PAGE 10 — PS7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #8 (07/26/10)

INCH

MM

0

25

50

0

1

2

3

75

100

125

150

175

200

230

255

280

305

330

355

380

15

9

10

11

12

13

14

4

5

6

7

8

WATER PUMP

WATER PUMP

OFF

ON

ON

WATER

OFF

BRAKES:

This saw is equipped with parking brakes.

This saw is equipped with parking brakes.

Brakes are applied automatically when engine

Brakes are applied automatically when engine

is off and dis-engaged when engine is running.

is off and dis-engaged when engine is running.

BEFORE

STARTING:

WATER

SUPPLY:

BLADES:

STARTING

ENGINE:

STOPPING

ENGINE:

FWD-

NEUTRAL-

NEUTRAL-

REV

CONTROL:

RAISE-

RAISE-

LOWER

FUNCTION:

Check all fluid levels. Secure blade firmly to

Check all fluid levels. Secure blade firmly to

bladeshaft. Make sure all protective guards

bladeshaft. Make sure all protective guards

are in place and properly mounted. Wear eye,

are in place and properly mounted. Wear eye,

ear protection and protective clothing.

ear protection and protective clothing.

Connect water supply to water inlet. Move

Connect water supply to water inlet. Move

water ON/OFF CONTROL to ON position.

water ON/OFF CONTROL to ON position.

Adjust WATER FLOW CONTROL lever to

Adjust WATER FLOW CONTROL lever to

desired position. Drain watering system in

desired position. Drain watering system in

cold weather to prevent damage due to

cold weather to prevent damage due to

freezing.

freezing.

Always follow blade manufacturer's

Always follow blade manufacturer's

recommendations for blade selection,

recommendations for blade selection,

speed and application.

speed and application.

NEVER exceed blade manufacturer's

NEVER exceed blade manufacturer's

maximum rated RPM. See operator's manual

maximum rated RPM. See operator's manual

for detailed blade mounting instructions.

for detailed blade mounting instructions.

Set CONTROL HANDLE to NEUTRAL position.

Set CONTROL HANDLE to NEUTRAL position.

Set THROTTLE to IDLE. Turn start switch to

Set THROTTLE to IDLE. Turn start switch to

ON position. Wait for glow plug indicator light

ON position. Wait for glow plug indicator light

to go out. Momentarily turn switch to start

to go out. Momentarily turn switch to start

position; release switch as soon as engine

position; release switch as soon as engine

starts. Allow engine to warm up for several

starts. Allow engine to warm up for several

minutes before increasing engine speed. Use

minutes before increasing engine speed. Use

approved diesel fuel only.

approved diesel fuel only.

Do not stop engine abruptly when hot! Reduce

Do not stop engine abruptly when hot! Reduce

THROTTLE to IDLE and allow engine to run 1

THROTTLE to IDLE and allow engine to run 1

to 2 minutes before turning ignition switch off.

to 2 minutes before turning ignition switch off.

Damage to engine may occur if not allowed to

Damage to engine may occur if not allowed to

cool adequately.

cool adequately.

The panel mounted handle controls

The panel mounted handle controls

FORWARD, NEUTRAL and REVERSE

FORWARD, NEUTRAL and REVERSE

operation. Neutral position stops or holds saw

operation. Neutral position stops or holds saw

in a stationary position. Incremental

in a stationary position. Incremental

movement in the FORWARD or REVERSE

movement in the FORWARD or REVERSE

direction will increase speed proportionate

direction will increase speed proportionate

to amount of movement.

to amount of movement.

RAISE-LOWER function is controlled by the

RAISE-LOWER function is controlled by the

switch mounted at the right side of the

switch mounted at the right side of the

CONTROL HANDLE. Push toggle switch

CONTROL HANDLE. Push toggle switch

lever forward to lower saw. Pull toggle switch

lever forward to lower saw. Pull toggle switch

lever backward to raise saw.

lever backward to raise saw.

OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

FORWARD

NEUTRAL

REVERSE

WARNING

BLADESHAFT ROTATIONDIS -ENGAGEMENT SYSTEM

BLADESHAFT ROTATIONDIS -ENGAGEMENT SYSTEM

Engine must be at idle when engaging or

Engine must be at idle when engaging or

dis-engaging bladeshaft drive.

dis-engaging bladeshaft drive.

To stop bladeshaft rotation:

To stop bladeshaft rotation:

Push rocker switch labeled BLADESHAFT forward.

Push rocker switch labeled BLADESHAFT forward.

Engine will tilt forward, dis-engaging the belt drive.

Engine will tilt forward, dis-engaging the belt drive.

To start bladeshaft rotation:

To start bladeshaft rotation:

Push rocker switch labeled BLADESHAFT backward.

Push rocker switch labeled BLADESHAFT backward.

