MVC-64E/EW PLATE COMPACTOR — OPERATION & PARTS MANUAL — REV. #0 (05/11/06) — PAGE 21

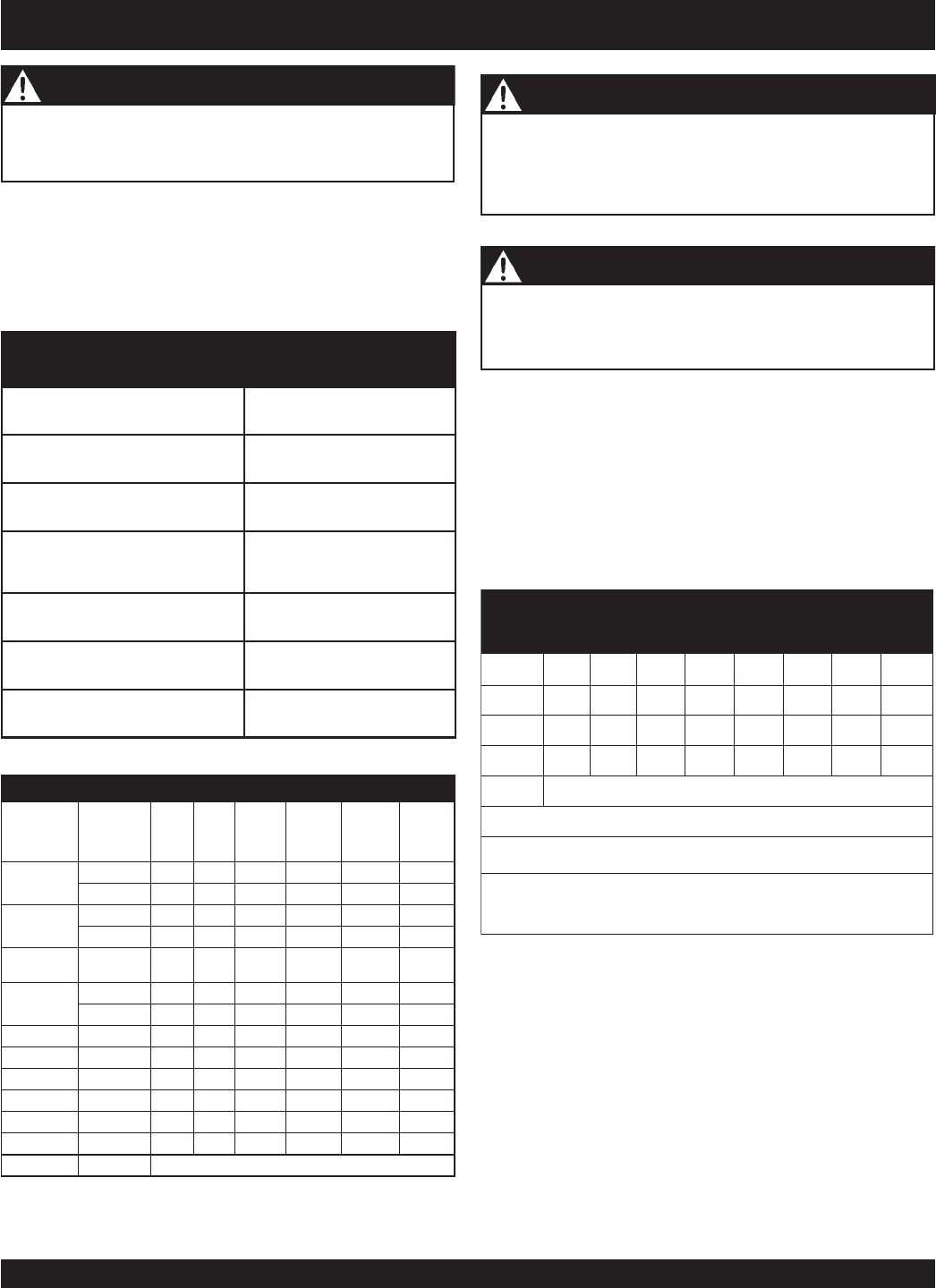

Inspection and Maintenance Service Tables.

