LUBRICATION

Before EACH SESSION, we recommend you check the tables

for slop (easy to x—see step 19 on page 14) and lubricate

the ways with aTeon based dry-lm lubrication. You want your

tables to slide as smoothly as possible. For example, at trade

shows, we lubricate the ways three or four times over an eight

hour period.

Please review the lubrication guide on page 19 for all other lu-

brication locations (this is done once or twice a year depending

on use.)

ASSEMBLY

Step-by-step assembly instructions are included in this Users

Guide. Please contact us if you have any difculties assembling

the Jointmaker Pro. We also have posted on our website videos

showing how we align the blade to the ways and proper table

adjustments. They are not difcult to do but the videos may in-

crease your understanding of these two important adjustments.

Your Jointmaker Pro is fully warranted for defects in workman-

ship. Please notify us immediately if you have encountered ad-

efective component. We will replace it immediately.

CALIBRATION

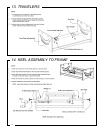

LINEAR TABLE ADJUSTMENTS The Jointmaker Pro was

designed to perform as quietly as possible. The two dovetailed

aluminum rails on each side of the blade are xed in place by

the front and back plates—they are not adjustable. Underneath

each sliding table are two acetyl dovetailed sliders. The slider

closest to the saw blade on each table is xed (non-adjustable).

The acetyl slider furthest from the saw blade on each table is

adjustable and when properly tensioned, both tables will slide

smoothly without any lateral slop. You will periodically adjust the

tension on these two ways over time for optimal performance

—this process usually takes two or three minutes and is fully

demonstrated in the assembly video.

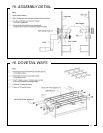

SAW GUIDES The saw blade of the Jointmaker Pro moves

up and down between two blade guides that literally pinch the

blade. One guide is black, the other is blue. Once assembled,

the blue guide is the only guide that is adjusted when chang-

ing between blades of different thicknesses. The black guide is

never adjusted.

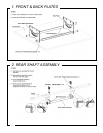

FRONT AND BACK PLATE TRAVELERS The saw blade and

the components that raise and lower the blade are attached to

an aluminum keel. The keel is attached to acetal travelers that

allow the blade to tilt up to 45 degrees in either direction by rid-

ing in arcs milled into the front and back plates.

The two acetyl travelers must glide in the front and back plates

without any slop. There are two nylon set screws in each trav-

eler that allow for this adjustment. If these nylon set screws are

not properly adjusted, the keel will not remain parallel to the

ways.

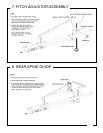

YOUR FIRST CUT

Once your Jointmaker Pro is properly set-up, you are ready to

make your rst cut.

We recommend practicing your rst cut on a small dowel rod,

1/4” – 1/2” in diameter. Set the leading edge of the crosscut

blade slightly below table height, and using the pitch adjus-

tor, raise the rear of the blade until it is slightly taller than your

stock.

Before you make a cut, take a couple of “dry runs” to get a feel

for the resistance of the tables in motion. When comfortable,

hold your material rmly against the fence and with one smooth,

controlled push, cut your stock. You will discover after just a

few passes the rhythm required for incredible results. As the

density/width of your stock changes, you will sense the need to

reduce depth of cut and increase the number of passes. THERE

ARE NO GUIDELINES other than to offer that the feedback you

sense from the cutting action will dictate any adjustments you

will need to make for effortless cutting.

We invite you to visit our website (www.bridgecitytools.com) to

view videos of how we cut different materials.

YOUR EXPERIENCES WITH THE JOINTMAKER PRO MAT-

TER!

Please share your experiences and ideas regarding the Joint-

maker Pro with fellow users! This new and exciting tool is capa-

ble of extraordinary applications, some that may be understood

only by dedicated users. Please share and/or inquire by partici-

pating in the user forums located at www.bridgecitytools.com.

Thank you again for your purchase of the jointmaker pro. please

share pictures and stories with us as you employ this remark-

able new tool in your shop!!

John Economaki

President

TOOLS REQUIRED FOR ASSEMBLY

A at table surface is the best place to assemble the

Jointmaker Pro.

#2 Philips Head Screwdriver

Small Hammer

9/16” Open ended wrench or Adjustable Wrench

Needle Nose Pliers

3