COMPRESSOR LUBRICATION

CAUTION! Do not operate without lubricant or with inadequate lubricant.

Use of compressor without lubricant or inadequate lubricant voids all warranties.

Synthetic Lubricants

Synthetic lubricants are recommended after 50 hour break-in. Compressor life is greatly increased with the

use of synthetic lubricants. CAUTION! If you will be using synthetic lubricant, all downstream piping material

and system components must be compatible.

Suitable Viton, Teflon, Epoxy (Glass Filled), Oil Resistant Alkyd, Fluorosilicone, Flourocarbon,

Polysulfide, 2-Component Urethane, Nylon, Delrin, Celcon, High Nitrile Rubber (Buna N. NBR more

than 36 Acrylonite), Polyurethane, Polyethylene, Epichlorohydrin, Polyacrylate, Melamine,

Polypropylene, Baked Phenolics, Epoxy, Modified Alkyds

( indicates trademark of DuPont Corporation)

Not Recommended

Neoprene, Natural Rubber, SBR Rubber, Acrylic Paint, Lacquer, Varnish, Polystyrene, PVC, ABS,

Polycarbonite, Cellulose Acetate, Latex, EPR, Acrylics, Phenoxy, Polysulfones, Styrene Acrylonitile

(San), Butyl

Alternate Lubricants.

You may use petroleum-based lubricant that is premium quality, does not contain detergents, contains only

anti-rust, anti-oxidation, and anti-foam agents as additives, has a flashpoint of 440°F (227°C) or higher, and

has a auto-ignition point of 650°F (343°C) or higher.

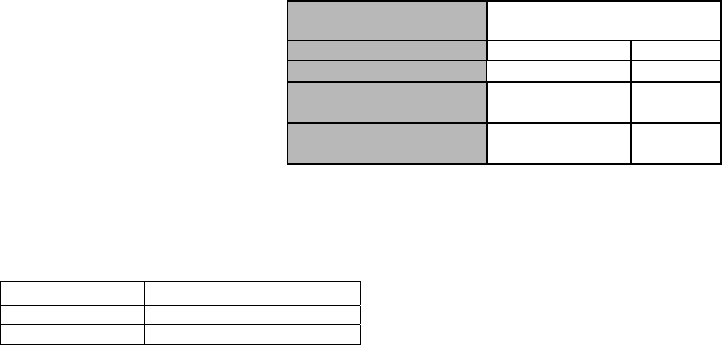

See the petroleum lubricant viscosity table below. The table is intended as a general guide only. Heavy duty

operating conditions require heavier viscosities. Refer specific operating conditions to NorthStar Customer

Service at 1-800-270-0810 Monday - Friday 7:00 AM-5:30 PM, Saturday 7:30 AM-11:30 AM Central Standard

Time.

Temperature around

Compressor

Viscosity Grade

ISO SAE

Below 40°F (4°C)

100 30

40°F to 80°F

(4°C to 27°C)

100 30

80°F to 100°F

(27°C to 37°C)

150 40

Pump Capacities.

Refer to the following table for crankcase capacity

Item number Crankcase Capacity

45929 24 oz.

45930 36 oz.