Installation

CAUTION:

1. INCORRECT ELECTRICAL CONNECTIONS CAN, IN CERTAIN CIRCUMSTANCES, DESTROY THE

ELECTRONIC

OUTPUT CIRCUIT.

2. BEFORE APPLYING ELECTRICAL POWER, MAKE SURE THE SUPPLY VOLTAGE IS TO THE CORRECT

RATING

.

3. THIS A VERY SENSITIVE SENSOR, ONLY APPLY PRESSURE WITHIN THE PRESSURE RANGE.

Mounting

Two M5 threaded holes in the base of the sensor provide mounting points.

Note: The screws must not enter the holes more than 0.4" into the sensor body.

The installed position of the sensor should be away from sudden temperature

variations, shocks and vibrations and should not be close to strong electromagnetic

fields (transformers, motors etc.). The sensor can be mounted in any position, but

mounting at an angle may require zero adjustment. For very low pressure sensors

(less than 2.0 inH

2

O) the recommended mounting is horizontal.

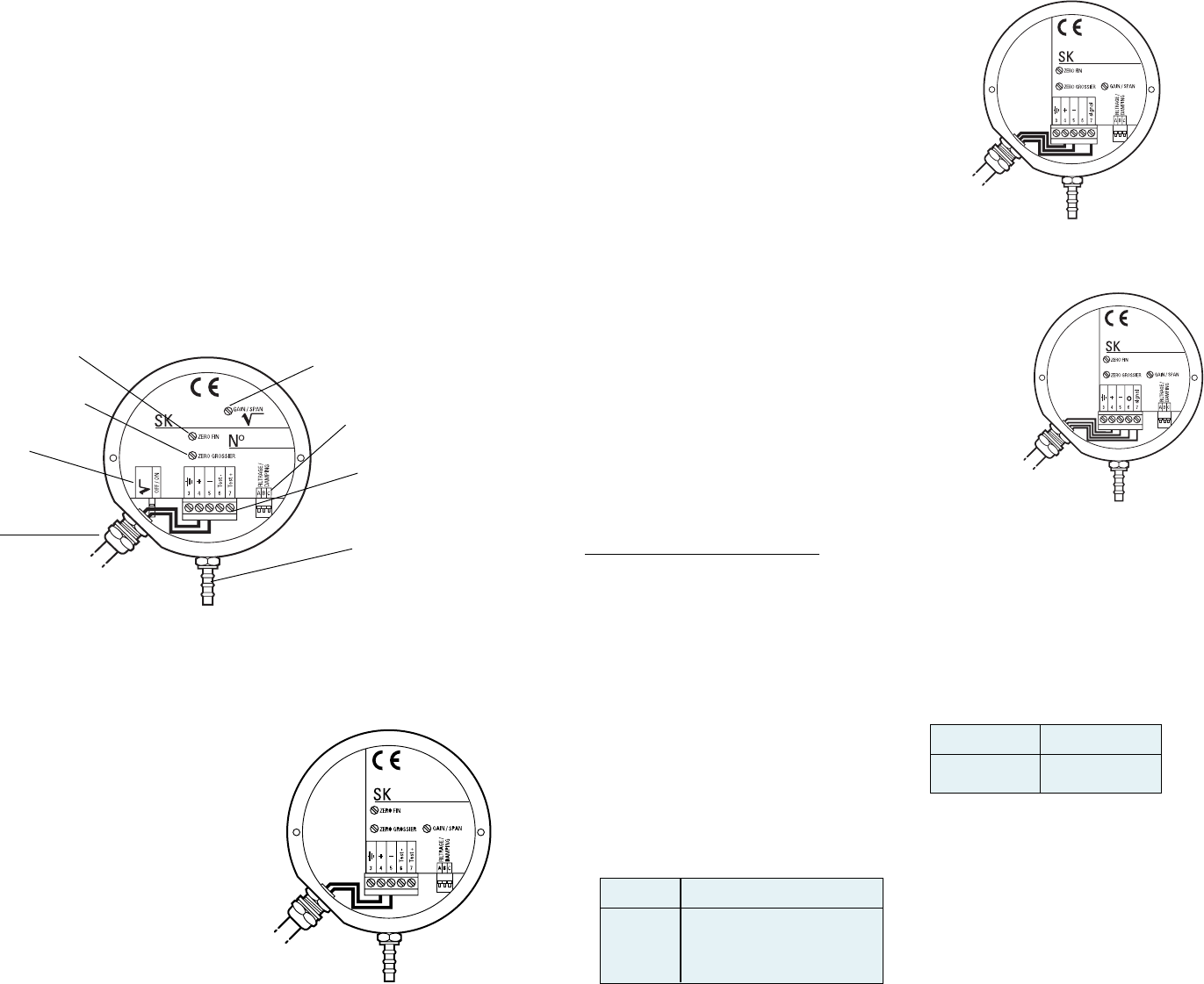

zero adjustment

(fine)

zero adjustment

(coarse)

span adjustment

filter time response

selector switch

terminal connector

block

square root output

selection switch

(optional)

gland nut

(cable entry)

pressure connector

Electromagnetic Interference

To avoid electrical interference, use shielded cable with the shield connected to the

earth ground at both ends. The ground of the sensor can be the casing or the ground

terminal screw.

Electrical connections

PX548 Series (current output)

The maximum allowable load resistance is

calculated to formula:

R Max = 0.05 (V supply - 10) kW

Where: R Max in kW and V in Volts

PX548 Series (Unidirectional voltage output)

Minimum load 2 k

W

Note: Connections 5 and 6 are common

If the output cable passes through an area of electrical disturbance, use a

recommended load impedance of between 2 kW and 10 kW . Connect the load

resistance between the wires corresponding to signal and - terminal at a point

furthest from the sensor.

PX548 Series bidirectional operation using bipolar

power supply (±12 Vdc) with bidirectional output

(0±5 Vdc or 0±2.5 Vdc)

Minimum load 1 k

W

Pressure connections

The high pressure connector is marked

+

and the low pressure connector is marked

–.

Purging or de-gasing the sensor

Two 5 mm hexagonal socket bleed screws are located on the outer casing and can be

loosened to bleed the two pressure connectors. Make sure that these screws are

tightened after this operation.

Note: It is possible to changeover the bleed screws and pressure connectors

enabling easier access or permitting installation in a difficult position.

Square root output option

This option only applies to the LPX 5000 sensor with 4 to 20 mA two wire connection

and the square root electronics assembly fitted. A switch next to the terminal block

selects the output mode.

Switch Output mode

OFF Linear

ON Square root

Internal detail

Filter response time

The filter response time of the sensor, additional to the built-in response time of 10

milliseconds (approximately), can be set using the three switches next to the

terminal connector. Using combinations of the switches can set different times.

Note: A hollow point is visible when a switch is in the 'on' position.

Example:

Switch A+B = 600 milliseconds

Switch Filter response time

A 200 milliseconds

B 400 milliseconds

C 1 second

Connect the power supply to + for positive, - for negative,

and 0 for neutral; connect the output to signal for positive

and 0 for negative signal.