14

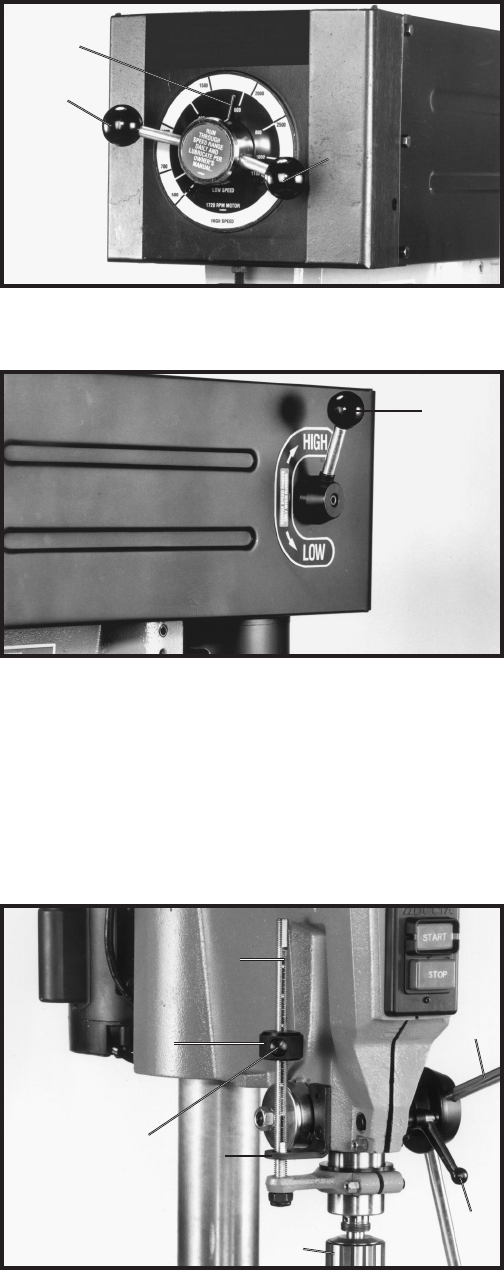

VARIABLE SPEED CONTROL

DO NOT turn variable speed pilot wheel handles (A) Fig.

28, unless motor is running to avoid putting unnecessary

strain on the drive belts and pulleys. The pilot wheel

handles (A) are turned clockwise to increase speed and

counterclockwise to decrease speed. When changing

speeds, the pointer (B) will indicate the speed of the drill

press.

Fig. 28

A

A

B

SPEED RANGE CONTROL

The speed range control lever (A) Fig. 29, MUST NOT

be moved except when the motor is running. When the

handle (A) is in the up “HIGH” position, the speed range

is 500 to 3200 RPM; and when the handle (A) is in the

“LOW” position, the speed range is 150 and 1100 RPM.

Fig. 29

A

Fig. 30

D

DRILLING HOLES TO DEPTH

When a number of holes are to be drilled to exactly the

same depth, the stop nut (A) Fig. 30, on the threaded

stop rod (B) is used as follows:

1. Lower the chuck (C) Fig. 30, and drill bit to the depth

you wish the drill bit to be by rotating the pinion shaft

handles (D). Then lock the quill in position by tightening

quill locking lever (E). NOTE: Quill locking lever (E) is

spring-loaded and can be repositioned by pulling out on

the handle and repositioning the hub of the handle on

the nut located underneath the hub.

2. Depress spring-loaded button (F) Fig. 30, and rapidly

move stop nut (A) until bottom of nut (A) contacts stop

(G). While holding the pinion shaft handle (D) Fig. 30,

loosen the quill locking lever (E), allow the chuck (C) and

the quill, to return to the up position by gradually

allowing the pinon shaft handles to rotate to the up

position.

3. Drill a test hole to check the adjustment and readjust

if necessary by rotating stop nut (A) Fig. 30, for fine ad-

justment. It is not necessary to depress button (F) while

rotating stop nut (A) for fine adjustment.

C

E

F

A

G

B