13

W415-0689 / 06.25.08

Closing the air shutter will cause

a more yellow fl ame, but can

lead to carboning. Opening the

air shutter will cause a more

blue fl ame, but can cause fl ame

lifting from the burner. The

flame may not appear yellow

immediately; allow 15 to 30

minutes for the fi nal fl ame color

to be established.

NOTE: It is important that the venturi sits down tight on

the orifi ce. The burner is adjustable up/down to ensure

this. The electrode sensors should be located 1/4” above

the burner for proper operation.

ADJUSTMENTS

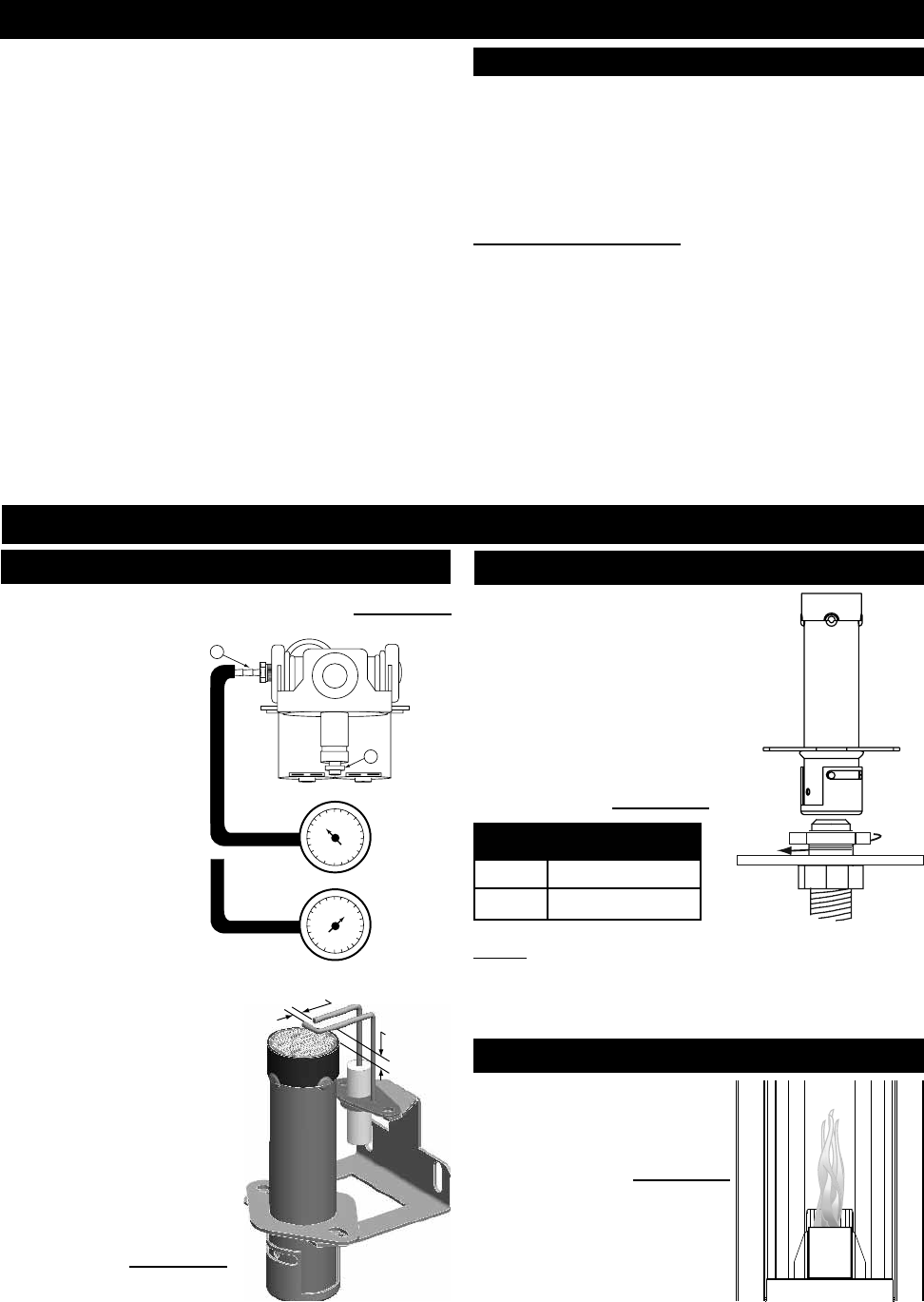

GAS PRESSURE ADJUSTMENT

VENTURI ADJUSTMENT

ORIFICE

VENTURI

BURNER

AIR

SHUTTER

OPENING

FIGURE 21

AIR SHUTTER OPENINGS

LP 3/16” DIA

NG 1/16” DIA

Outlet pressure can be

adjusted if not measuring

3.5” W.C. (NG) or 10.0”

W.C. (LP).

1. Pressure can be

checked by removing

cap (A) using

a 3/16 allen key and

replacing it with a 1/8

NPT barb fi tting.

2. Place pressure gauge

tube over the fi tting.

3. Pressure can be

adjusted by removing

cap (B) using a fl at

screwdriver, and

adjusting the nylon plug

with the same screw

driver. Turning the plug in

(clockwise) will increase

the pressure.

FIGURE 20

A

B

1/8

NPT BARB

FITTING

3.5

10

NATURAL

GAS

PROPANE

GAS

PRESSURE

GAUGE

FIGURE 19

TURN OFF THE GAS AND ELECTRICAL POWER BEFORE

SERVICING THE APPLIANCE.

CAUTION: Label all wires prior to disconnection when

servicing controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after servicing.

This appliance should be inspected before use and at

least annually by a qualifi ed service person. The appliance

area must be kept clear and free of combustible materials,

gasoline or other fl ammable vapours and liquids. The fl ow of

combustion and ventilation air must not be obstructed.

1. Keep the control compartment, burner, and air shutter

opening clean by vacuuming or brushing, at least once a

year.

2. Check to see that the main burner ignites when the switch

for the burner is turned on. A 5 second light-up period is

satisfactory. If ignition takes longer, consult your authorized

dealer.

3. Check that the gasketing on the sides and top of the door

are not broken or missing. Replace if necessary.

MAINTENANCE

It is important to periodically

perform a visual check of the

burner fl ame. Compare them to

the illustration provided.

FLAME CHARACTERISTICS

FIGURE 22

• Visually inspect the appliance for carbon buildup.

• Using a small whisk or brush, brush off the excess carbon

and vacuum up or sweep into the garbage.

• Check the fi replace for corrosion of the main burner base.

Cleaning Stainless Steel: Do not use abrasive cleaners

to clean any painted, porcelain or stainless steel parts. To

clean stainless surfaces, use a stainless steel cleaner or a

non-abrasive cleaner. Always wipe in the direction of the grain.

Do not use steel wool, as it will scratch the fi nish. Stainless

steel parts will discolour when heated, usually to a golden or

brown colour. This discoloration is normal and will not affect

the performance of the fi replace.

CLEANING

1/8”

1/4”