head of screw

is below surface, but

does not puncture fac-

ing.

Too deep. Head of

screw punches hole in

drywall surface, making

finishing difficult and

allowing moisture be-

neath facing. Decrease

depth.

Too shallow. Head of

screw extends above

drywall face and can

not be finished off.

Increase depth.

Fig. 11

Adjusting Torque Setting

These screwdrivers have a torque setting

adjustment collar for driving different types

of screws into different materials. When

properly adjusted, the clutch will slip at a

preset torque to prevent driving the screw

too deep and to prevent damage to the

screw or tool.

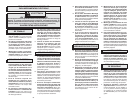

For Cat. Nos. 6580-20 & 6581-20 (Fig. 9)

The 6580-20 Screwdriver has a torque

setting adjustment collar that may be

adjusted to one of forty-four settings.

The torque is adjustable from 10 to 140

inch-pounds.

The 6581-20 Screwdriver has a torque

setting adjustment collar that may be

adjusted to one of thirty-three settings.

Beyond setting thirty-three, the tool will stall

before slipping the clutch. The torque is ad-

justable from 10 to 110 inch-pounds.

To select a setting, turn the adjustment

collar in the direction indicated on the tool.

The selected setting will appear in the

window as shown (Fig. 9).

HIGHER -TORQUE - LOWER

SETTING

Fig. 9

2. To decrease the driving depth, simply

rotate the locator in the direction

labeled .

The detents “lock” the locator in place,

ensuring an accurate depth setting.

3. To remove the locator assembly, turn

the ramp-off sleeve while pulling it

away from the tool. Reattaching the

locator assembly will not change the

depth setting.

NOTE: Use a piece of scrap material to

test the different settings before driving

screws into workpiece. To determine a

specifi c setting for your application, use a

torque wrench to check the correct torque

at any particular setting.

NOTE: Use a piece of scrap material to

test the different settings before driving

screws into workpiece. To determine a

specifi c setting for your application, use a

torque wrench to check the correct torque

at any particular setting.

For Cat. No. 6780-20 (Fig. 10)

The 6780-20 Screwdriver has a torque

setting adjustment collar that may be

adjusted to one of twenty-one settings.

The torque is adjustable from 10 to 140

inch-pounds.

To select a setting, turn the adjustment

collar on the tool. The selected setting

will appear above the arrow as shown

(Fig. 10).

Fig. 10