page 6

OPERATION

To reduce the risk of injury, wear safety goggles or glasses

with side shields.

WARNING!

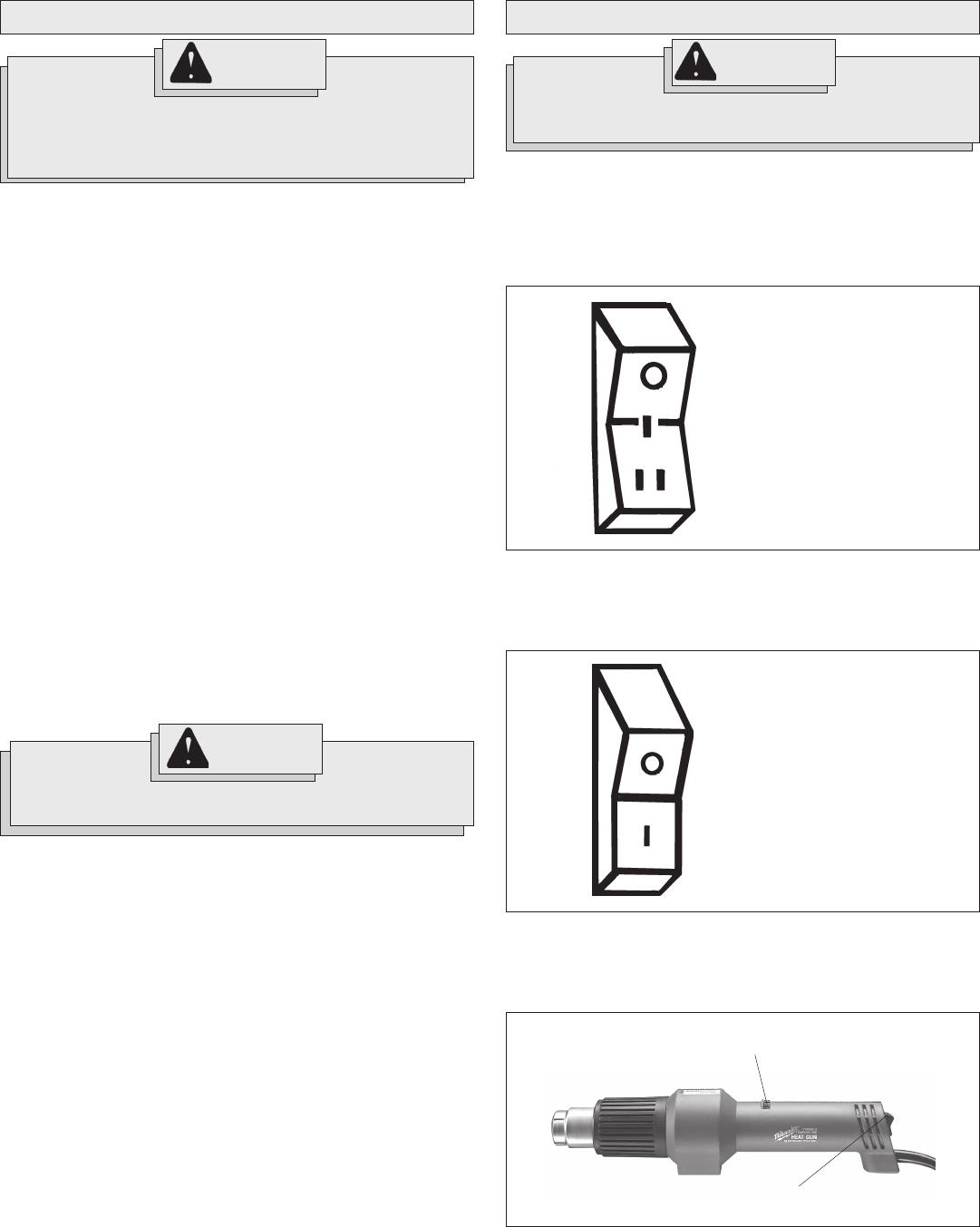

Using the Temperature Control Switch (Fig. 1-4)

Cat. No. 8975 (Fig. 1)

Dual temperature control heat guns are provided with a 3 position rocker

switch. Place the switch in the center position for Low range or press

in the lower position of the switch completely for High range. The

markings on the switch correspond to these positions:

Cat. No. 8977 (Fig. 2)

Variable temperature model heat guns are marked O for OFF and l for

ON. Temperature is controlled by turning the end cap in the directions

dictated by the arrows.

Fig. 1

Fig. 2

Cat. No. 8978 (Fig. 3)

Electronic temperature control system heat guns allow the tool to pro-

duce a greater concentration of heat at the nozzle, allowing the use of

various accessory nozzles.

Fig. 3

Heat adjustment knob

On / off switch

TOOL ASSEMBLY

Installing Reduction Nozzles

Reduction nozzles are used to intensify the application of heat in a

specific area.

For reduction nozzle Cat. No. 49-80-0297:

1. To install the reduction nozzle to the heat gun, slide the nozzle onto

the heat gun nose.

2. Adjust heat, distance and length of application as necessary.

For reduction nozzles Cat. No. 49-80-0305, 49-80-0306 (For use with

electronic controlled heat guns 8978, 8986-20 and 8988-20 only):

1. To install the reduction nozzle to the heat gun, align the grooves on

the nozzle with the grooves on the heat gun nose.

2. Slide the nozzle onto the nose.

3. Adjust heat, distance and length of application as necessary.

Installing Slit and Cutting Nozzles

The slit nozzle Cat. No. 49-80-0308 is used for lap welding. The cutting

nozzle Cat. No. 49-80-0309 is used as a heated cutting edge.

NOTE: The reduction nozzle Cat. No. 49-80-0305 is needed as an at-

tachment for the slit and cutting nozzles. (For use with electronic con-

trolled heat guns 8978, 8986-20 and 8988-20 only):

1. To install the reduction nozzle to the heat gun, align the grooves on

the nozzle with the grooves on the heat gun nose and slide the nozzle

onto the nose.

2. Slide the slit or cutting nozzle onto the reduction nozzle.

3. Adjust heat, distance and length of application as necessary.

Installing Air Directing Nozzles

Air directing nozzles are used to change the direction of the airflow.

For hook nozzle Cat. No. 49-80-0292, deflector Cat. No. 49-80-0293,

air spreader Cat. No. 49-80-0294, soldering reflector nozzle Cat. No.

49-80-0307:

1. To install an air directing nozzle to the heat gun, slide the nozzle onto

the heat gun nose.

2. Adjust heat, distance and length of application as necessary.

For air reflector Cat. No. 49-80-0307 (For use with electronic controlled

heat guns 8978, 8986-20 and 8988-20 only):

1. To install the air reflector nozzle to the heat gun, align the grooves on

the nozzle with the grooves on the heat gun nose.

2. Slide the nozzle onto the nose.

3. Adjust heat, distance and length of application as necessary.

To reduce the risk of injury, always unplug tool before

attaching or removing accessories or making adjustments.

Use only specifically recommended accessories. Others

may be hazardous.

WARNING!

To reduce the risk of injury, do not remove accessory tips

until tool has cooled to room temperature.

WARNING!

O = Off

I = Low Temperature

570° F (300° C)

I I = High Temperature

1000° F (540° C)

O = Off

I = On