Engine will tilt back, engaging belt drive.

Engine will tilt back, engaging belt drive.

ENGINE MUST BE SHUT OFF

ENGINE MUST BE SHUT OFF

when removing or installing

when removing or installing

blade or bladeguard or performing any type of service

blade or bladeguard or performing any type of service

to bladeshaft or any other component on machine!

to bladeshaft or any other component on machine!

NEVER

attempt to remove or install blade or bladeguard

attempt to remove or install blade or bladeguard

with engine running by dis-engaging the belt drive!

with engine running by dis-engaging the belt drive!

NEVER

attempt to service any component with the

attempt to service any component with the

engine running!

engine running!

NEVER

leave saw unattended while engine is running!

leave saw unattended while engine is running!

RAISE/LOWER

SWITCH

FWD-NEUTRAL-REV

CONTROL

NEVER EXCEED BLADE MANUFACTURER'S RECOMMENDED RPM'S

NEVER EXCEED BLADE MANUFACTURER'S RECOMMENDED RPM'S

ADJUST WATER FLOW VALVE

ADJUST WATER FLOW VALVE

FOR DESIRED WATER FLOW

FOR DESIRED WATER FLOW

WATER

FLOW

CONTROL

TO ADJUST CUT DEPTH INDICATOR:

TO ADJUST CUT DEPTH INDICATOR:

LOWER SAW UNTIL BLADE CONTACTS

LOWER SAW UNTIL BLADE CONTACTS

SURFACE, ADJUST DIAL TO ZERO.

SURFACE, ADJUST DIAL TO ZERO.

DEPTH

INDICATOR

To Control Depth of Cut with Saw

To Control Depth of Cut with Saw

Running and Blade Mounted:

Running and Blade Mounted:

Step 1:

Step 1:

Raise saw above desired cutting depth.

Raise saw above desired cutting depth.

Step 2:

Step 2:

Turn depth control knob counterclockwise

Turn depth control knob counterclockwise

until saw cannot be lowered by pushing raise/lower

until saw cannot be lowered by pushing raise/lower

switch forward.

switch forward.

Step 3:

Step 3:

Hold raise/lower switch in the lowering

Hold raise/lower switch in the lowering

position and rotate the depth control knob clockwise

position and rotate the depth control knob clockwise

until desired cutting depth is achieved. The saw will

until desired cutting depth is achieved. The saw will

repeat to the same depth until re-adjusted.

repeat to the same depth until re-adjusted.

To Re-adjust for Full Cutting Depth:

ToRe-adjust for Full Cutting Depth:

Hold raise/lower switch in the lowering position and

Hold raise/lower switch in the lowering position and

rotate the depth control knob clockwise until saw is

rotate the depth control knob clockwise until saw is

fully lowered. Rotate depth control knob clockwise

fully lowered. Rotate depth control knob clockwise

additional 1 turn.

additional 1 turn.

DEPTH STOP CONTROL

DEPTH STOP CONTROL

MAINTENANCE INSTRUCTIONS

ENGINE

Air filter: Replace outer element when the SYSTEMS

air filter restriction light comes on.STATUS

Replace inner element every fourth outer element.

Oil: Check oil level daily, do not overfill.

Oil type:

See Engine Manual.

Oil Service: Change oil and filter every 125 hours

of operation.

Fuel Filter:

Change fuel filter every 250 hours of operation.

HYDRAULIC SYSTEM

Oil Level: Check reservoir daily. Fill reservoir to

line marked

FULL COLD.

Oil type:

15W-40 premium grade engine oil.

Oil Service:

Change oil and filter every 500 hours of

operation or annually, whichever occurs first.

Reservoir Reservoir is located inside console. Remove

Location:

rear panel for access.

Wheel drive propulsion system, lift pump,

and oil bath bladeshaft share common

hydraulic oil reservoir, thus are maintained

as a single system.

LUBRICATION

Service:

Grease every 125 hrs. of operation.

Type:

Note:

Use premium grade waterproof

EP (extreme pressure) grease.

Locations:

Front axle pivot bearings (2), lift

cylinder pins (2), engine tilt cylinder

pin (1).

DRIVE BELTS

Belt Tension:

Bladeshaft drive belt tension is applied hydraulically when

bladeshaft drive is engaged.

To Adjust

Perform following procedure with saw fully lowered.

Drive Belt

Loosen jam nut on belt tension limiting bolt. Turn belt tension limiting bolt

counterclockwise to create ½” minimum distance between end of bolt and frame.

Start engine and engage belt drive;increase engine speed to full throttle position for

15 seconds minimum.Slow engine speed to idle and shut engine off.Turn belt

tension limiting bolt clockwise until bolt lightly contacts frame.Tighten locknut.

