USING THE GRINDER

WARNING

The grinding wheel can fly apart and cause injury. Grinding wheels must always be checked for

cracked for cracks or imperfections. This is done with the "ring test". Tap the wheel gently near

the outer rim with the handle of a screwdriver. You should hear a clear bell-like ring. If a dull thud

occurs, do not use the wheel. The wheel may be damaged and could come apart during operation.

CAUTION: Always wear ANSI-approved safety glasses when grinding.

1. Always bring the workpiece into the wheel gently, without jarring.

2. The workpiece will quickly become heated; therefore, frequent quenching in water is required.

3. When grinding high speed steels such as drill and tool bits, avoid high temperature buildup as

this can affect the temper of the steel.

4. For small workpieces such as drill bits or chisels, avoid applying pressure to the wheel at a high

angle that could cause the workpiece to become lodged between the tool rest and the wheel.

5. When using the Flexible Shaft, be sure the Grinder is turned OFF and wait for it to stop before

setting down the Flexible Shaft.

MAINTENANCE

Dressing the Grinding Wheel

Note: New wheels frequently are not true and during operation will often become grooved, glazed

(build up), out of round, or misshapen. You will need a grinding wheel dresser for this operation.

1. Stand to the side of the wheel for this operation.

2. If the wheel is new let it run for a minute with no load. If the wheel runs straight and true you will

not need to dress it prior to operation. If it dose not, proceed with the following instructions.

3. If you are using a "pistol grip" dresser, grip the handle firmly with one hand and the arm of t

he dresser with the other. Allow the wheel to reach full speed. Use the tool rest to support your

hand and the dresser, and evenly apply the dresser to all surfaces of the wheel. The wheel can be

dressed in a few minutes.

4. If you are using an "inline" dresser, hold the handle firmly, put the dresser on the tool test so

that its wheels can move freely (i.e., the exposed part of the wheel should be facing up ). Let the

wheel reach full speed and apply the dresser evenly to all surfaces.

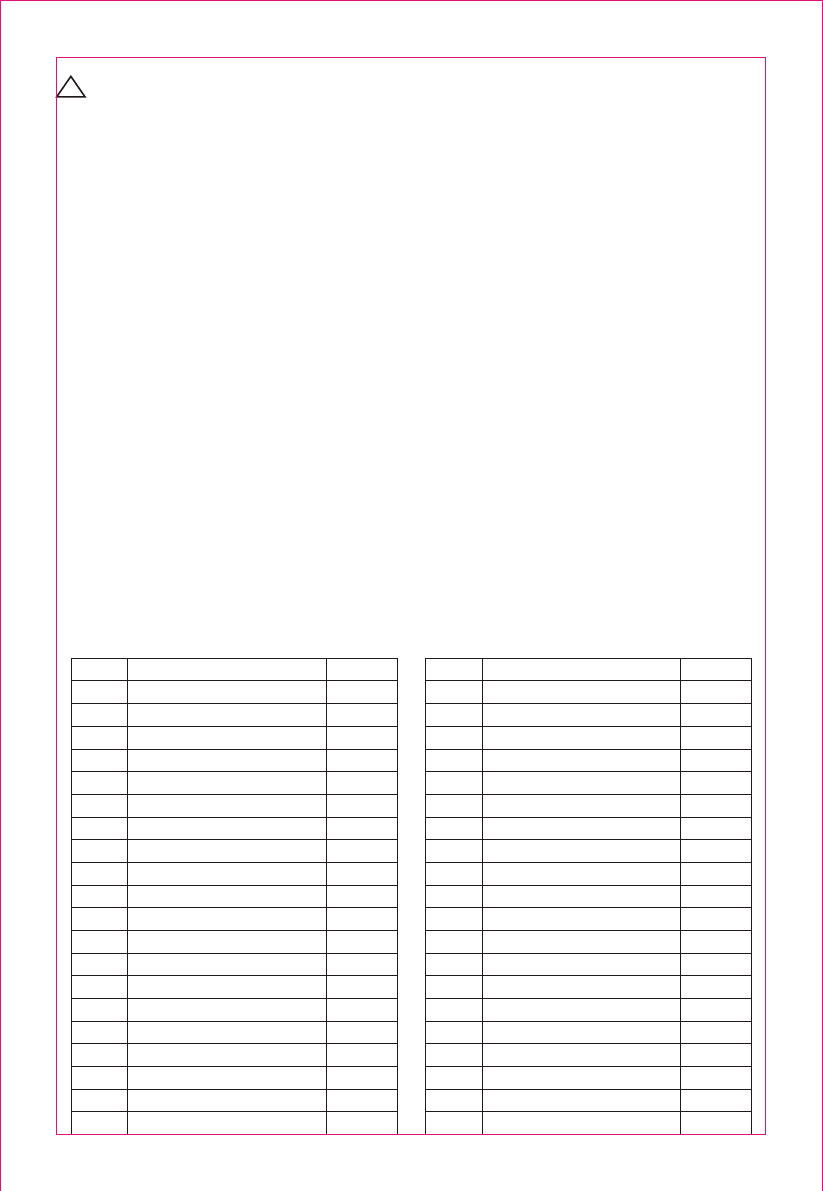

PART LIST

!

Part No.

Quantity

Description

Part No.

Quantity

Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Left Nut M10

Wheel Pushing Ring

Polishing Wheel

Nut M4

Spring Washer M4

Flat Washer (4.3x12x1)

Steel Sleeve

Wheel Cover

Bearing Cover

Brush Cover

Bearing

Brush

Motor Housing

Flat Washer (4.3x8x0.5)

Short Sleeve

Brush Holder

Long Sleeve

Stator

Stator Bolt

Snap Ring

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

Plastic Shield

Lock Nut M4

Plastic Shield Mounting Plate

Flat Washer

Spring Washer

Pan Head Screw M6x20

Pan Head Screw M4x40

Cover

Grinding Wheel

Gasket

Nut M10

Flexible Shaft Connector

Rotating Guard

Wheel Cover

Pan Head Screw M5x10

Flexible Shaft Connector Nut

Knob

Nut M10

Washer

Switch

2

2

2

2

2

2

2

1

1

2

1

1

1

1

1

1

1

1

1

1

1

4

1

6

13

4

2

1

1

2

1

2

1

9

2

1

2

1

2

2

3 of 5