9

ATTACHING THE AUXILIARY HANDLE

Hold the auxiliary handle as illustrated in Fig. 6. This grip

helps you resist the rotational force and prevents accidental electrical

shock, should you accidentally drill into a live wire. Use the auxiliary

handle during all drilling operations.

Disconnect tool from power source.

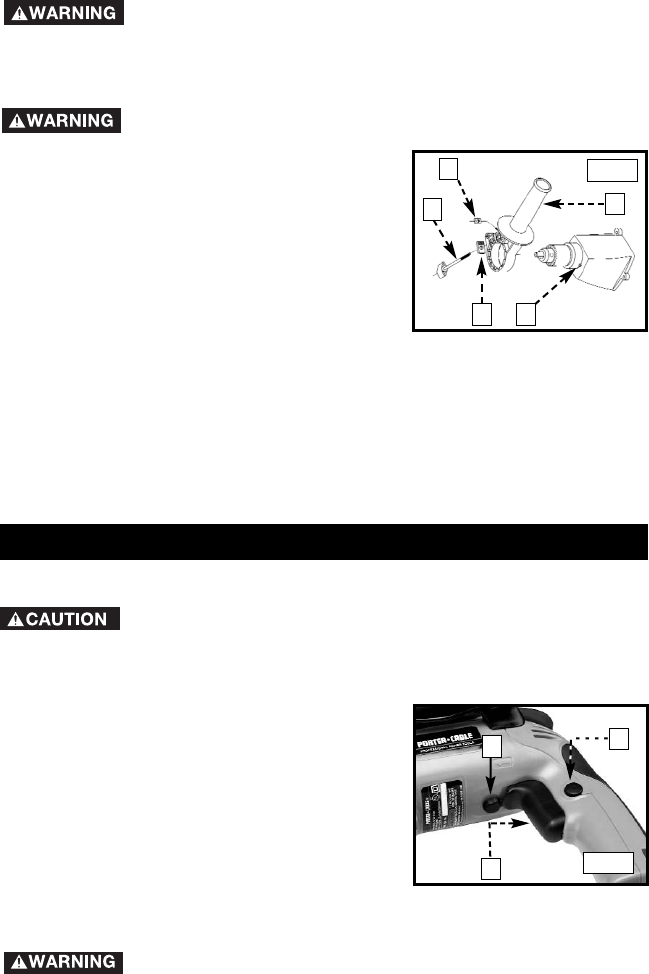

1. Insert the square nut (A) Fig. 3 into the

recess in the auxiliary handle (B).

2. Position the clamping plate (C) on the

auxiliary handle with the serations over

the hex opening.

3. Insert the clamping screw (D) through

the clamping plate (C) and the auxiliary

handle (B), and thread it into the nut (A).

Do not tighten completely.

4. Slide the auxiliary handle assembly over the chuck and on the front of

the housing.

5. Locate the handle in the desired position and align the recesses in the

handle to engage the bosses (F) Fig. 3 on the housing. The handle may

be located in any one of 12 positions 360° around the housing.

6. Tighten the clamping screw (D) securely.

A

B

C

D

E

TO START AND STOP THE DRILL

Confirm that the switch is “OFF”. Make sure that the power

circuit voltage is the same as that shown on the specification plate. Connect

the drill to the power circuit.

1. Squeeze the trigger switch (A) Fig. 4 to start the motor. Release the

trigger to stop the motor.

2. A lock button (B) Fig. 4 is provided to

keep motor running without holding the

trigger switch “ON”. To lock the trigger

switch “ON”, squeeze the trigger as far

as it will go, push in the lock button and

release the trigger. To unlock the lock

button, squeeze the trigger and release,

leaving the lock button free to spring out.

NOTE: The lock button can be engaged ONLY when the drill is running at

maximum speed.

Never use the lock button when the drill may have to be

stopped suddenly.

Fig. 3

OPERATION

A

C

B

Fig. 4