Tension:

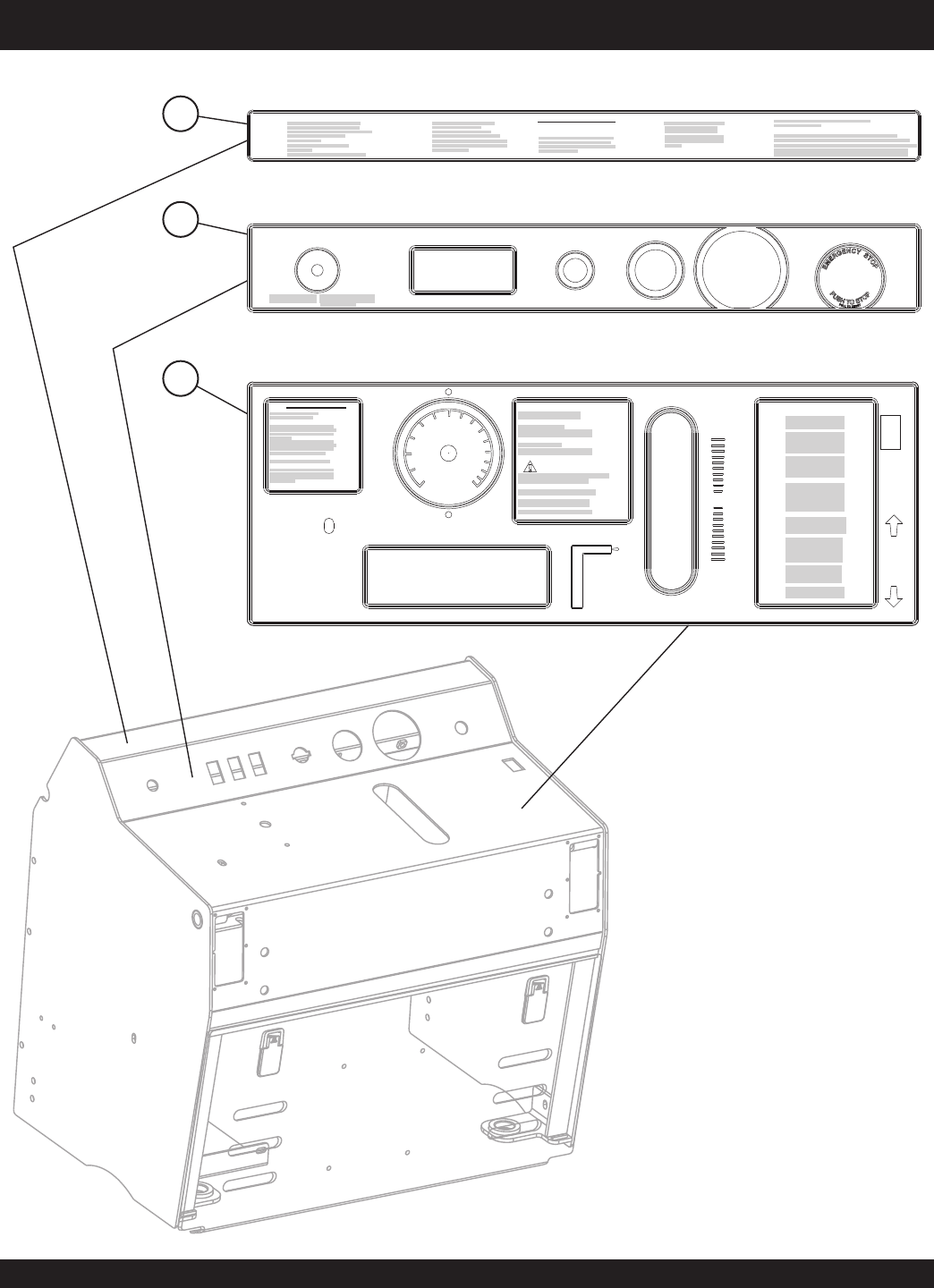

ENGINE WILL NOT CRANK

OR START WHEN E-STOP

BUTTON IS DEPRESSED

TACHOMETER

SYSTEMS STATUS

BLADE SPEED

ENGINE PRE-HEAT

GLOW PLUG

ON

ENGINE

PRE-HEAT

START

OFF

IGNITION SWITCH

ENGAGE

OFF

OFF

BLADESHAFT

DIS-ENGAGE

LIGHTS

ON

AUXILIARY

ON

THROTTLE

TO INCREASE ENGINE SPEED:

TURN KNOB COUNTERCLOCKWISE.

TO REDUCE ENGINE SPEED:

TURN KNOB CLOCKWISE.

FOR QUICK THROTTLE ACTION: DEPRESS RED BUTTON AND

PUSH OR PULL KNOB.

1

2

3

CONTROL PANEL DECALS

CONTROL PANEL DECALS