1. To make sure your plate compactor is always in good

working condition before using, carry out the maintenance

inspection in accordance with Tables 5 through 7.

MVC-64E/EW — MAINTENANCE

ECNANETNIAMENIGNE.6elbaT

)3(NOITPIRCSEDNOITAREPOEROFEB

TSRIF

HTNOM

RO

.SRH01

3YREVE

SHTNOM

RO

.SRH52

6YREVE

SHTNOM

RO

.SRH05

YREVE

RAEY

RO

.SRH0

01

YREVE

SRAEY2

RO

.SRH002

liOenignE

KCEHCX

EGNAHCX

renaelCriA

KCEHCX

EGNAHC)1(X

stloB&stuNllA

fInethgit-eR

yrasseceN

X

gulPkrapS

NAELC-KCEHCX

ECALPER X

sniFgnilooCKCEHCX

retserrAkrapSNAELC X

knaTleuFNAELC X

retliFleuFKCEHC X

deepSeldITSUJ

DA-KCEHC )2(X

ecnaraelCevlaVTSUJDA-KCEHC )2(X

senilleuFKCEHC )2()yrassecenfiecalper(sraey2yrevE

nidesunehwylt

neuqerferomecivreS)1( YTSUD .saera

yllacinahcemeradnaslootreporpehtevahuoysselnu,relaedcivresruoyybdeciv

resebdluohssmetiesehT)2(

serudecorpecivresroflaunaMNIBORehtotrefeR.tneiciforp

.slavretniecnanetniamrepo

rpenimretedotnoitarepofosruohgol,esulaicremmocroF)3(

.7ELBAT

retemaiD)mc/gk.ni(EUQROTGNINETHGIT

lairetaM

mm6 mm8 mm01 mm21 mm41 mm61 mm81 mm02

T4 07 051 003 005 057 001,1 004,1 000,2

T8-6 001 052 005 008 003,1 000,2 007,2 008,3

T11 051 004 008 002,1 000,2 009,2 002,4 006,5

* )mm01(007~056)mm8(053~003)mm6(001

)munimulafositrap-retnuocesacnI(*

)dednahthgirllaeraenihcamsihthtiwesunisdaerhT(

,tlobhcaenodekramsilairetamfoytilauqdnalairetaM

.wercsdna

z

Check for leakage of fuel or oil.

z

Remove soil and clean the bottom of compaction plate.

z

Check engine oil, see page 16.

z

Check for loose screws including tightness. See Table 7

below (tightening torque ), for retightening:

Daily Service

WE/E46-HVM.5ELBATNOITCEPSNIENIHCAM

METINOITAREPOFOSRUOH

straPdegamaD)yadyreve(sruoh8yrevE

swercStsoLroesooL)yadyreve(sruoh8yrevE

metsySgnillor

tnoCfonoitcnuF

traP

)yadyreve(sruoh8yrevE

kcehCliOrotarbiVsruoh001yrevE

tnemecalpeRliOrotarbiVsruoh003yrevE

kcehC)hctulc(tleb-Vsruoh002yrevE

ENGINE OIL

1. Drain the engine oil when the oil is

warm

as shown in

Figure 22.

2. Remove the oil drain bolt and sealing washer and allow

the oil to drain into a suitable container.

3. Replace engine oil with recommended type oil as listed

in Table 4. Engine oil capacity is .634 quarts (.6 liters). DO

NOT overfill.

4. Install drain bolt with sealing washer and tighten se-

curely.

Inspection and other services should

always

be carried out

on hard and level ground with the engine shut down.

CAUTION

These inspection intervals are for operation under normal

conditions. Adjust your inspection intervals based on the

number hours plate compactor is in use, and particular

working conditions.

CAUTION

Fuel piping and connections should be replaced every 2

years.

CAUTION