8

ELEVATING CRANK HANDLE

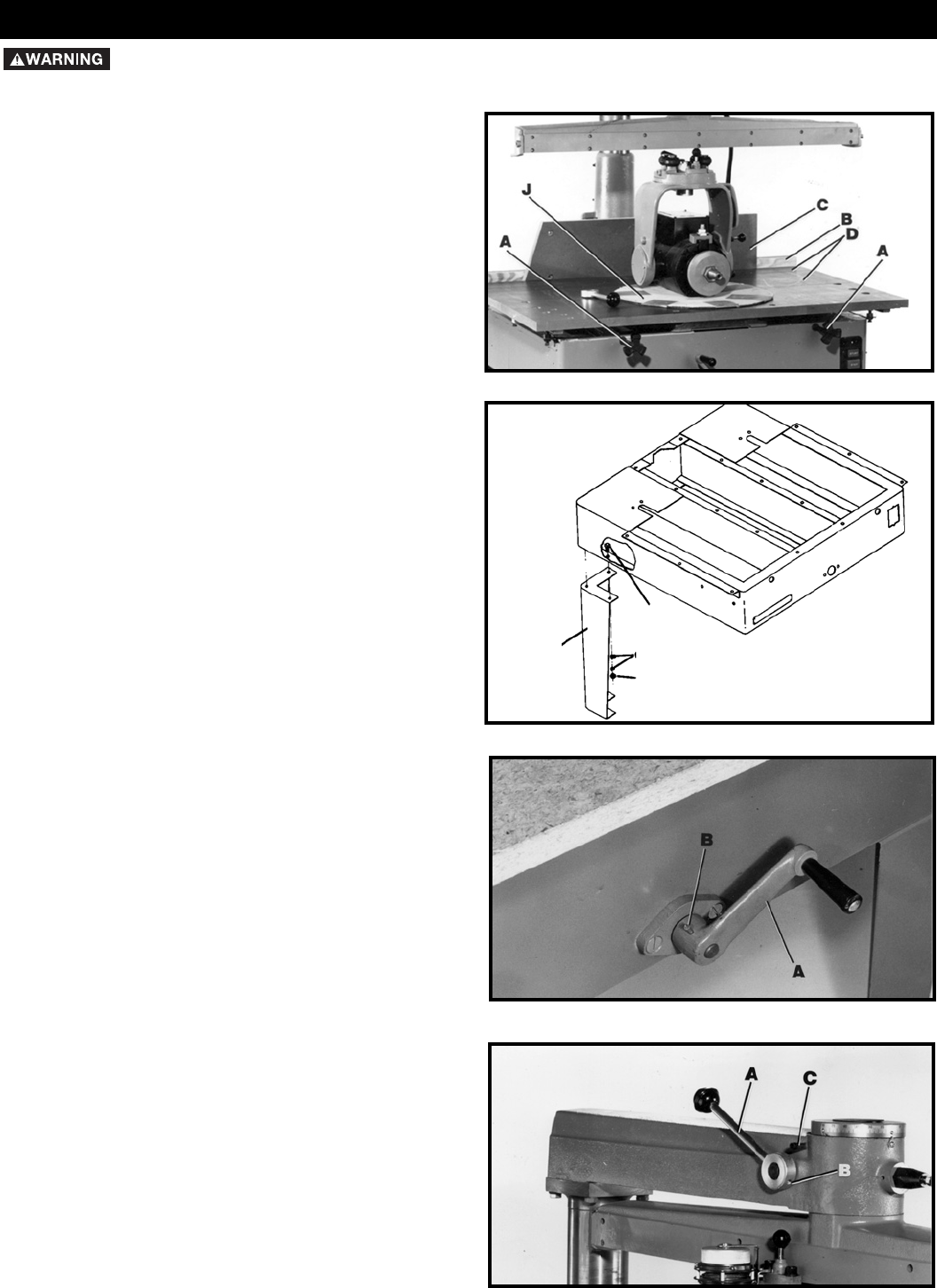

Assemble elevating crank handle (A) Fig. 6 to rod in

front of base using the roll pin (B).

TRACK-ARM LOCK

Assemble track-arm lock handle (A) to the overarm (Fig.

7), and tighten set screw (B). Lock handle (A) should be

tight when in the position shown in Fig. 7, and loose

when pulled forward and resting against stop (C).

Fig. 6

Fig. 7

ASSEMBLY

SELECTING FLOOR SPACE

Before unpacking, determine exactly where you want to

set up the machine. It is highly desirable to locate the

machine against the wall where it will be out of the way

and will actually facilitate material handling through the

shop.

UNPACKING AND ASSEMBLING

LEGS TO BASE

IMPORTANT: Remove the carton from the machine.

Remove bolts that fasten the machine to the skid.

IMPORTANT: To gain access to the four bolts that

fasten the saw to the wooden shipping skid, loosen two

table lock knobs (A) Fig. 4. Remove fence (B), angled

front table board (C) and at least two table boards (D).

Do not remove the packing material around the motor at

this time.

Mechanically lift the machine using a forklift and lifting

straps, and support the machine. Attach the four steel

legs (E) Fig. 5, to each corner of the base using twelve

3/8-16x1" hex head screws (F), 3/8" flat washers (G),

and 3/8" lockwashers (I) and 3/8-16 hex nuts (H).

Remove the packing material from around the motor.

The motor will be positioned on the table as shown in

Fig. 4.

Fig. 4

Fig. 5

E

F

G

H

ASSEMBLY TOOLS REQUIRED

ASSEMBLY TIME ESTIMATE-

4 to 6 hours

* 1/16" Open End Wrench (supplied)

* Roller Head Wrench (1)

* 9/16” and 3/8” open end or socket wrenches (not

included)

FOR YOUR OWN SAFETY, DO NOT CONNECT THE MACHINE TO THE POWER SOURCE UNTIL THE

MACHINE IS COMPLETELY ASSEMBLED AND YOU READ AND UNDERSTAND THE ENTIRE INSTRUCTION MANUAL.