7

WARNING!

ASSEMBLY

Always lock trigger or remove

battery pack before changing or

removing accessories. Only use

accessories specifically

recommended for this tool.

Others may be hazardous.

WARNING!

To reduce the risk of injury, always

use a side handle when using this

tool. Always brace or hold securely.

Installing the Side Handle

1. To install the side handle, loosen the

side handle grip until the ring is large

enough to slide over the torque selec-

tor collar. The raised rib on the side

handle ring fits inside the groove

around the tool. Rotate the handle to

the desired position and tighten the

side handle until it is secure.

2. To remove the side handle, loosen

the side handle grip until the ring is

large enough to slide off the tool.

OPERATION

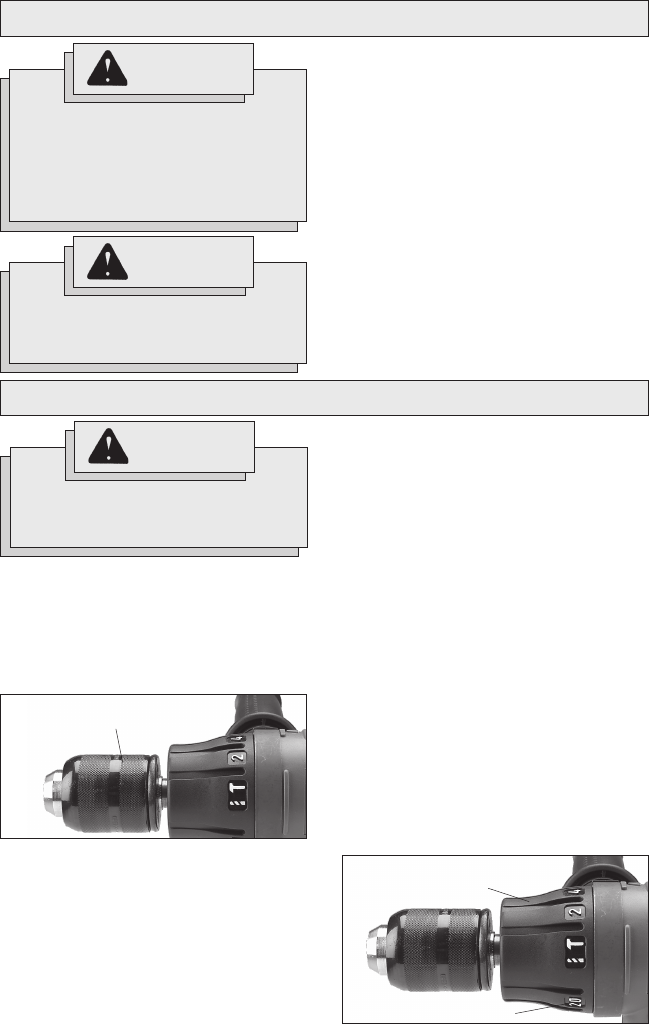

Using Keyless Chucks (Fig. 3)

Your cordless tool is equipped with a spindle

lock. The chuck can be tightened with one

hand, creating higher grip strengths on the bit.

Always remove the battery pack or lock

the trigger before inserting or removing bits.

1. To open the chuck jaws, turn the sleeve

in the counterclockwise direction.

When using drill bits, allow the bit to

strike the bottom of the chuck. Center

the bit in the chuck jaws and lift it about

1/16" off of the bottom.

When using screwdriver bits, insert

the bit far enough for the chuck jaws

to grip the hex of the bit.

2. To close the chuck jaws, turn the

sleeve in the clockwise direction. The

bit is secure when the chuck makes a

WARNING!

To reduce the risk of injury, wear

safety goggles or glasses with

side shields.

ratcheting sound and the sleeve can

not be rotated any further.

3. To remove the bit, turn the sleeve in

the counterclockwise direction.

NOTE: A ratcheting sound may be heard

when the chuck is opened or closed. This

noise is part of the locking feature, and

does not indicate a problem with the chuck's

operation.

The torque specifications shown here are

approximate values obtained with a fully

charged battery pack.

Using Clutch (Fig. 4)

This tool has an adjustable clutch for driv-

ing different types of screws into differ-

ent materials. When properly adjusted, the

clutch will slip at a preset torque to pre-

vent driving the screw too deep and to

prevent damage to the screw or tool.

To adjust the clutch, turn the torque selec-

tor collar to one of the twenty positions

shown on the collar. The number must line

up with the arrow on top of the tool.

Fig. 3

Sleeve

Fig. 4

Torque selector

collar

Position numbers