page 5

WARNING!

TOOL ASSEMBLY

To reduce the risk of injury, always unplug

tool before attaching or removing accessories

or making adjustments. Use only specifically

recommended accessories. Others may be

hazardous.

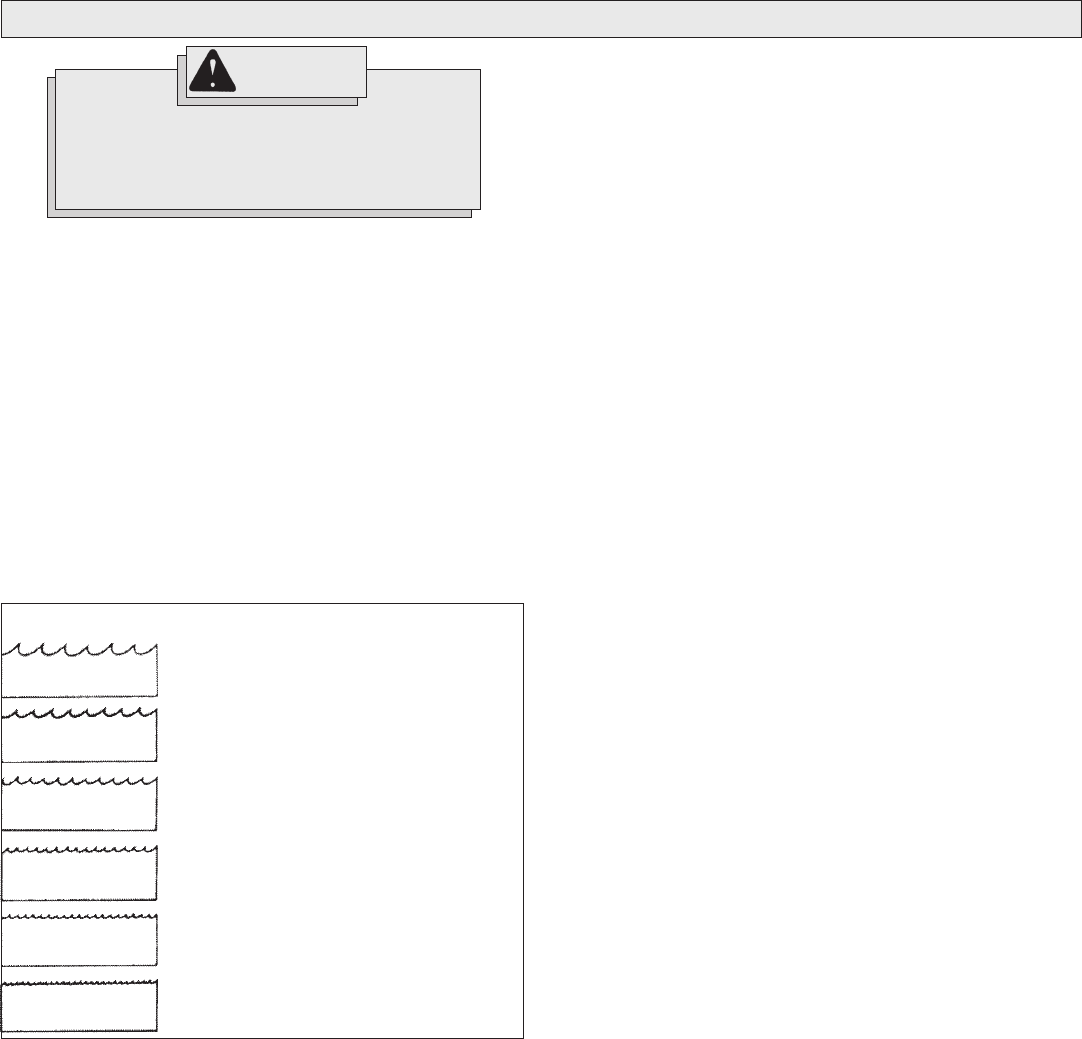

Blades and Blade Selection (Fig. 1)

Every MILWAUKEE Portable Bandsaw is furnished with a 14-teeth-per-

inch Bi-metal blade which is suitable for most applications. The blade

dimensions required for the band saws are: .020" thickness, 1/2" width

and 44-7/8" in length. The special .020" thickness reduces flexure fa-

tigue and provides maximum tooth life. To maximize cutting life, use a

blade with the correct pitch (teeth per inch) for the specific cutting job.

Blades are available in several pitches. To select the proper blade, three

factors should be considered: The size, shape, and type of material to

be cut.

The following suggestions are for selecting the right blade for various

cutting operations. Keep in mind that these are broad guidelines and that

blade requirements may vary depending upon the specific size, shape

and type of material to be cut. Generally, soft materials require coarse

pitch blades and hard materials require fine pitch blades. Use coarse

pitch blades for thick work and fine pitch blades for thin work. It is

important to keep at least three teeth in the cut (see "Typical Application").

Changing Blades

1. UNPLUG THE TOOL BEFORE REMOVING OR INSTALLING BLADES.

2. Turn the tension lock handle located on the front of the saw 180°

counterclockwise. This releases the tension on the blade for easy

removal.

3. Remove the blades from the pulley first and then from the guides.

4. To install a new blade, with the pulleys facing up, insert the blade

between the rollers and the faces of the guides, making sure that

the teeth on the left side of the tool point towards the rear of the tool.

5. With one hand, hold the blade in place between the rollers and the

guides and use the other hand to position the blade around the

pulleys. Be sure that the blade lies freely within the guard channel

before starting the tool motor.

6. Turn the tension lock handle 180° clockwise to lock the position. This

will secure the blade on the pulleys.

BE SURE THAT THE BLADE IS PROPERLY SEATED ON THE

PULLEYS BEFORE STARTING THE CUT.

• For tough stock 1/2" to 3-3/8" in diameter

or width (available in carbon steel only).

• For tough stock 3/8" to 1" in diameter or

width (available in carbon steel only).

• For tough stock 3/16" up to 4-3/4" in

diameter or width.

• For tough stock 5/32" to 3/4" in diameter

or width.

• For thin-wall tubing and thin sheets

heavier than 21 gauge.

• For thin-wall tubing and thin sheets

heavier than 21 gauge.

6 Teeth per Inch

8 Teeth per Inch

10 Teeth per Inch

14 Teeth per Inch

18 Teeth per Inch

24 Teeth per Inch

Fig. 1